MODULAR TOOLING SYSTEMS

There are several different types of modular systems which serve as an alternative to the more common connection types like solid end mill and Morse taper. These systems were developed for a variety of reasons, such as minimizing unwanted tool movement or making it easier to quickly change out tools in the middle of a job.

Most modular systems come in a variety of sizes which will often be notated by labeling but can also be determined using certain measurements as described in each section below.

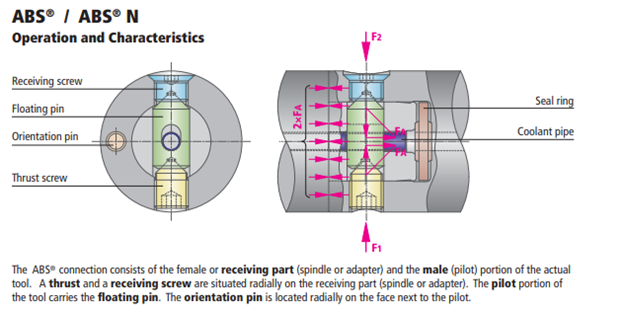

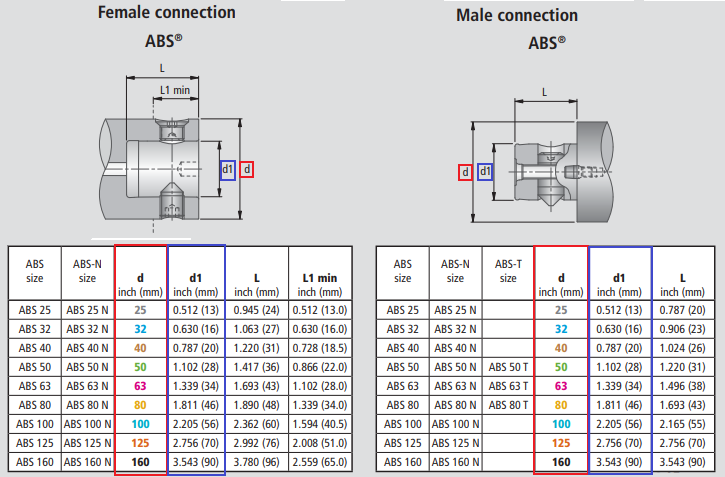

ABS sizes will typically be labeled. If no labeling is present, the size can be determined by measuring d or d1 as shown in the charts below.

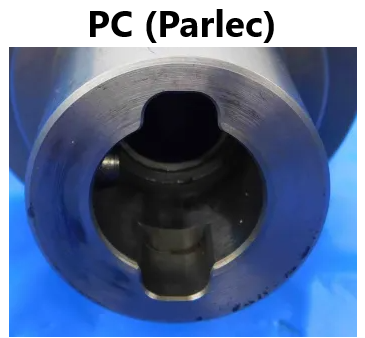

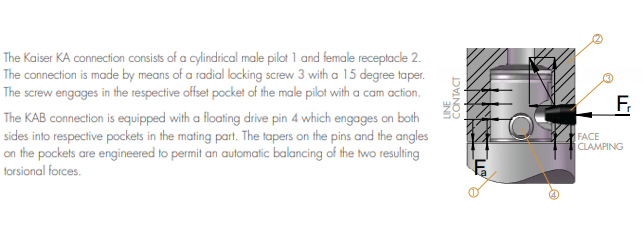

KA/KAB/CK/CKB (KAISER) & PC (PARLEC)

In 2016 Kaiser changed the naming system from KA/KAB to CK/CKB. The specifications did not change – just the names. It is recommended to put both in the title (ex., “KAB6 / CKB6”) because customers may search for either.

The PC modular system developed by Parlec uses the same locking mechanism and size measurements as KA/CK (PC1 = KA1, PC6 = KA6, etc). The locking pin is wider than KA (as can be seen in the pictures above), which means that a Kaiser shank can fit in a Parlec holder, but not the other way around. For this reason it is very important that we do not use KA and PC interchangeably in listings. Make sure to always confirm whether a tool or tool holder is KA or PC and list accordingly.

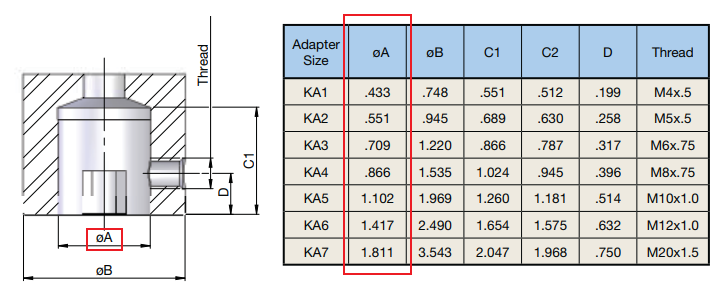

Sizes are frequently not indicated by labeling. They can be most easily determined by measuring ØA as shown in the chart below.

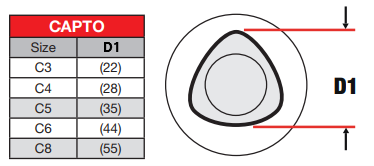

CAPTO connections are easily identified by their distinctive tapered polygon shape. The size will almost always be notated at the very beginning of the labeling – for example, a tool holder labeled with the part number “C6-A390.45-50 090” is a CAPTO size C6. If a tool is unlabeled, the CAPTO size can be determined by measuring D1 (measured in mm) as shown in the chart below.

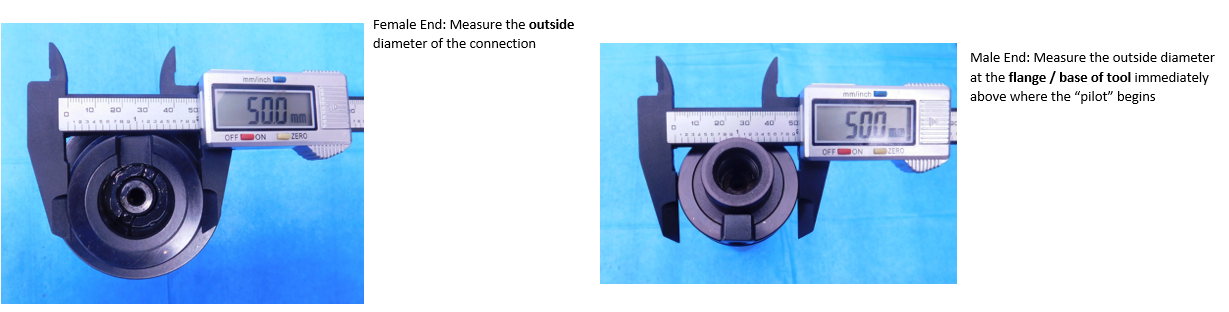

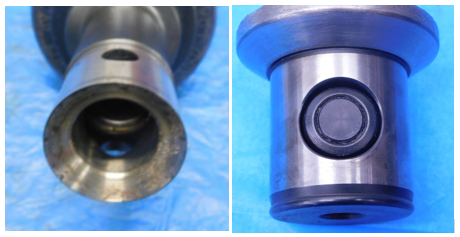

Varilock is an older modular style that is no longer in production (it was replaced by CAPTO) which appears similar to a pilot and key configuration that you would see on a side or face mill. Varilock sizes are almost always notated in labeling as the second to last number. For example, a tool labeled “A391.16-25 63 095M” is a Varilock size 63. If no labeling is present, the size can be determined by measuring the outside diameter as shown in the pictures below. The measurement in mm will equal the Varilock size – these pictured examples both have an O.D. of 50mm, so they are both Varilock size 50.

Varilock sizes include 50, 63, and 80.

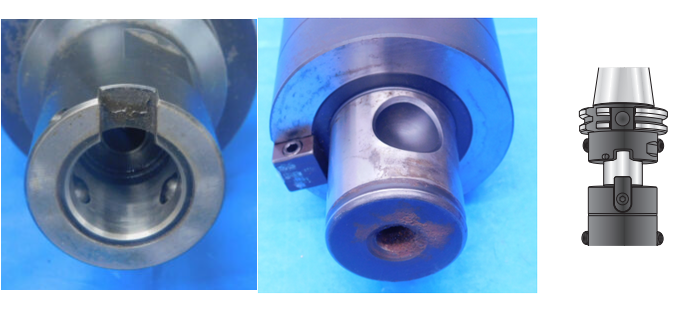

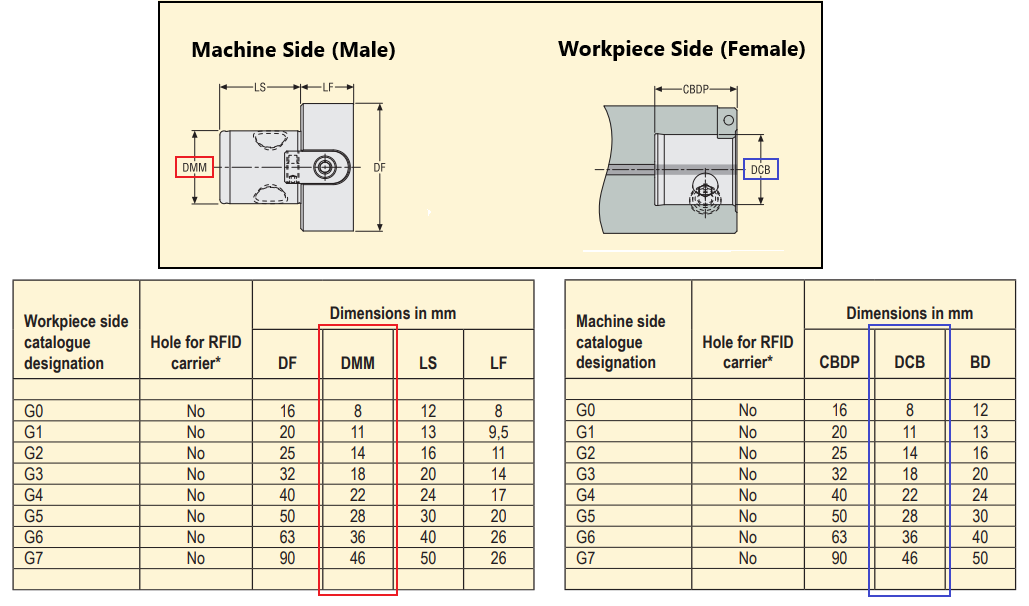

Graflex connections use a very similar pilot-and-key style to Sandvik Varilock. Sizes are typically not indicated by labeling and can be determined by measuring either DMM (male side) or DCB (female side) as shown in the charts below.

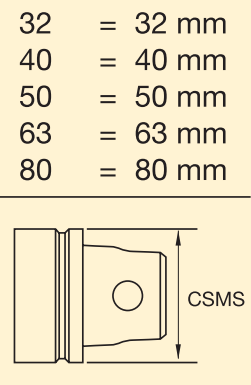

The Kennametal KM clamping system uses a tapered shank and a special "ball track" locking system. The male end shares many visual similarities with an HSK-A tool holder, and sizes are measured the same way as HSK-A: The outer diameter of the flange (in mm) is equal to the KM system size (32mm = KM32, 40mm = KM40, etc.) as shown in the diagram below:

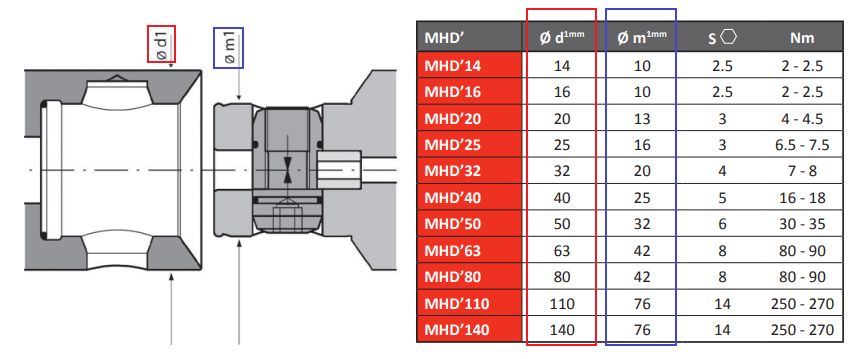

Modulhard (or MHD) uses a radial clamping pin similar to ABS or KAB/CKB, but can be differentiated by the tapered portion that flares out at the end of the connection. Sizes are sometimes indicated by labeling and can be determined by measuring d1 (female side) or m1 (male side) as shown in the chart below.