ITEMS NEEDED:

GLOVES

TPI GAGES, METRIC & IMPERIAL

CLEAN PANS (2 LARGE, 10 NOT AS LARGE)

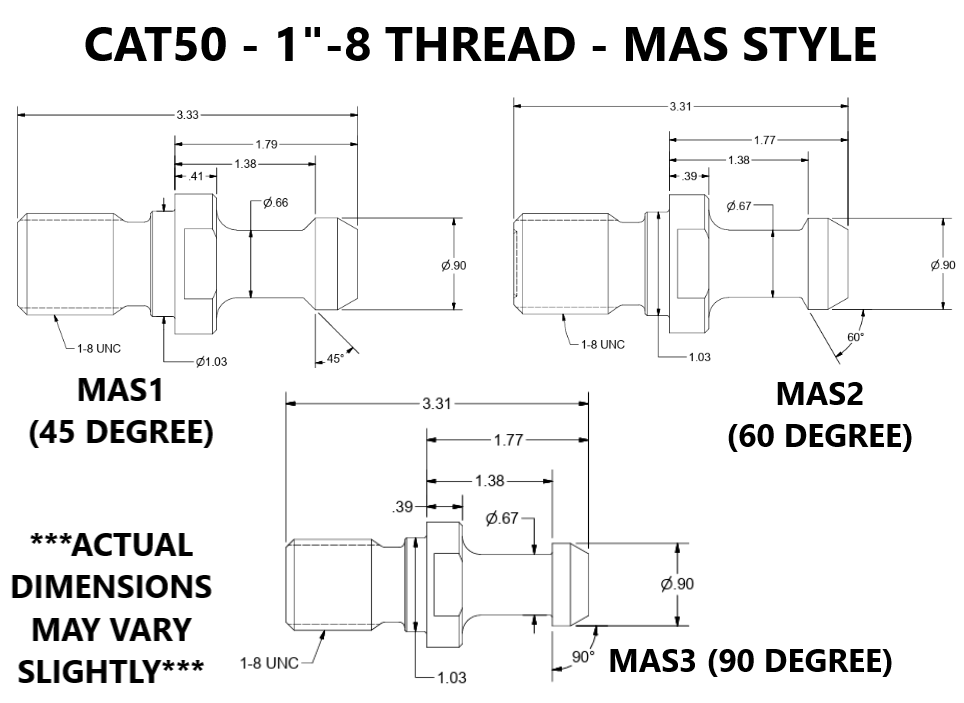

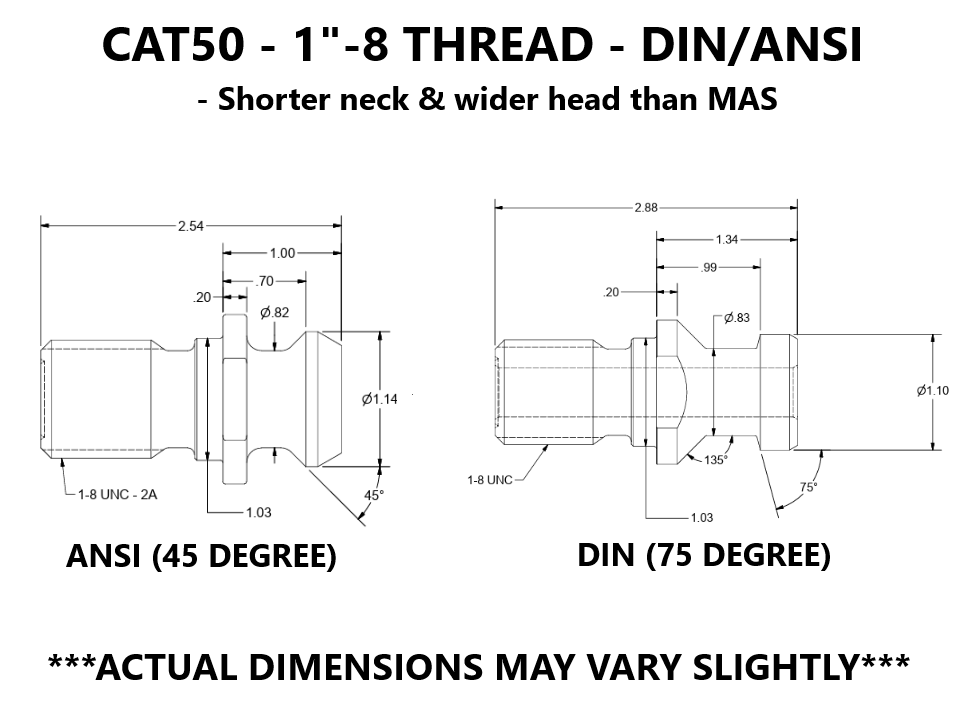

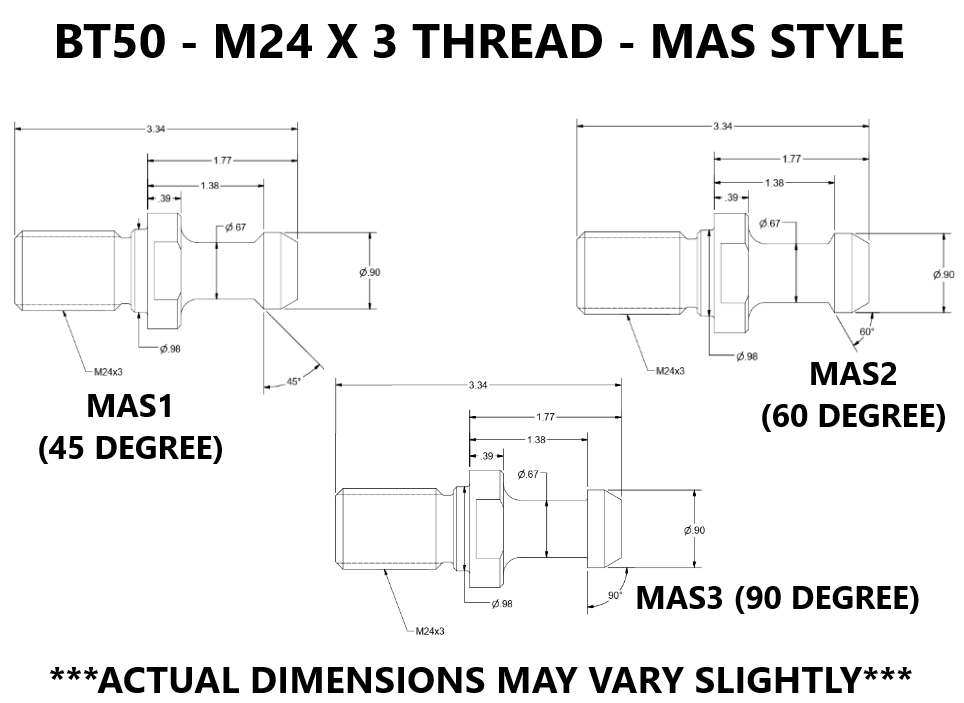

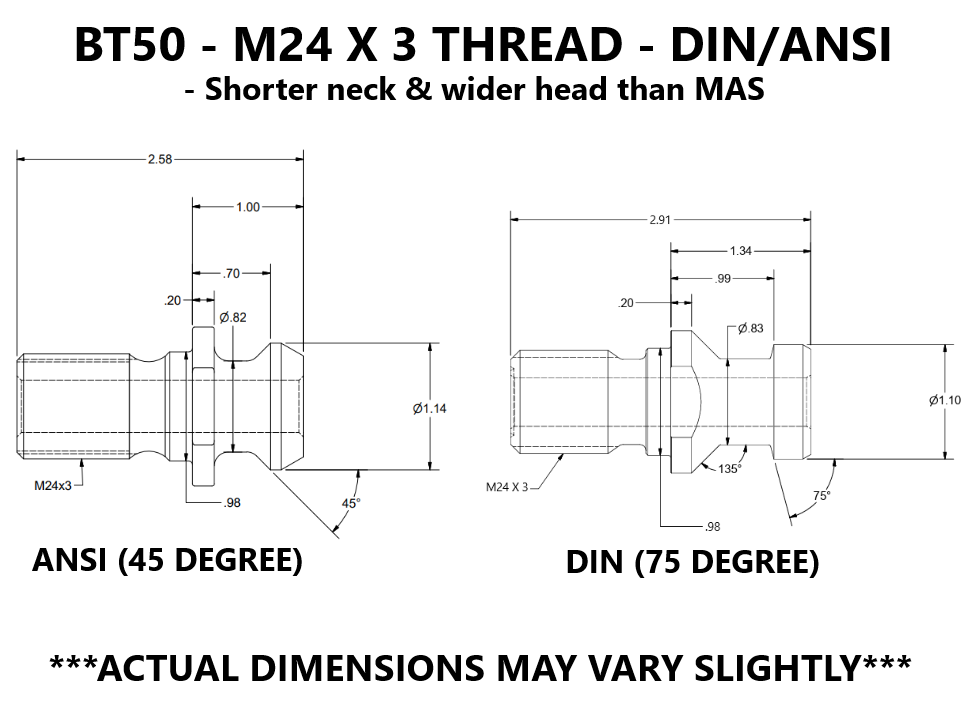

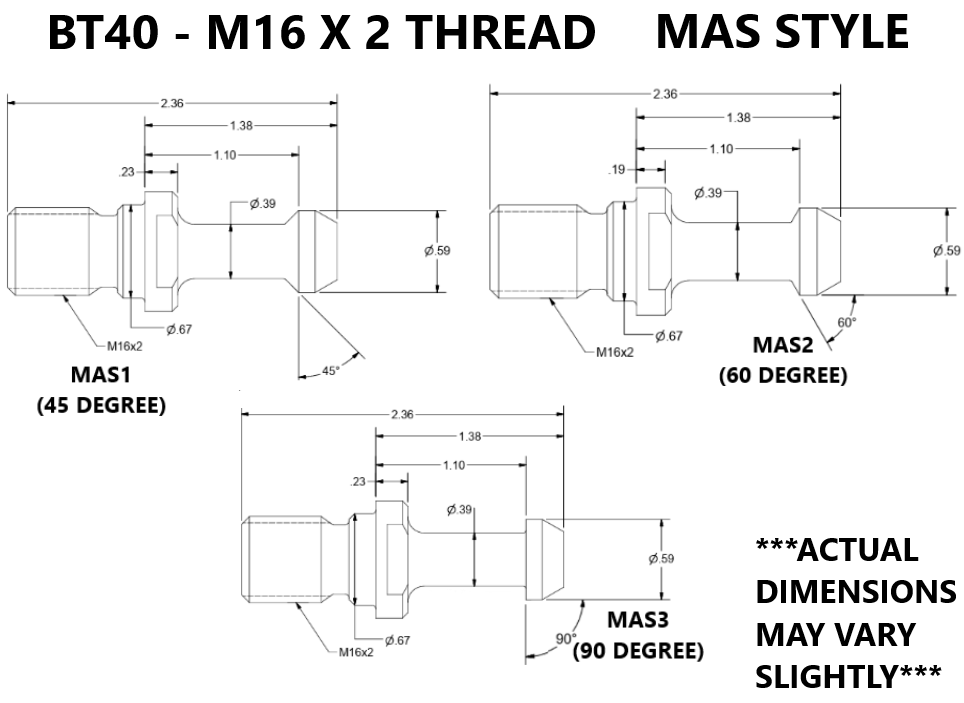

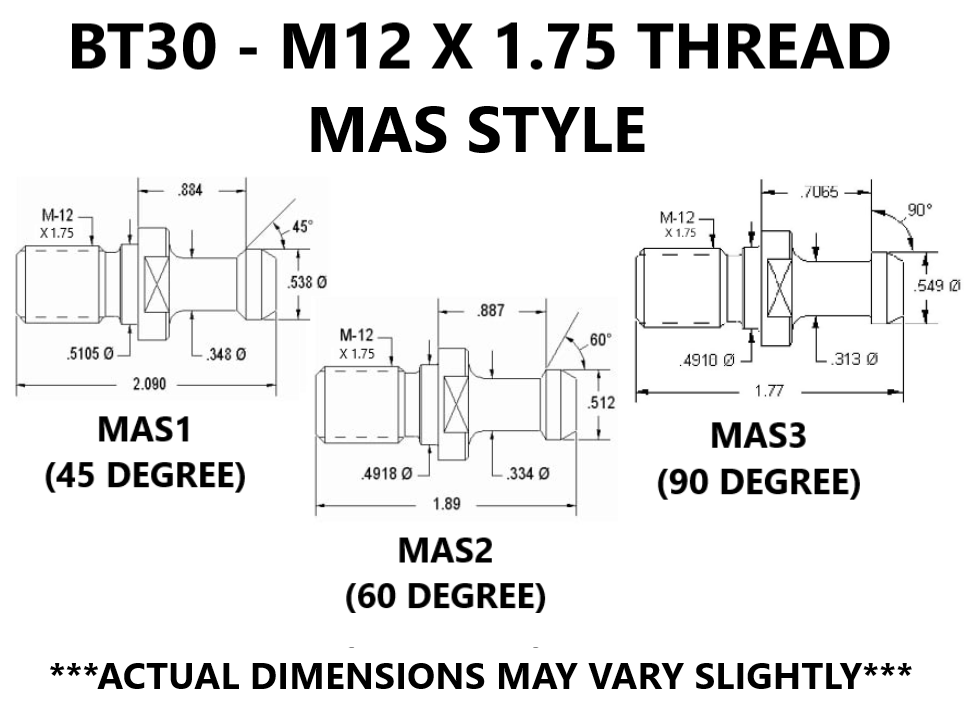

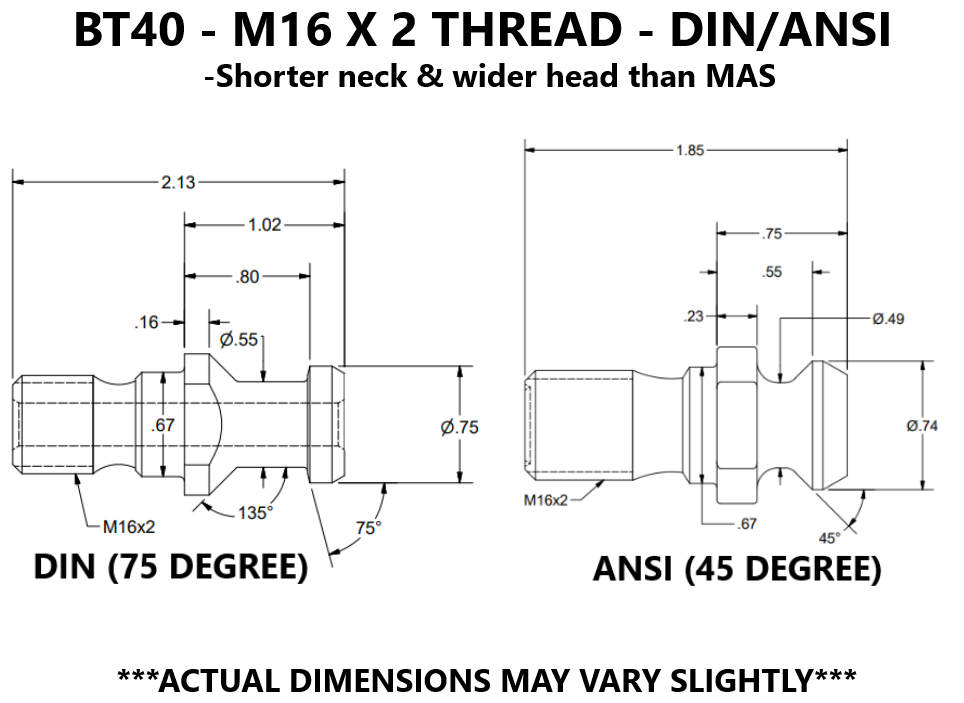

ANGLE GAGES (45, 60, 75, 90 DEGREES)

CLEAN BAGS

TICKETS

PEN

STEP 1:

VISUALLY SORT BASED ON SIZE, 50 VS 40 VS 30 TAPER. THIS IS USUALLY DONE WHEN THEY ARE REMOVED FROM THE TOOL HOLDERS, BUT ALWAYS NICE TO DOUBLE CHECK

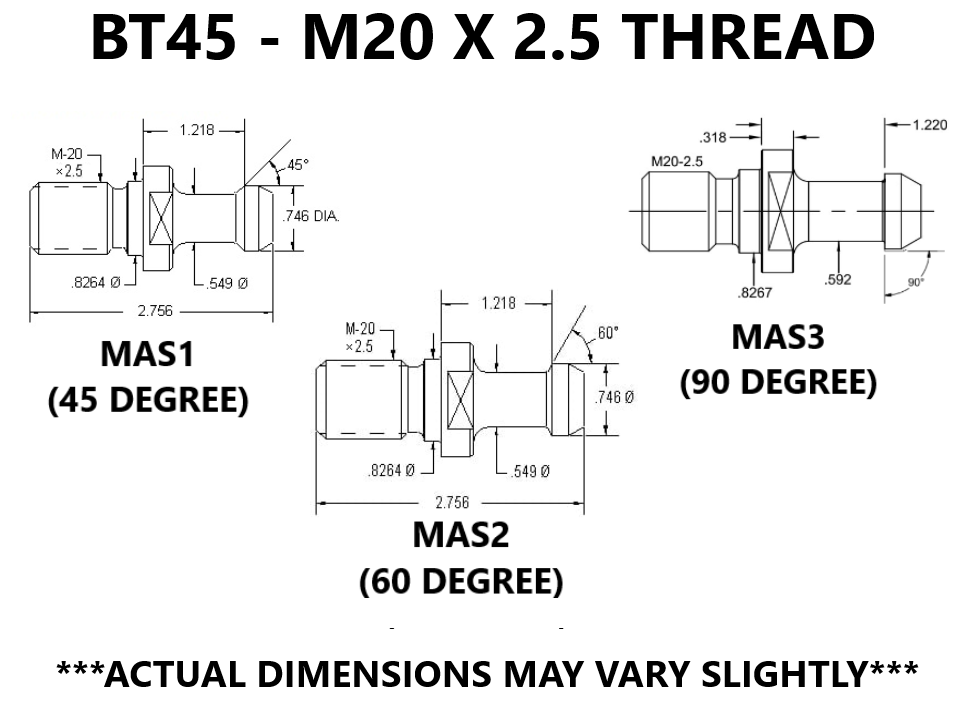

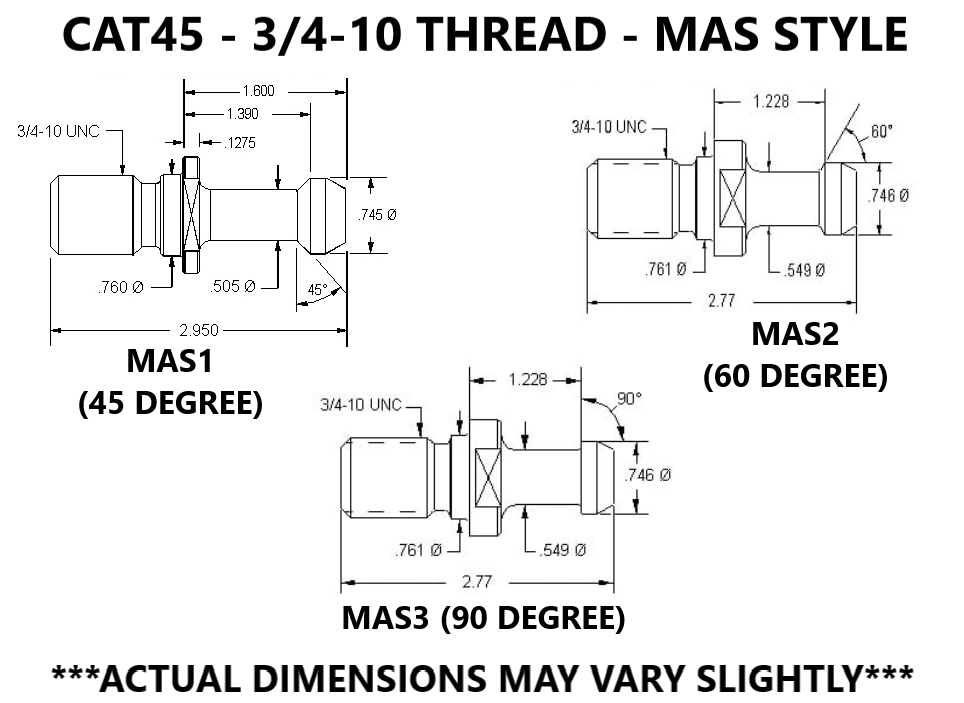

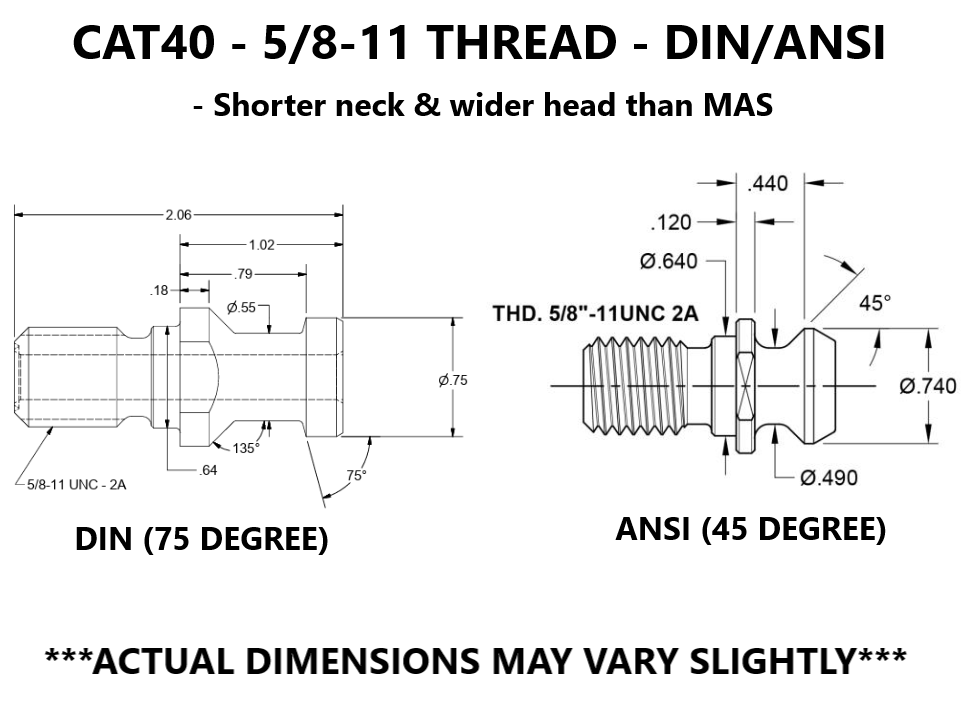

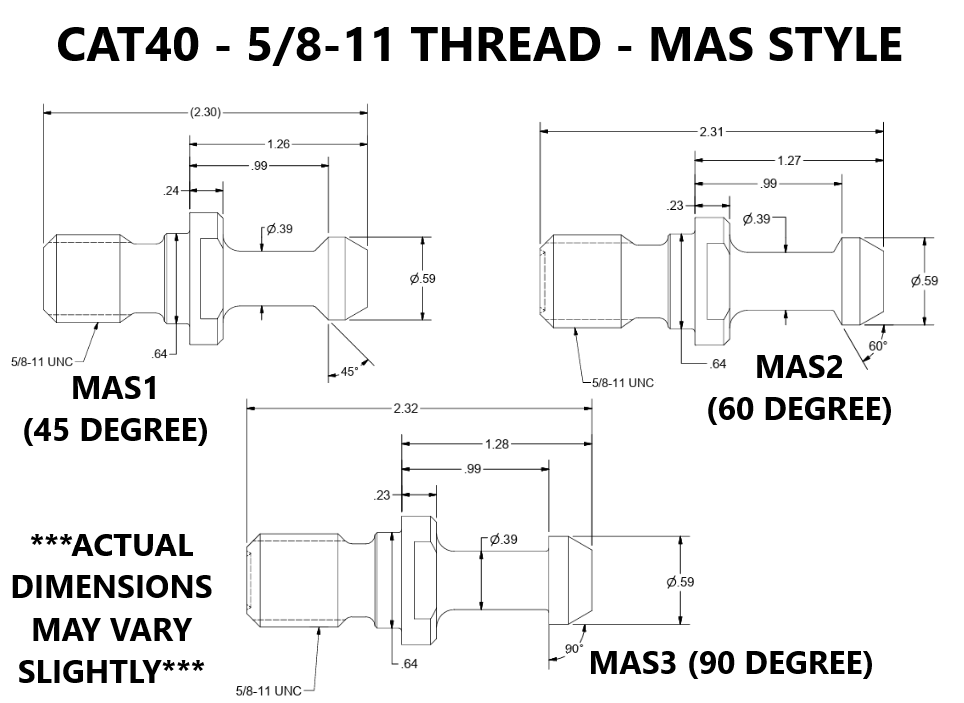

STEP 2: PRINT OUT THE CHARTS FOR THE SIZE YOU ARE MEASURING. USING AN 8 TPI GAGE (OR WHATEVER THE APPROPRIATE IMPERIAL SIZE IS FOR THE TAPER YOU ARE MEASURING, SEE PICTURES FOR REFERENCE) SORT THE RETENTION KNOBS INTO 2 LARGE PANS, "PASS" AND "FAIL".

STEP 3: SET THE FAIL PAN ASIDE, THESE ARE LIKELY METRIC AND WILL BE SORTED SECOND.

STEP 4: USING ANGLE GAGES, SORT THE "PASS" PAN INTO 5 SMALLER PANS LABELED 45 DEGREE MAS I, 60 DEGREE MAS II, 90 DEGREE MAS III, DIN ( 75 DEGREE, WIDER MAS III), & ANSI (45 DEGREE, THE SHORT ONE). REFER TO DIMENSION CHARTS IN PICTURES FOR REFERENCE.

STEP 5: GRAB 5 MORE PANS AND PULL OUT ALL THE COOLANT THRU KNOBS FROM THE PANS YOU JUST SORTED. COOLANT THRU KNOBS ARE HOLLOW IN THE CENTER ALL THE WAY THROUGH.

STEP 6: BAG THE RETENTION KNOBS IN LOTS OF 10, LABEL WITH THE FULL NAME, E.G. CAT 50 MAS II COOLANT THRU. BRING TO MATTHEWS OFFICE. LEAVE ANY REMAINING KNOBS IN THE PANS.

STEP 7: RETREIVE THE "FAIL" PAN FROM STEP 2 AND CHECK THEM WITH THE APPROPRIATE METRIC TPI GAGE FOR THE TAPER SIZE, SEE PICTURES FOR REFERENCE. REPEAT STEPS 4-6 UNTIL ALL KNOBS HAVE BEEN SORTED.