Use WD-40 and a scotch-brite pad to remove any rust or other residue. The inside of the adapter should be cleaned if possible, but don't worry if you can't get all the way inside it. Wipe down with a dry rag when finished.

Picturing Morse Taper Adapters

Click here for info on how to upload pictures

If you are picturing a single adapter:

1st Picture: A three-quarters (or "3D") angle of the adapter, with the working end toward the camera. Any packaging should be included in this picture.

2nd Picture: A side view of the adapter, with a tape measure at the bottom of the frame to provide size reference. Make sure there is sufficient space between the adapter and the tape measure so that the tape measure is not covering up any part of the adapter. Any packaging should be included in this picture as well.

3rd Picture: A close-up, head-on shot of the working end.

4th Picture: A close-up shot of the labeling. If there is no labeling present, skip this picture.

5th & 6th Pictures: A close-up shot of the tang (both sides). There may be some overlap here, since it is common for labeling to be located on the tang - if that is the case, just picture whichever side is not already present in the labeling picture. These pictures do not apply to adapters which are not Morse Taper on the outside diameter.

Additional Pictures: Any damage or modification to the adapter, particularly around the tang or working end, must be clearly pictured. Use a pen to point to the damaged / modified area. If you believe additional pictures are needed for any other reason, contact your trainer to verify if it is necessary.

Refer to the pictures below for examples:

If you are picturing multiple adapters:

1st Picture: A side view of the adapters, with a tape measure at the bottom of the frame to provide size reference. Make sure there is sufficient space between the adapters and the tape measure so that the tape measure is not covering up any part of the adapter. Any packaging should be included in this picture as well.

2nd Picture: A close-up, head-on shot of the working ends. If you have a particularly large number of adapters, this may require multiple pictures.

3rd Picture: A close-up shot of the labeling. If the adapters are identical, only one label needs to be pictured. Otherwise, try to get all of the labeling in as few shots as possible while still being readable. If there is no labeling present, skip this picture.

4th & 5th Pictures: A close-up shot of the tangs (both sides). Depending on the number of adapters in the lot, this may require more than 2 pictures.

Additional Pictures: Any damage or modification, particularly around the tang or working end, must be clearly pictured. Use a pen to point to the damaged / modified area. If you believe additional pictures are needed for any other reason, contact your trainer to verify if it is necessary.

Refer to the pictures below for examples:

Morse taper adapters will often have a brief labeling explaining the Morse Taper adaption or extension. An example labeling "24106 2-5-H" describes that this is an MT2 (inside / female) to MT5 (outside / male) where the 24106 must be a part number from the manufacturer. Often times this will just be something like "2-2" or "3&4" where the first number describes the inside size & second the outside size.

If there is no brand labeled, click the "Unlabeled" button to the right of the Brand cell. Make sure that the Brand is not left blank, or the listing will not upload properly. Note: Items are often labeled with the country of origin (USA, China, Japan, Poland, etc). This should NOT be entered as the brand, and furthermore should not be included in the listing at all EXCEPT for USA which can be used as a filler.

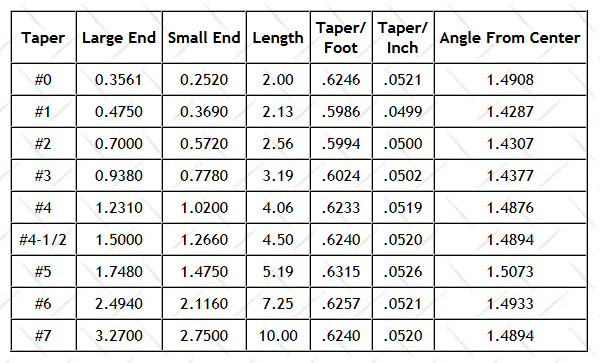

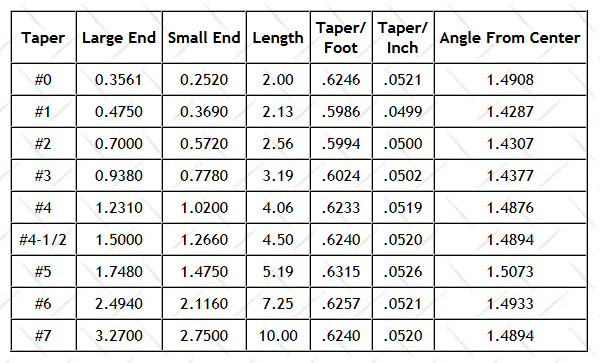

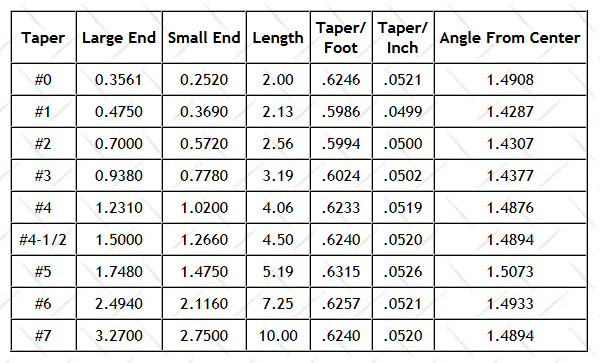

Inside & Outside MT# / Diameter

There are a few different combinations of tapers and straight diameters that you will find on Morse Taper adapters:

Morse Taper / Morse Taper (Different Sizes)

This is the most common type of Morse Taper adapter, with one MT size on the outside and a different MT size on the inside. In the adapter pictured above, the inside is MT2 and the outside is MT3, as can be seen in the "2-3" labeling near the bottom.

The sizes should be entered as "MT#" (Morse Taper #2 = MT2, Morse Taper #4 = MT4, etc.).

In the vast majority of cases, the outside MT size will be larger than the inside MT size. Adapters that go from a smaller outside taper to a larger inside taper do exist, but are very uncommon, and will appear more like the extension shown in the next section.

Morse Taper / Morse Taper (Same Size)

These are extensions which are used to increase the length that a tool projects from the holder. You may run into some adapters that have two distinct sections like this that are not the same taper, so always measure both the inside and outside diameters to confirm rather than making assumptions based on the adapter's appearance.

The sizes should be entered as "MT#" (Morse Taper #2 = MT2, Morse Taper #4 = MT4, etc.).

Another option for Morse Taper adapters is a straight outside diameter with an inside Morse Taper, or vice versa. If the Morse Taper is the inner size, there will be a slot near the bottom like in the picture above.

The Morse Taper size should be entered as "MT#" (Morse Taper #2 = MT2, Morse Taper #4 = MT4, etc.), and the straight diameter will be entered as just a simple number - so for example, if the adapter pictured above has an outside diameter of 1" and an inner size of Morse Taper #2, you would enter the Outside size as 1" and the Inside size as MT2.

Note: When entering a whole-number inch size, always include the " sign. The " sign should not be included for any size including a fraction or decimal. So, for example: If an adapter's outer diameter is exactly one inch, it should be entered as 1" and not just 1. If the O.D. is one and a half inches, it should be entered as 1 1/2 or 1.5 and not 1 1/2" or 1.5".

An item you may run into which is very similar to this type of Morse Taper adapter is the Magic Chuck Collet:

These always have:

1. An outer diameter of 11/16", 15/16", 1 1/4", 1 11/16", or 2 3/8"

2. A Morse Taper inner diameter

3. A horizontal groove about 2/3 of the way down the body, seen in the pictures above

Despite the visual similarity to straight O.D. Morse Taper adapters, these are actually a type of collet. Refer to the Collet FAQ for more information on how to list these.

The overall length of Morse Taper adapters is very simple, simply measure the distance between the farthest two points on the tool. This can be done with handheld calipers or even a tape measure as this does not need to be as precise as other measurements.

If you are listing these as part of a lot (up to 4 pcs per listing), please enter the additional sizes in the space for them in the format: MT(#) TO MT(#) (ex. MT2 TO MT3), or if there is a straight diameter involved you may enter such as: 1" SHANK TO MT3.

The "Filler" section is used to add other relevant information to the title which is not covered by the other sections. Fillers can be a good way to increase a listing's visibility - we always want to include as much information as possible that we think a customer might be searching for in order to make sure that our listing is coming up in their search results.

There is not necessarily one right answer when it comes to fillers, and often it will be up to you to decide what should and should not be added as filler. Morse Taper adapters generally do not require much filler, but some possible fillers include:

-Secondary labeling or branding / product names

-"USA" or "USA Made" for any US Manufacturers (you may need quickly research a brand if you are not sure since this will not always be specifically labeled)

Note: Keep in mind that titles have a maximum limit of 80 characters.

Additional Specifications & Special Condition

The Additional Specifications section should be used for any secondary labeling or additional measurements that do not fit in the other sections of the listing. There is no character limit here so any relevant information that is not already covered should be included (within reason - we don't want to overload the listing with unnecessary information, so ask your trainer if you are not sure whether or not to include something in this section).

The Special Condition section should be used for any special notes about the item's condition such as damage or modification. Try to be specific when describing the condition, and reference pictures that point out the damage / modification if applicable. General wear and tear does not need to be mentioned, but anything that will affect the tool's usage should be included here.

Once all information is entered, click here for the next steps.