Cleaning Collet Chuck Extensions

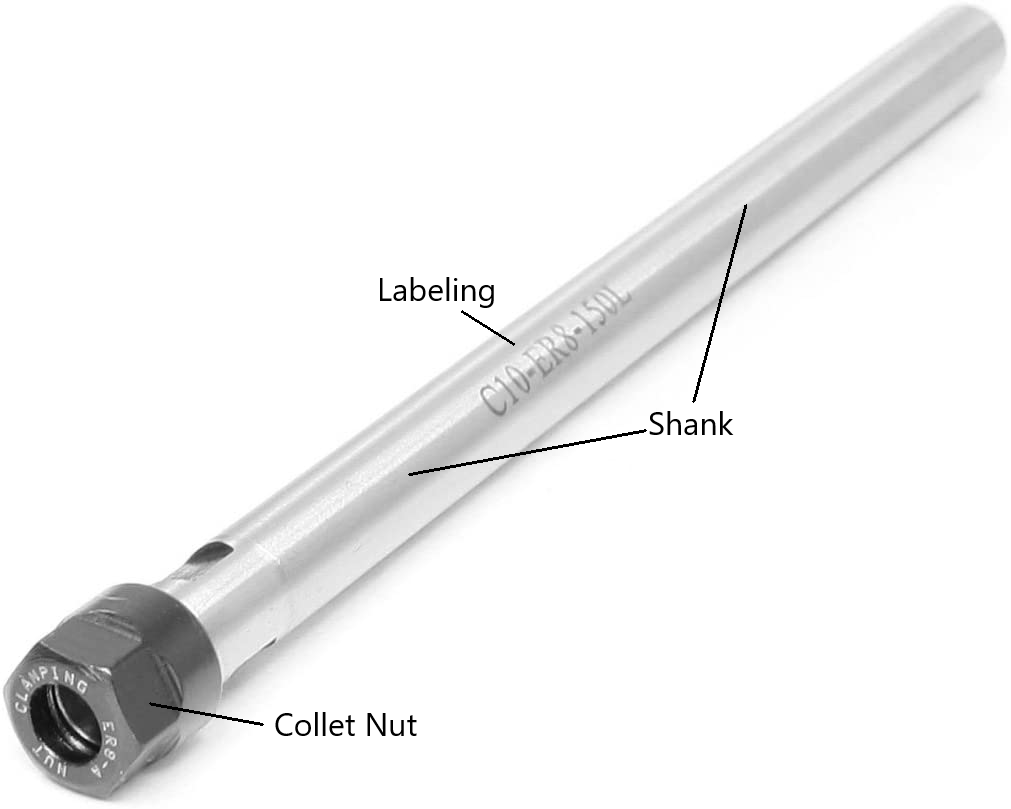

Use WD-40 and a Scotch-Brite pad to remove any rust or residue, being careful not to remove any labeling. Wipe down with a dry rag before taking pictures.

Picturing Collet Chuck Extensions

Click here for info on how to upload pictures

1st Picture: A three-quarters (or "3-D") angle of the extension, with the collet nut pointed toward the camera.

2nd Picture: A side view of the extension, with a tape measure at the bottom of the frame to provide size reference. Make sure there is sufficient space between the item and the tape measure so that the tape measure is not covering up any part of the item. If there is labeling, it should be visible and readable (i.e., right-side up) if possible. Any packaging should be included in this picture as well.

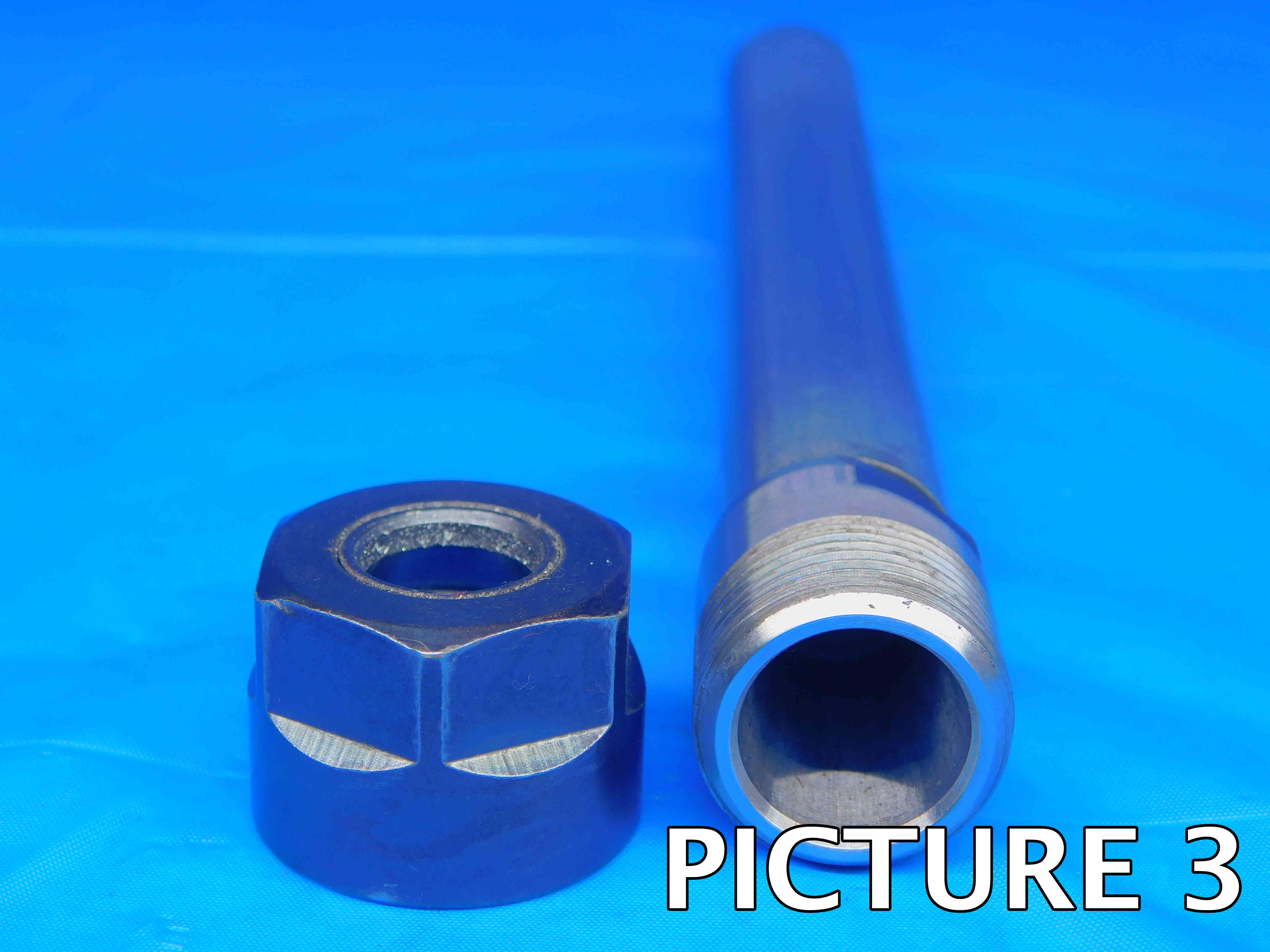

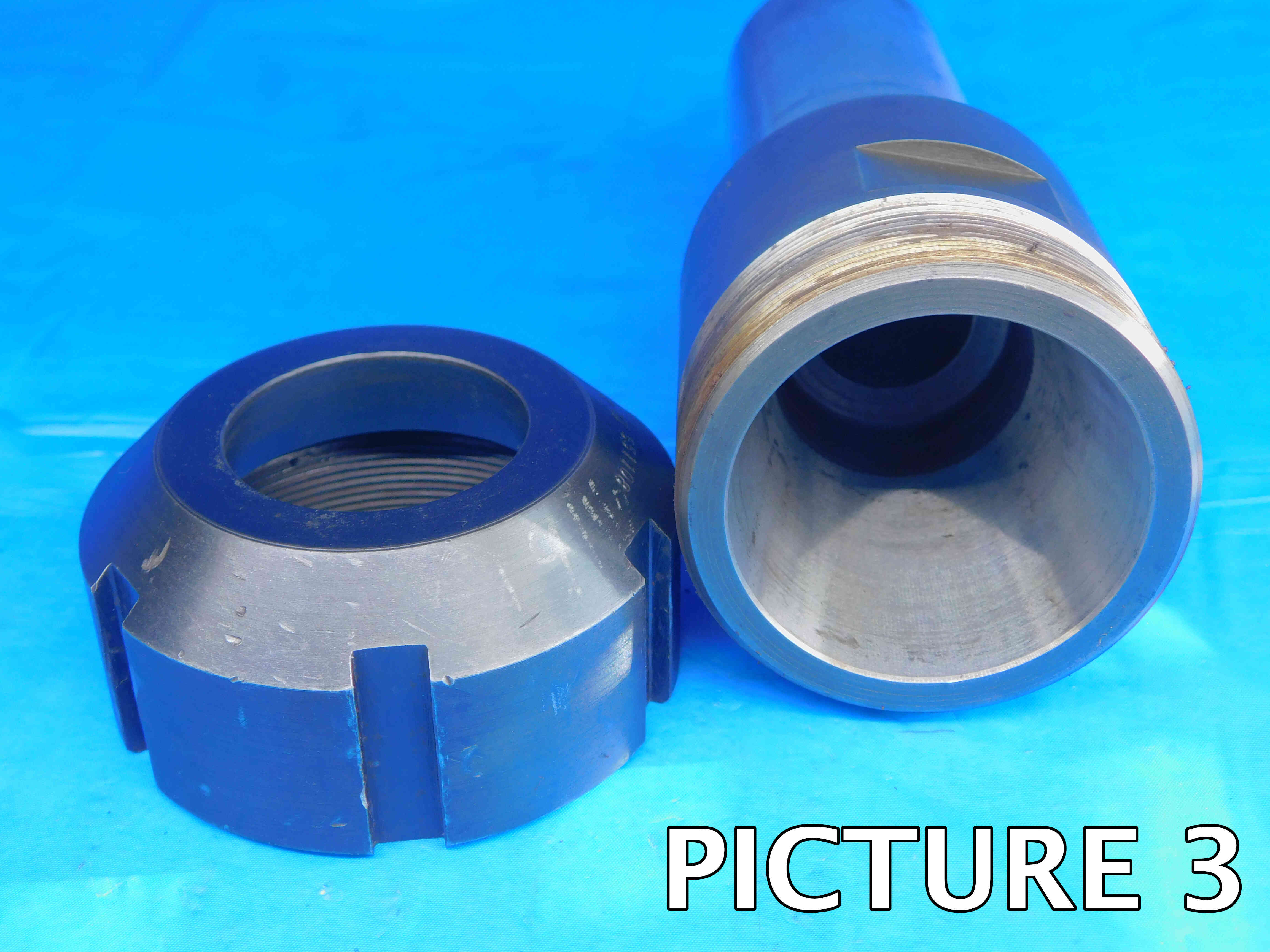

3rd Picture: A close-up, head-on shot of the working end with the nut removed (if possible - it may be stuck and not easily removed). The nut should be included in this shot as well, as shown in the example pictures below. Any packaging should also be included in this picture.

4th Picture: A close-up shot of the labeling. Depending on where the labeling is located, this may require more than one picture. If there is no labeling, skip this picture.

Note: Collet nuts often have their own labeling which is often unrelated to the chuck extension itself. For Picture #4, we are looking specifically for labeling on the chuck extension.

Additional Pictures: Any damage or modifications must be clearly pictured. Use a pen to point to the damaged / modified areas. Refer to the first set of pictures below for an example. Also, if there are any flat sections on the shank which are not clearly visible in the previous pictures, include an additional picture showing the flats. If you think you may need an additional picture for any other reason, contact your trainer to see if it is necessary.

Please refer to the examples below:

Listing Collet Chuck Extensions

If there is no brand labeled, click the "unlabeled" button to the right of this cell. Make sure this cell is not left blank, or the listing will not upload properly. Note: Items are often labeled with the country of origin (USA, China, Japan, Poland, etc). This should NOT be entered as the brand, and furthermore should not be included in the listing at all EXCEPT for USA which can be used as a filler.

Please note that the nut may be a different brand from the rest of the chuck. In the event of conflicting brands, list the brand labeled on the chuck itself and not the nut.

Part numbers will typically be printed on the shank and will often include information about the type of collet held. There may be a labeling on the nut as well, but we are generally not concerned with this labeling.

If the collet chuck extension is unlabeled, leave this cell blank.

Some collet chucks are used specifically for holding taps. Sometimes these will look very similar to other collet chuck extensions, but often you will encounter quick-change tapping chucks like the ones pictured above. They use quick-change tap collets (shown in the 3rd image above) which are held in place by a "Tang Drive" system and can be quickly removed by pressing the release collar in toward the shank. This is known as "Bilz-Style" because it was developed by the German company Bilz. You may also encounter another style of quick change tapping chucks known as Smith/Valenite-Style. These chucks and collets are made primarily by the companies TM Smith and Valenite, and are very similar to the Bilz-Style with the notable exception that it lacks the tangs, meaning the two systems are not interchangeable. See the images below for an example of Smith/Valenite-style chucks and collets:

Another type of collet chuck to look out for, which appears very similar visually to the Smith/Valenite-style tapping chuck, is the Magic Chuck:

The Magic Chuck uses a special straight collet (shown in the third image above) with a horizontal groove that is locked into place using a similar ball-drive system to the previously described tapping chucks. These are not designed for tapping and are used primarily for drilling. The easiest way to differentiate a Magic Chuck from a Tapping Chuck is measuring the I.D., as a Magic Chuck will always have an I.D. that measures one of the following sizes (which do not line up with any quick-change tap collet sizes): 11/16", 15/16", 1 1/4", 1 11/16", 2 3/8". More information on Magic Collets can be found in the Collet FAQ.

There are two types of tapping chucks: Rigid Tapping Chucks and Tension & Compression Tapping Chucks.

A rigid tapping chuck, like the name implies, has no moving parts besides the release collar and holds a tap rigidly with no extra movement. Rigid tapping is often faster and produces a more accurate thread, but requires precise synchronization between the motion of the machine spindle and the axis moving down the hole - and improper synchronization can lead to torn threads and broken taps.

A tension & compression tapping chuck, meanwhile, has a free-floating head that uses springs to allow a small amount of movement in the tap, compensating for errors as the machine pushes and pulls the tap through the material. Tension & compression tapping chucks tend to be more expensive, and are less useful for working with softer materials which can deform around the tap.

How to tell the difference: On both types of chucks the collar will be able to be pulled out away from the shank (which is how the collet is released), but a tension & compression chuck will also be able to be pushed in toward the shank, while a rigid chuck will not. This is where the "compression" part of tension & compression comes from, and is the easiest way to distinguish the two types since in most cases there will otherwise be no visual differences.

Another type of tapping chuck you may encounter is the Numertap system developed by Parlec:

Numertap

***The collet chuck shown above has a CAT50 tool holder shank, but these can be found as straight shank extensions as well

Numertap chucks use a unique collet, pictured above, which is longer than the Bilz style, does not have tangs, and is held in place by ball bearings on the inside of the receiving chuck. These chucks can be rigid or tension & compression just like Bilz-style chucks.

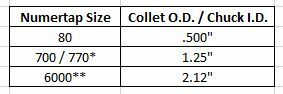

Numertap collets come in a few different sizes, which can be determined by measuring the O.D. of the collet or the I.D. of the chuck, according to the chart below:

*Sizes 700 and 770 are interchangeable

**Numertap 6000 uses a different unique collet which resembles a lathe bushing, shown below:

There are several different types of collets which come in a variety of sizes. Some of the most common collet types include ER, TG, and DA. Be sure to include both the type and size (such as ER32 or DA100). The type of collet held will frequently be labeled, or searching the part number online may lead you to this information.

For more information about collets, including charts for determining collet sizes, refer to the Collets FAQ page.

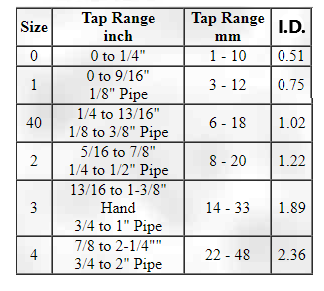

For tapping collet chucks, enter the number size of the tapping collet it holds (#1, #2, etc.). If this information is not labeled, it can be determined by measuring the I.D. of the chuck and comparing to the chart below:

***Sizing is the same for both Bilz-Style and Smith/Valenite-Style collets***

The shank diameter can be measured with calipers and will usually be a common size, however this is a precise measurement and should not be rounded if it is more that .005" off from a fractional size. If a shank measures to an unusual off-size, try converting to millimeters as it may be a metric size.

Collet chucks, particularly tapping collet chucks, will sometimes have an Automotive Shank (pictured below - also called an Auto Shank). This is a threaded shank with a key that drives the shank within a tool holder, and an adjustable collar that travels along the threads to alter the depth at which the tool projects from the tool holder. The shank diameter is still measured with calipers, and the word "Auto" or "Automotive" should be added to the title as a filler.

The overall length is very simple; measure the distance between the farthest two points on the tool. This can be done with handheld calipers or even a tape measure as this does not need to be as precise as other measurements.

The "Filler" section is used to add other relevant information to the title which is not covered by the other sections. Fillers can be a good way to increase a listing's visibility - we always want to include as much information as possible that we think a customer might be searching for in order to make sure that our listing is coming up in their search results.

There is not necessarily one right answer when it comes to fillers, and often it will be up to you to decide what should and should not be added as filler. Collet chucks generally do not require much filler, but some possible fillers include:

-Secondary labeling or branding / product names

-"USA" or "USA Made" for any US Manufacturers (you may need quickly research a brand if you are not sure since this will not always be specifically labeled)

-For tapping chucks: "Quick Change", "Bilz Type"

Note: Keep in mind that titles have a maximum limit of 80 characters.

Additional Specifications & Special Condition

The Additional Specifications section should be used for any secondary labeling or additional measurements that do not fit in the other sections of the listing. There is no character limit here so any relevant information that is not already covered should be included (within reason - we don't want to overload the listing with unnecessary information, so ask your trainer if you are not sure whether or not to include something in this section).

The Special Condition section should be used for any special notes about the item's condition such as damage or modification. Try to be specific when describing the condition, and reference pictures that point out the damage / modification if applicable. For example, "There are two flat sections in the shank - see picture #4 for details." General wear and tear does not need to be mentioned, but anything that will affect the tool's usage should be included here.

Once all information is entered, click here for the next steps.