Use WD-40 and a scotch-brite pad to remove any rust or residue from the face mill, being careful not to remove any labeling while doing so. Wipe down with a dry rag to remove any excess WD-40 before picturing.

Click here for info on how to upload pictures

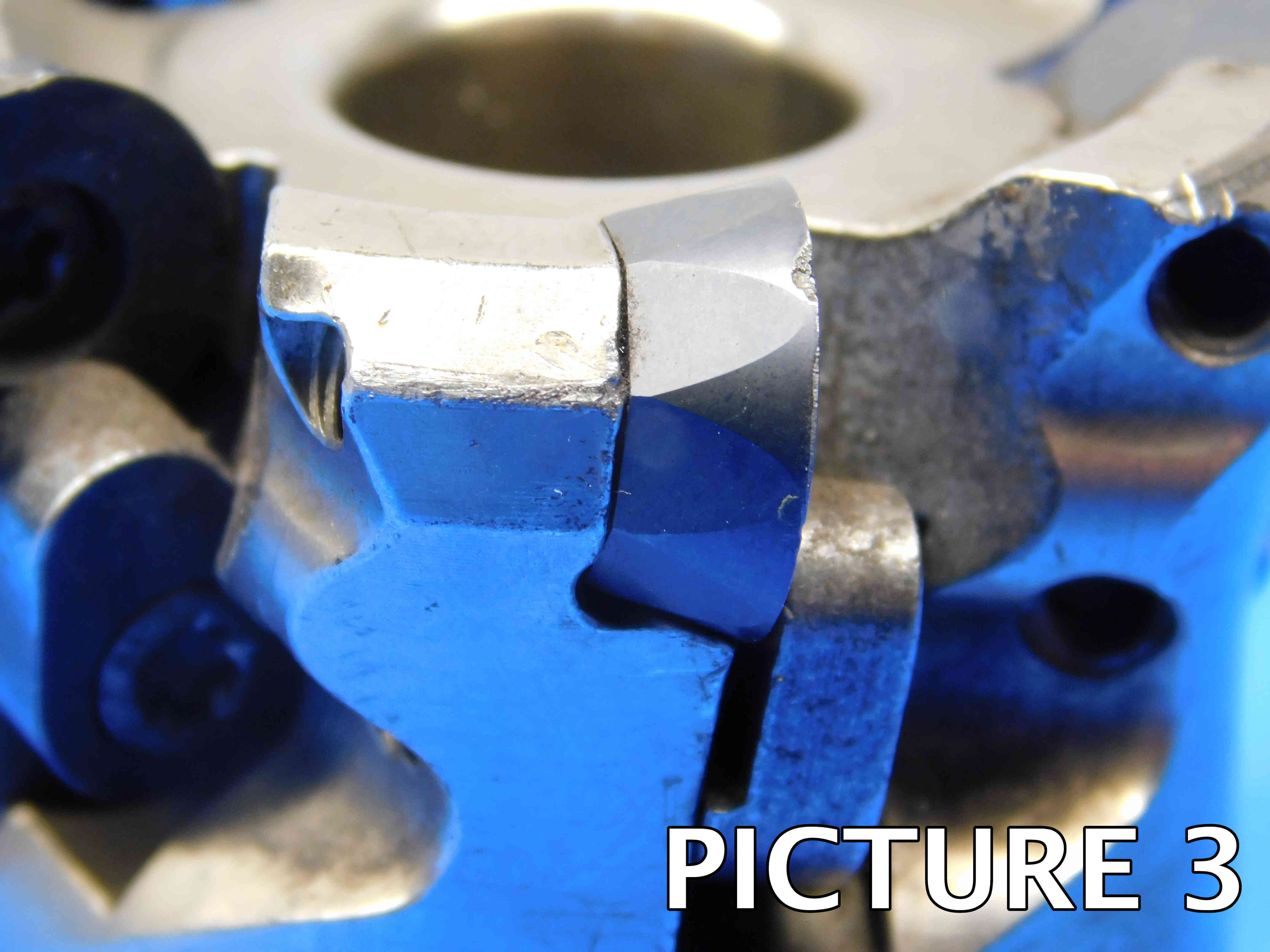

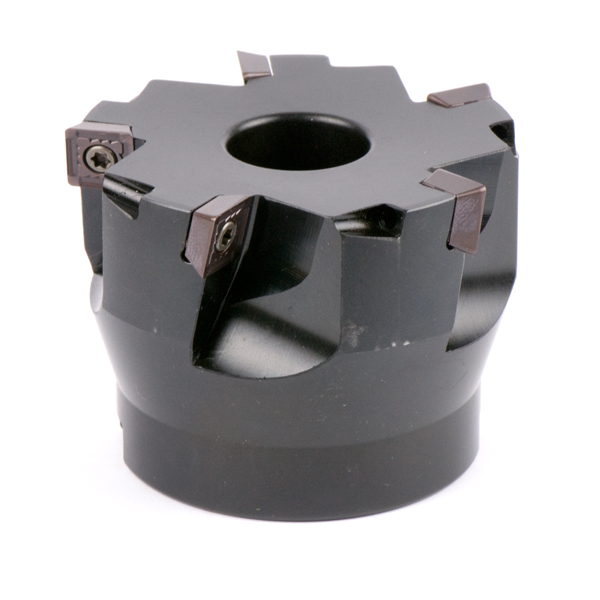

1st Picture: A side view of the face mill, with a tape measure at the bottom of the frame to provide size reference.

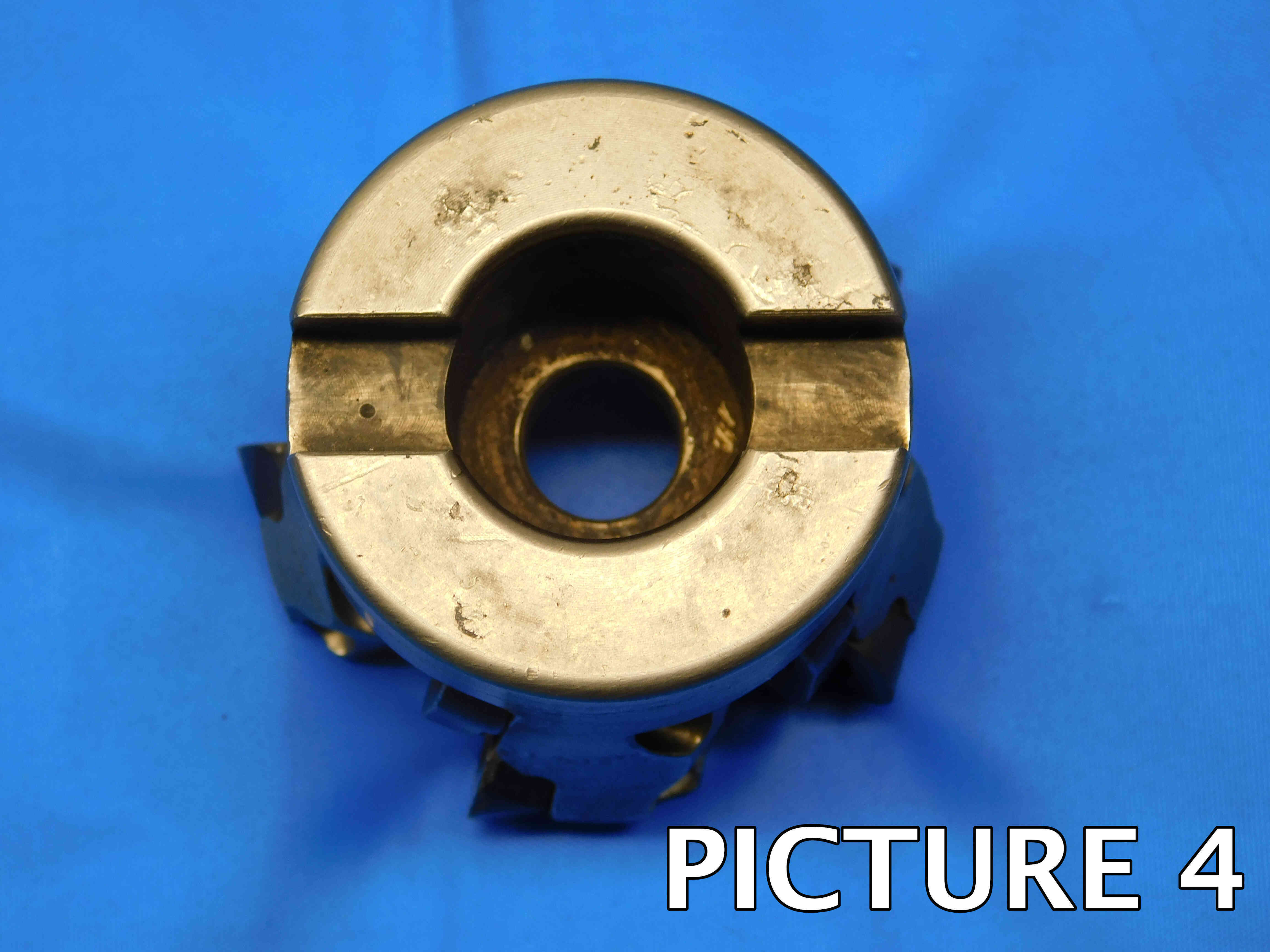

2nd Picture: A top-down view of the face mill, again with a tape measure for size reference. If there is labeling on the face, be sure to orient the face mill so that the labeling is readable (i.e., right-side up). Any packaging should also be included in this picture.

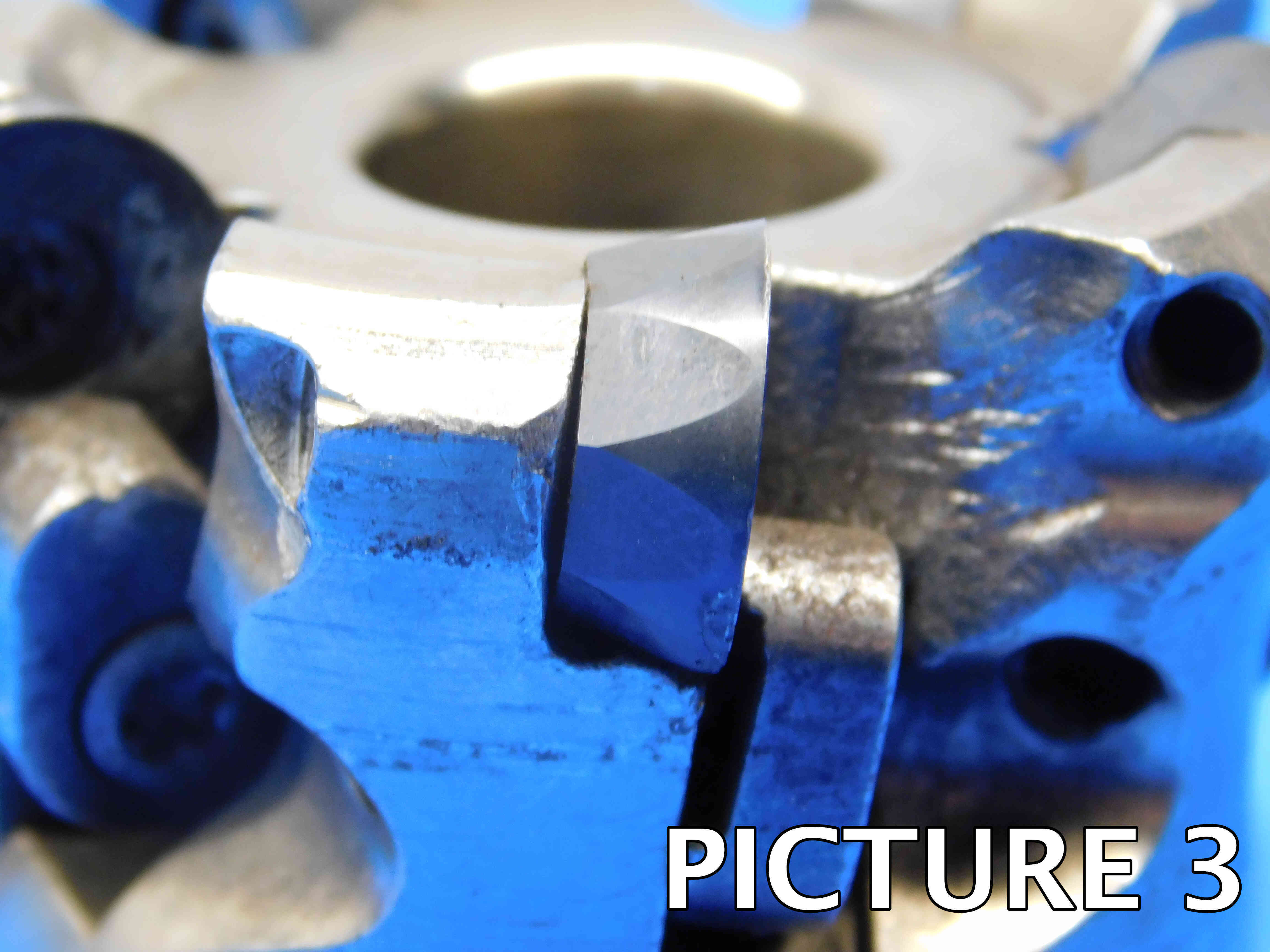

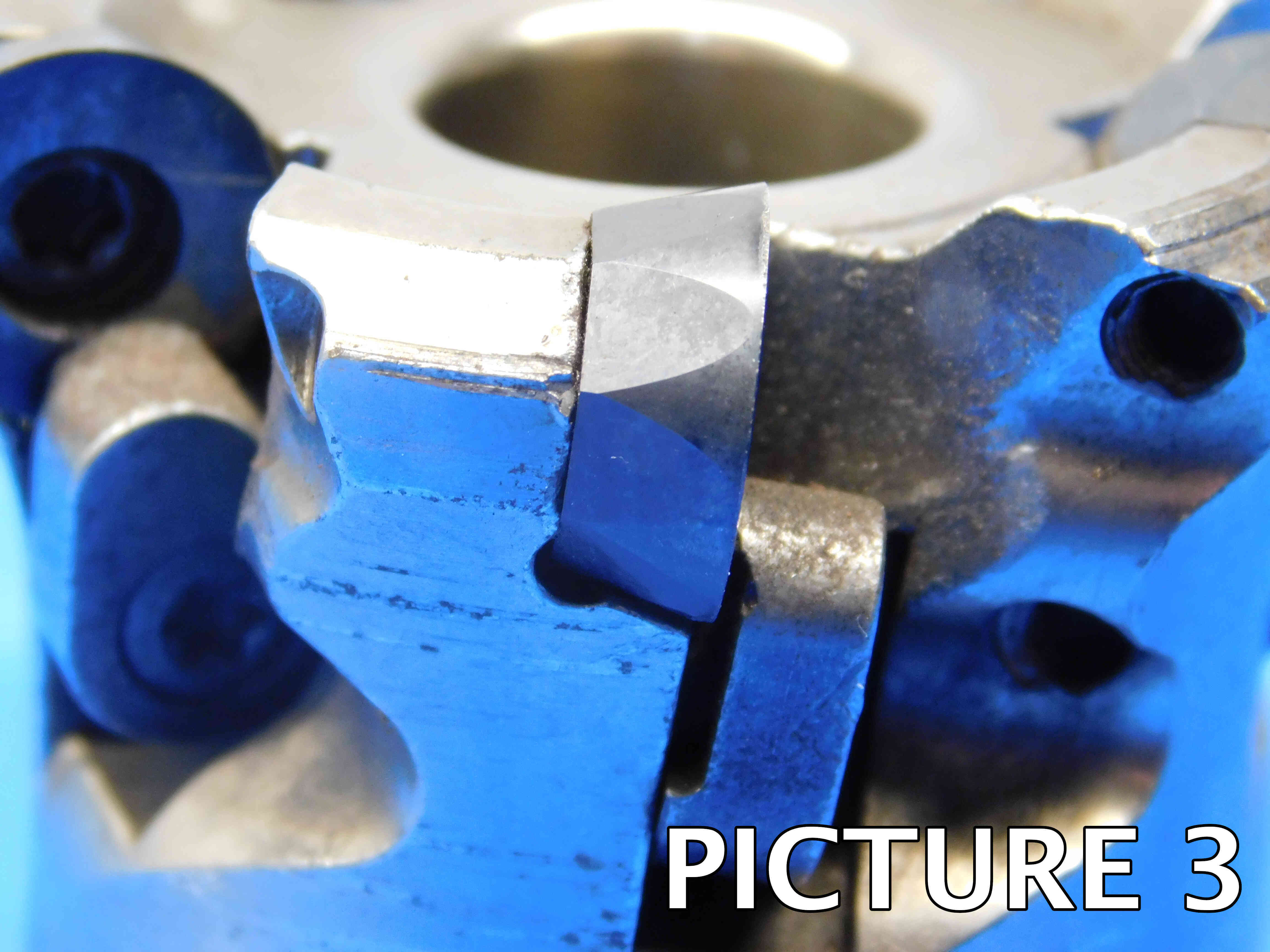

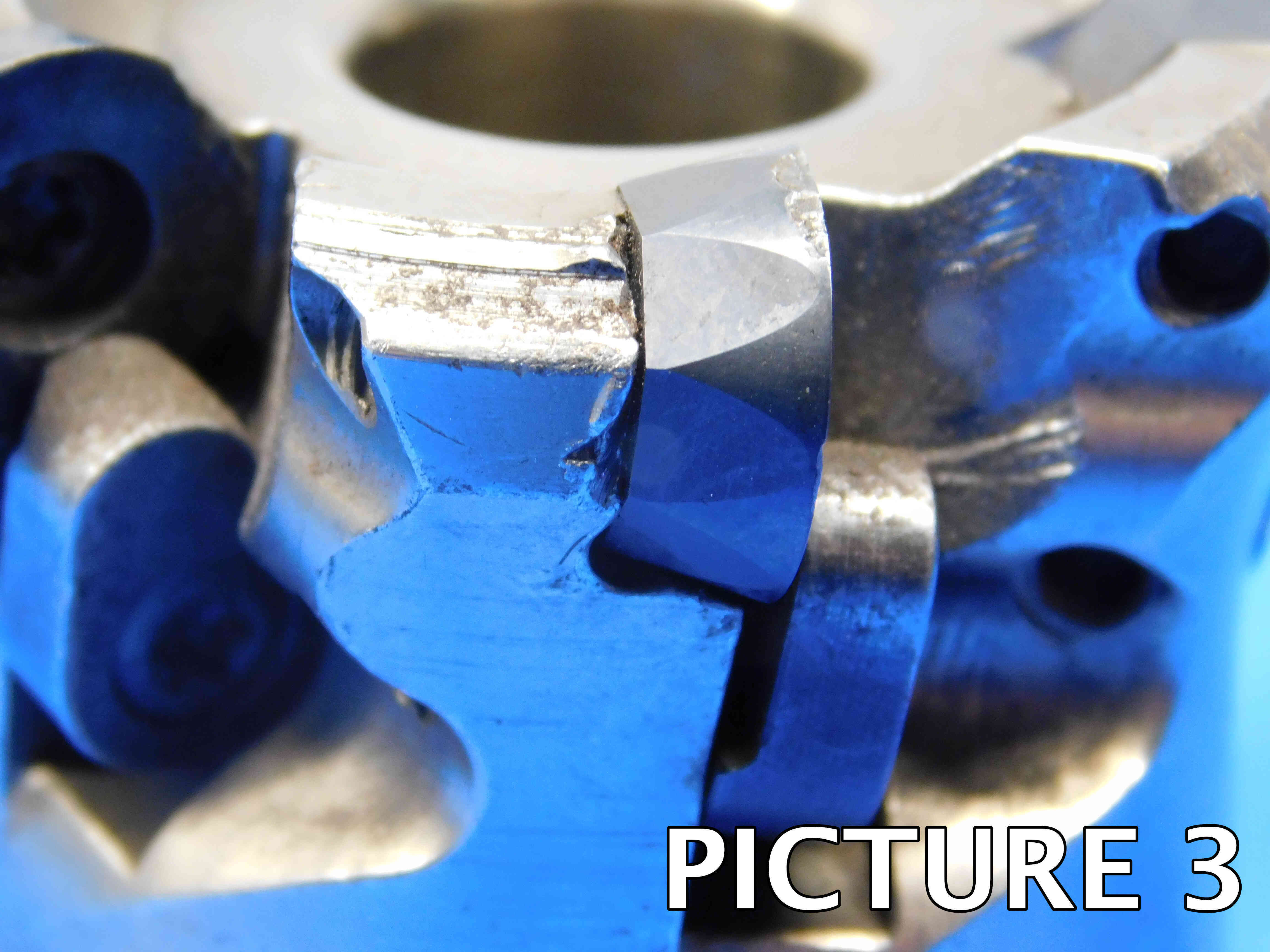

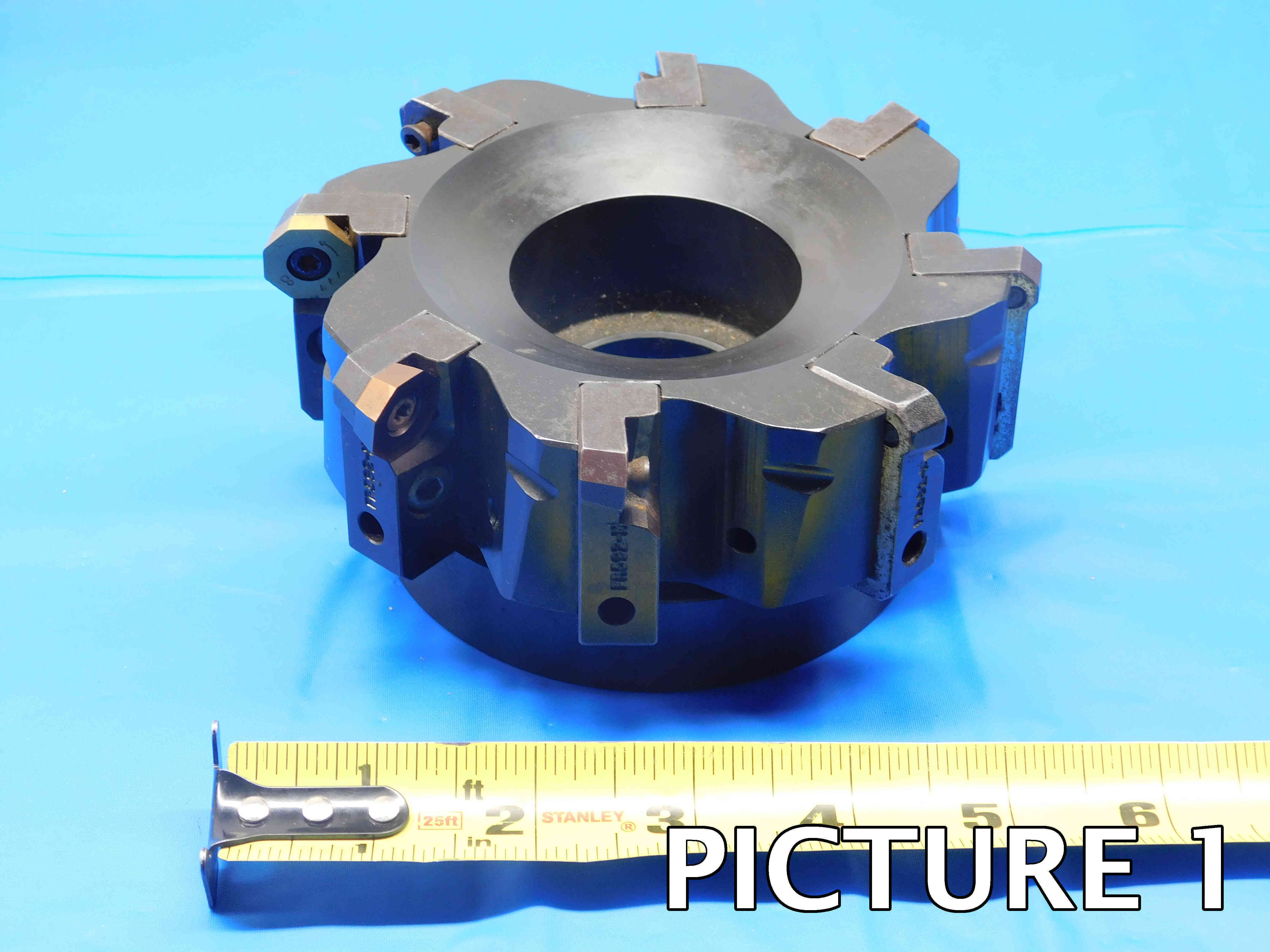

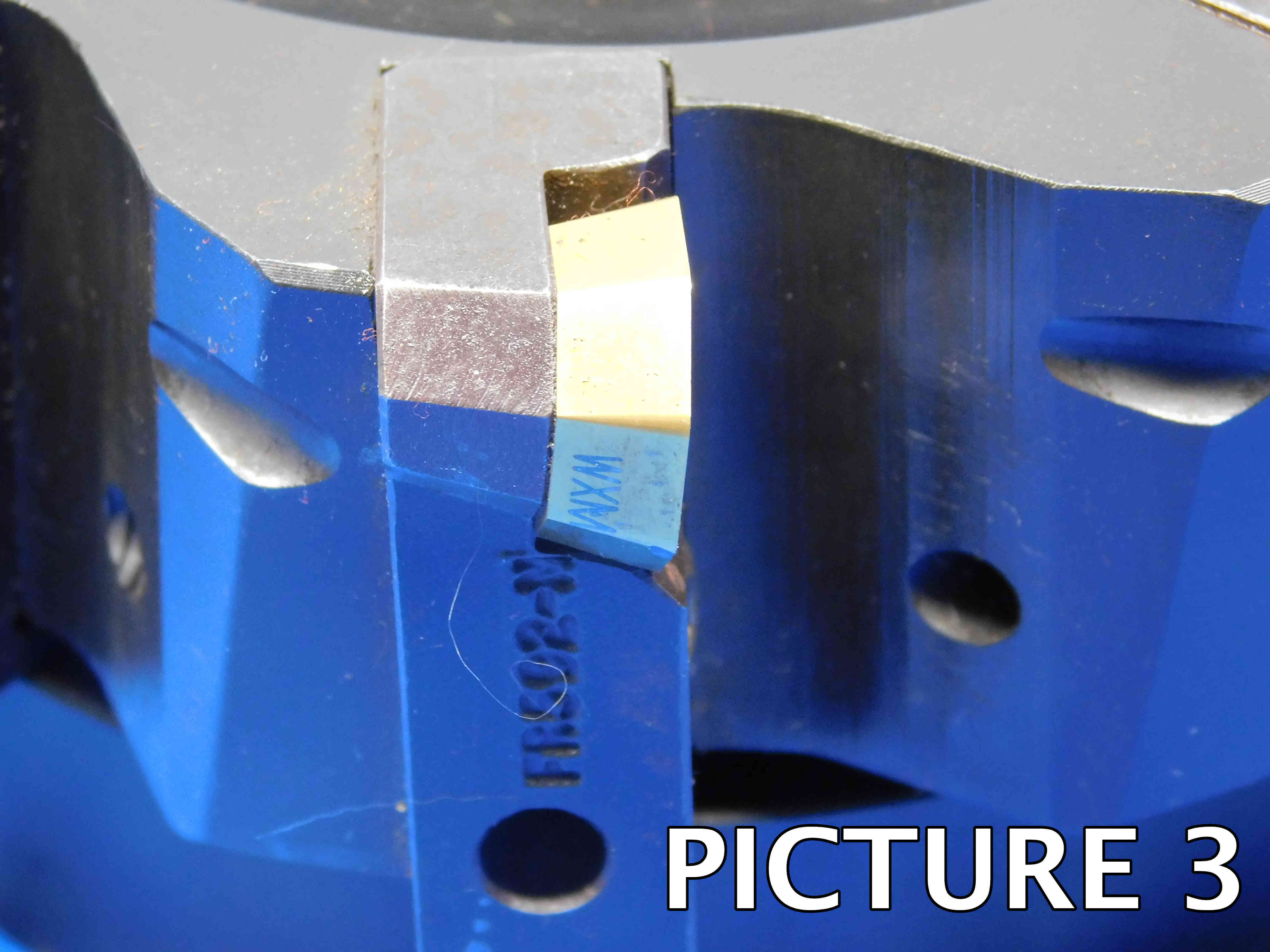

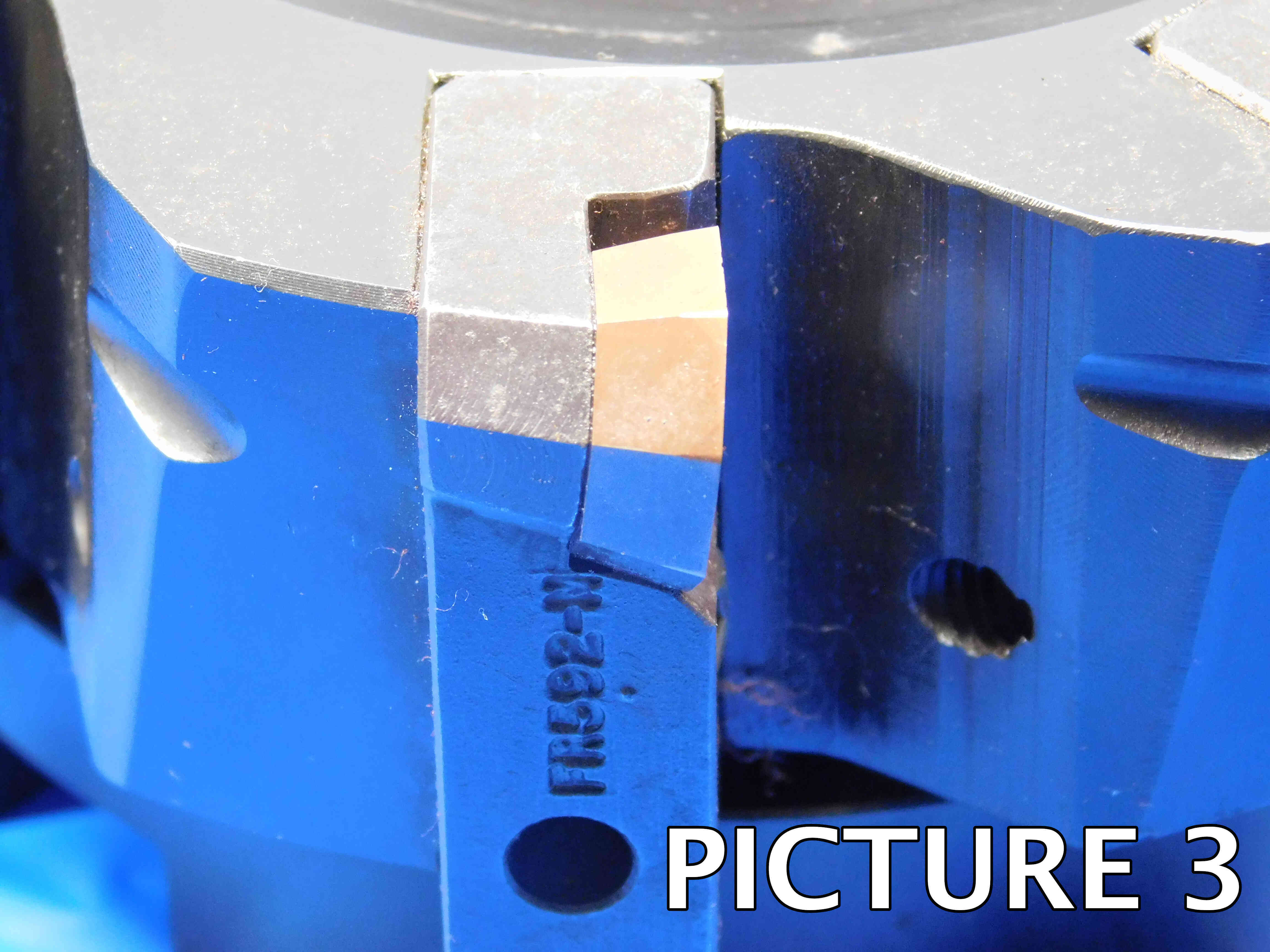

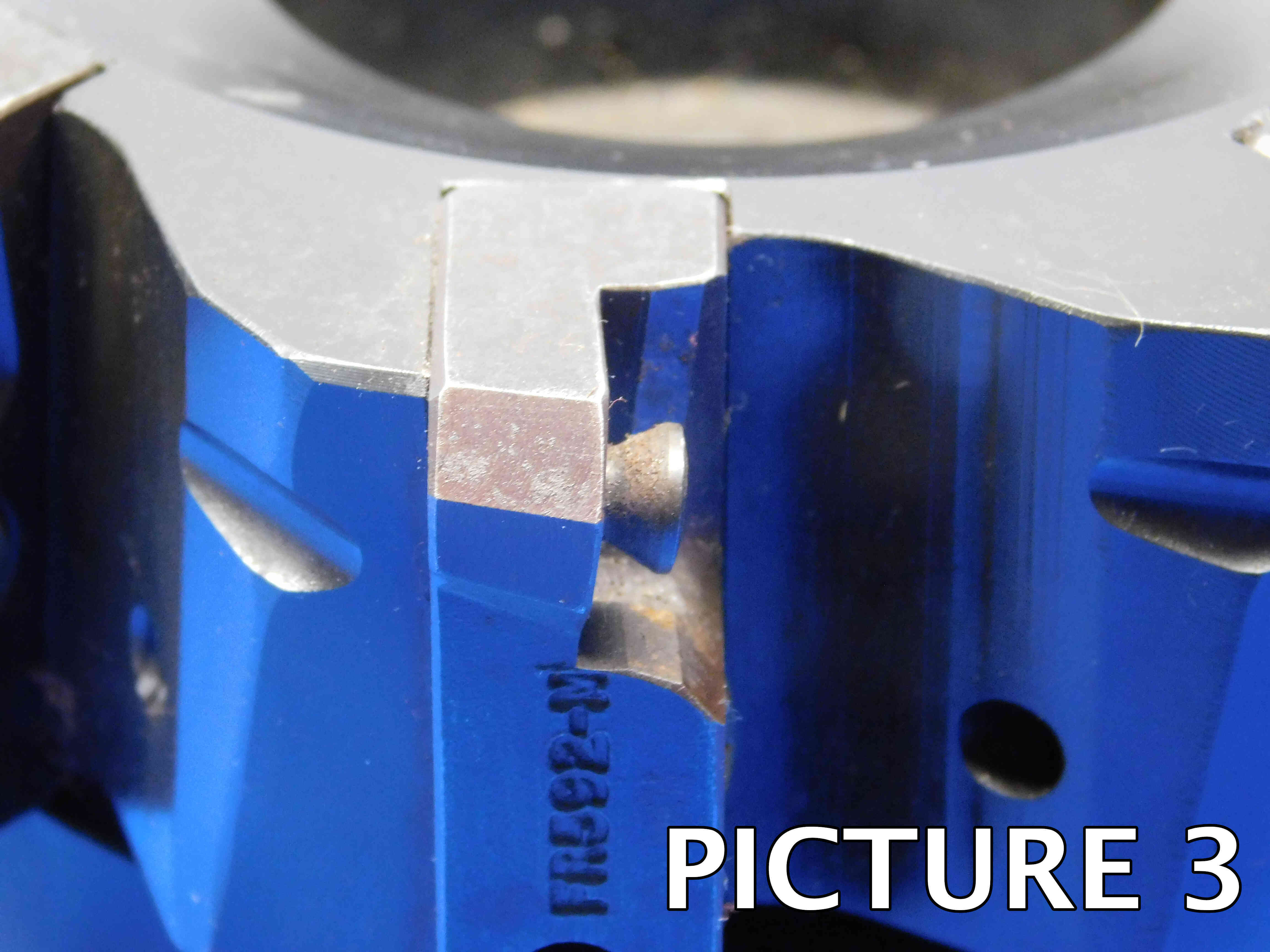

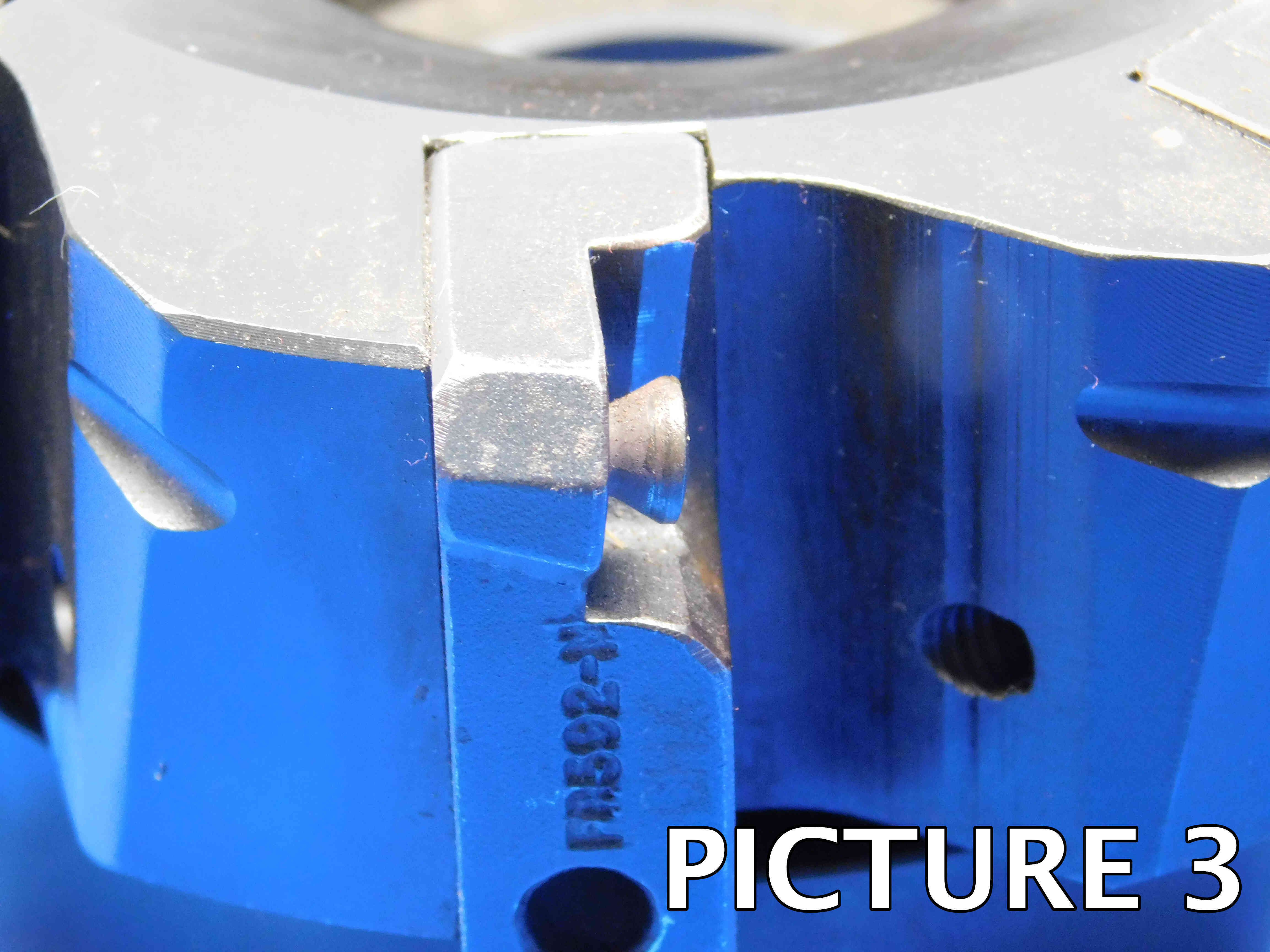

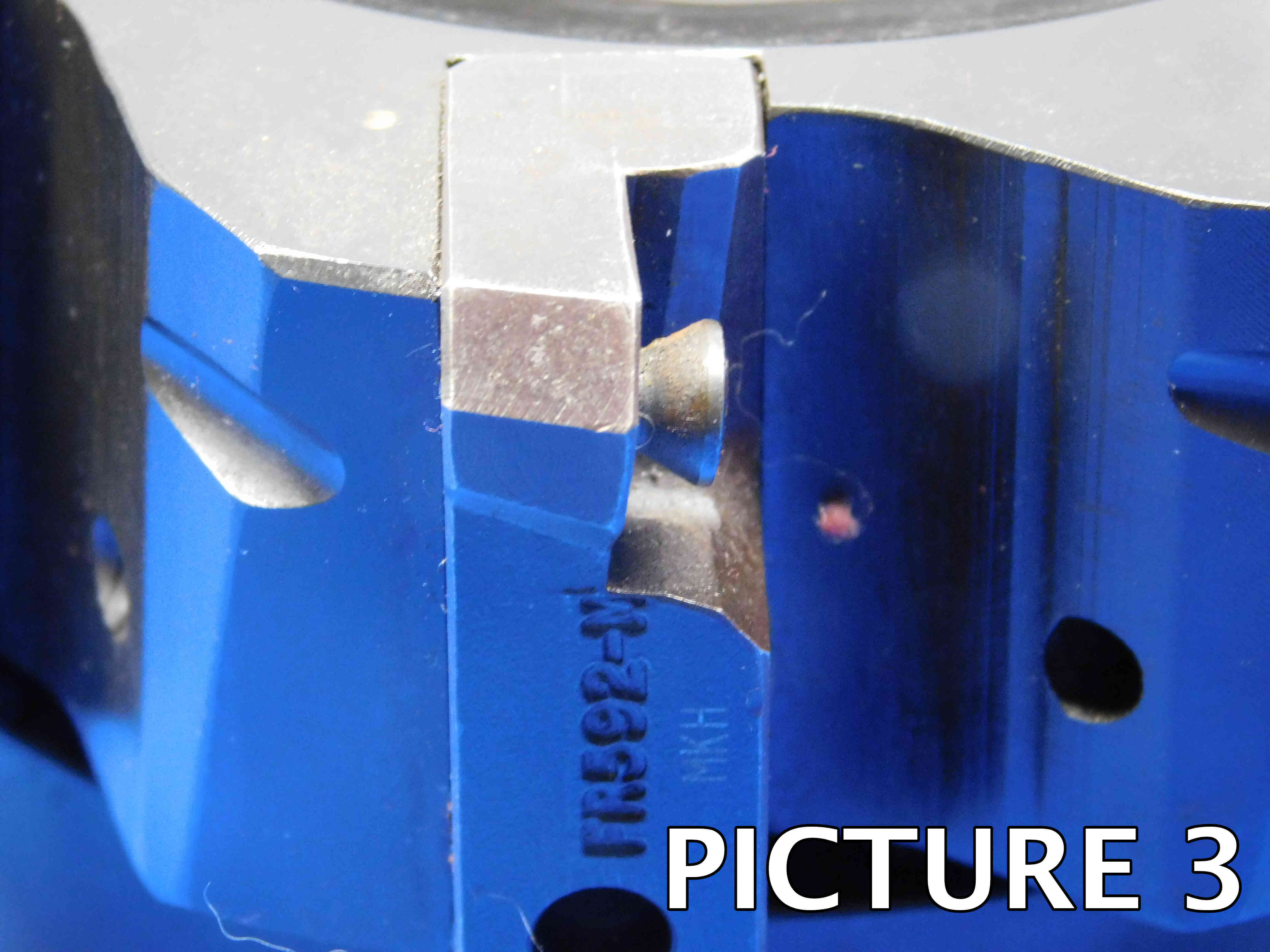

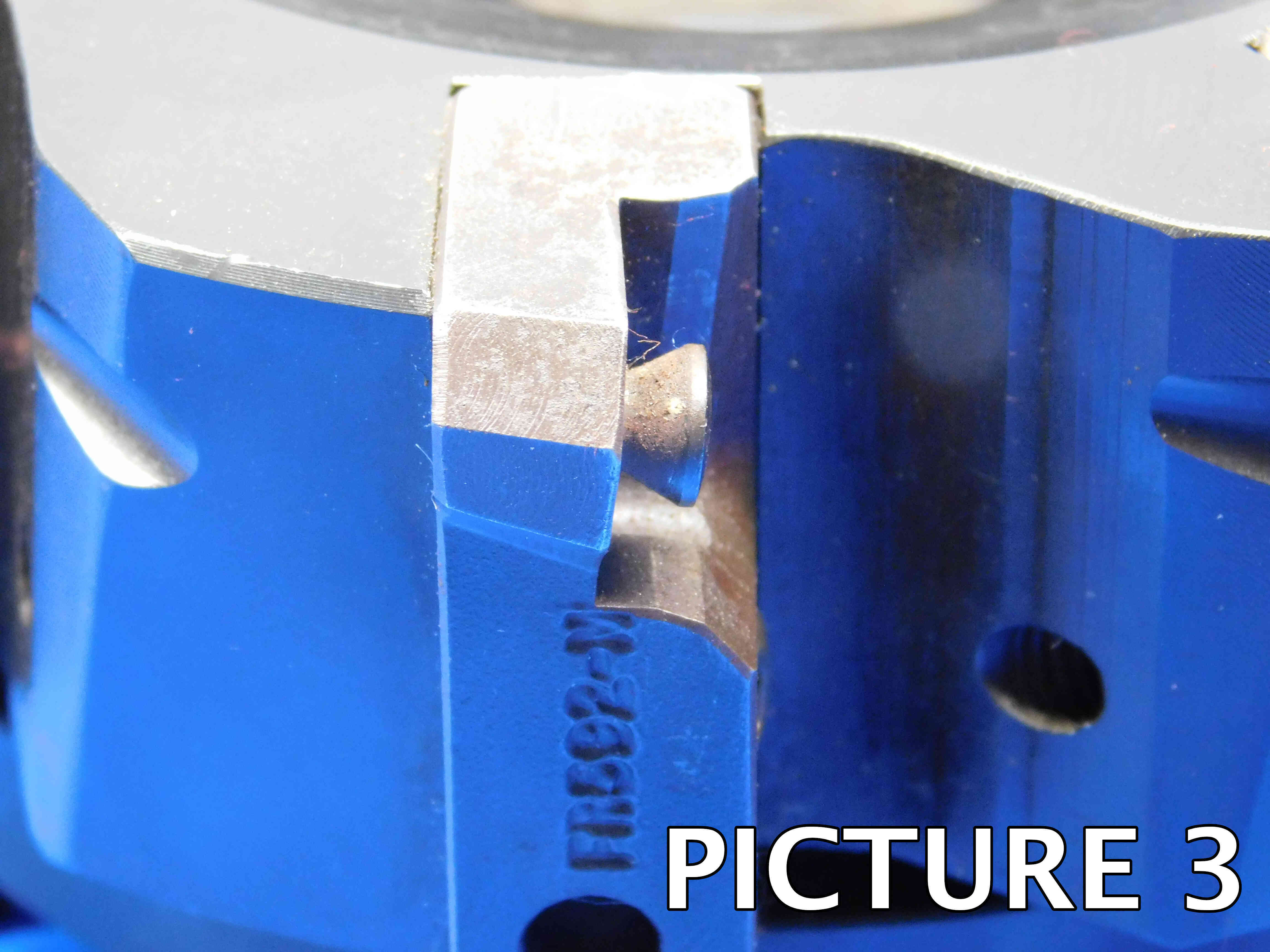

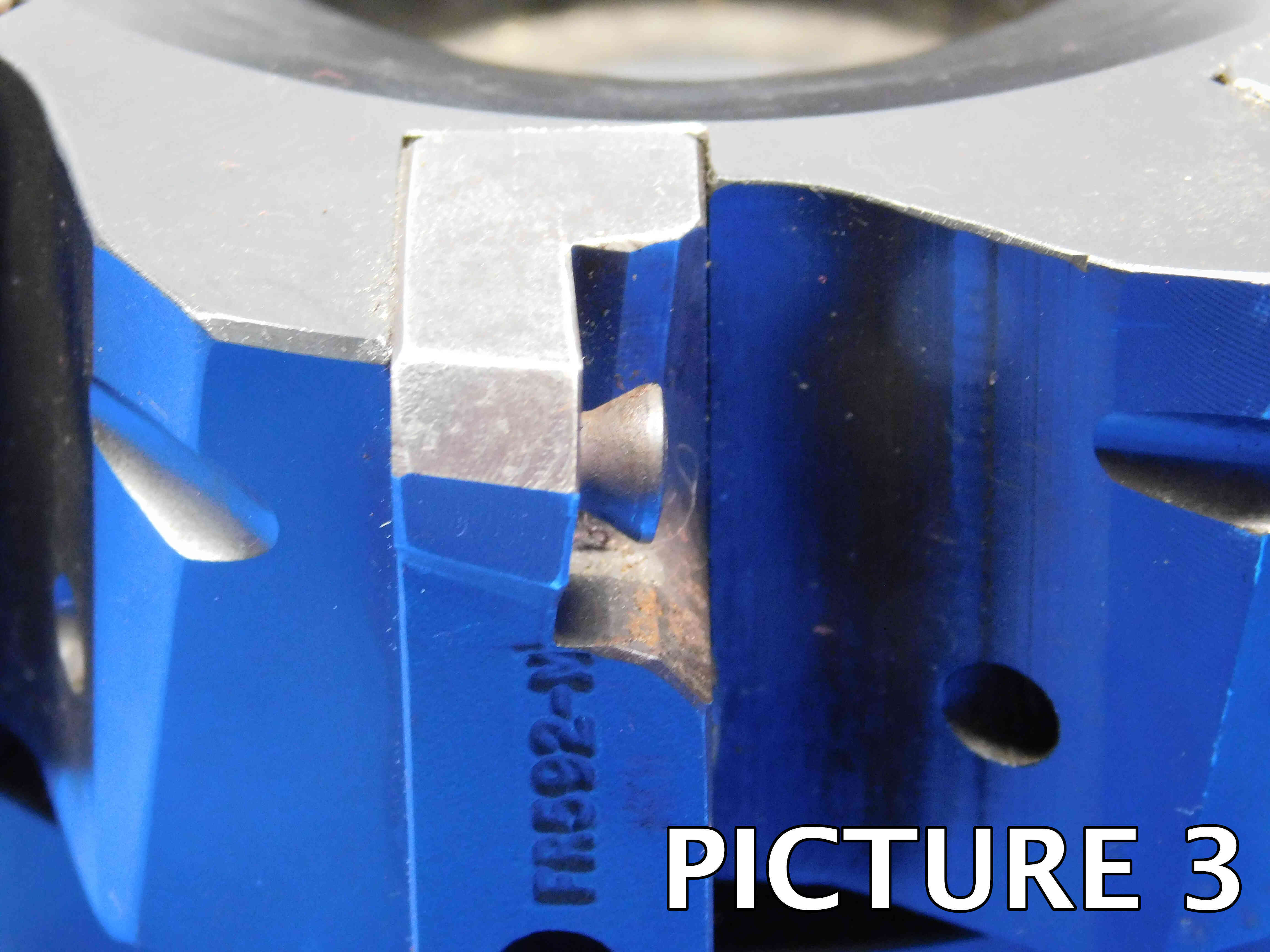

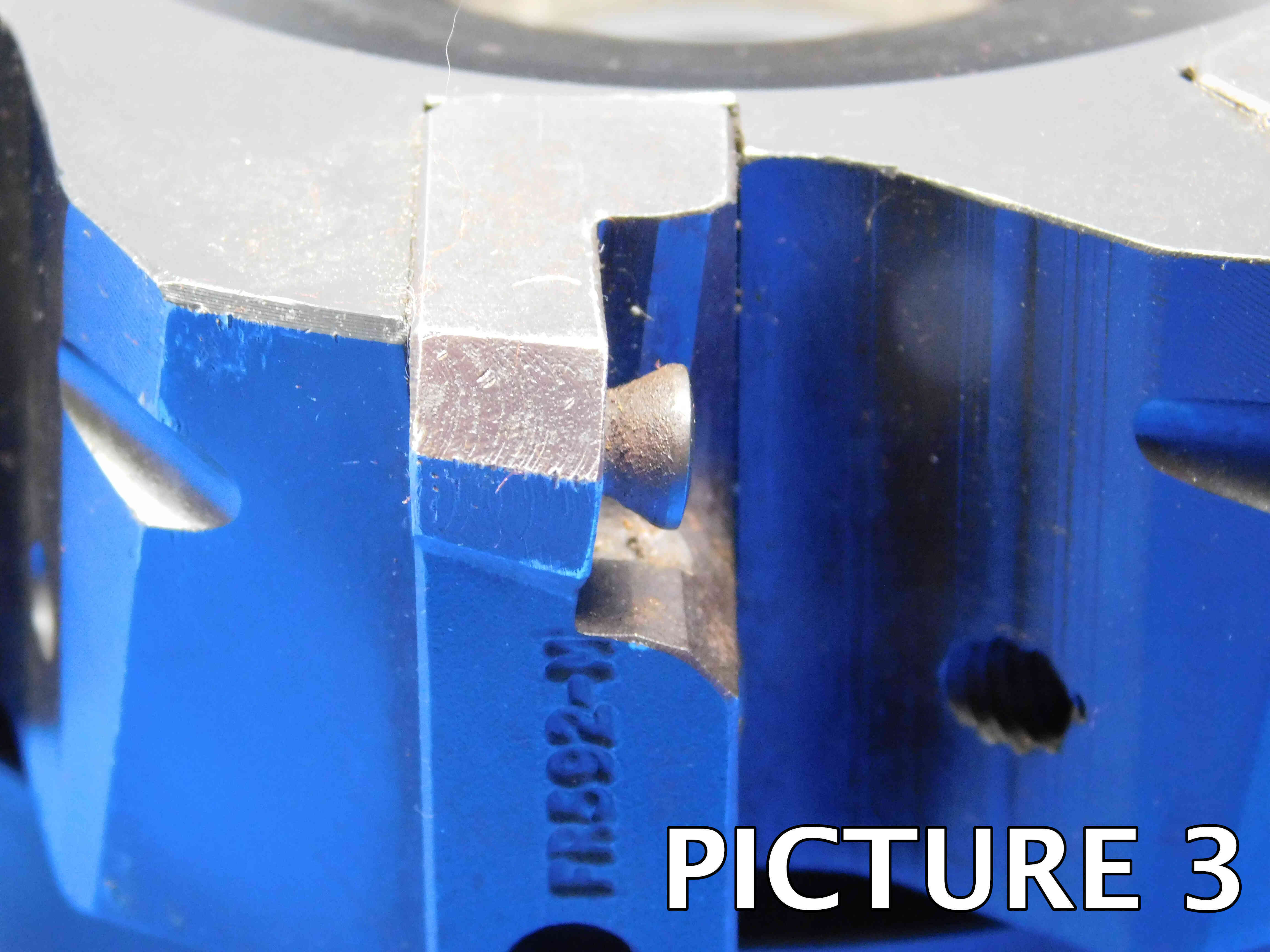

"3rd" Pictures: A side view of each insert pocket. If there are especially large number of pockets (like more than 8) you might not be able to include a picture of every pocket due to upload limitations - in this case, contact your trainer to determine which pockets to prioritize.

These pictures must be present on all used face mills and must match the examples shown below! The insert pockets are the most important part of the tool and the condition must be 100% clear in the pictures! ***If a face mill is NEW, you may skip these pictures as there will be no wear / damage that needs to be shown***

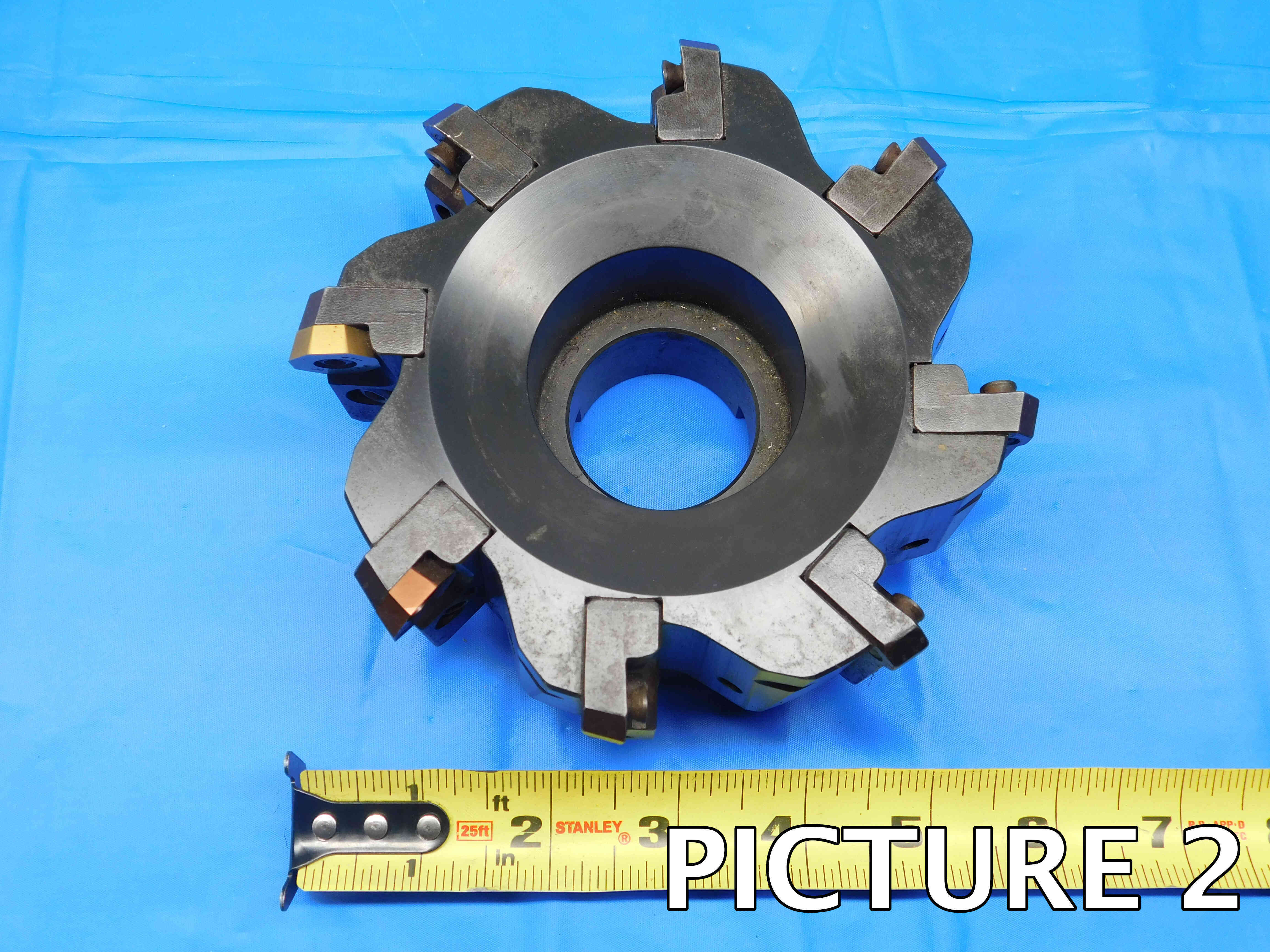

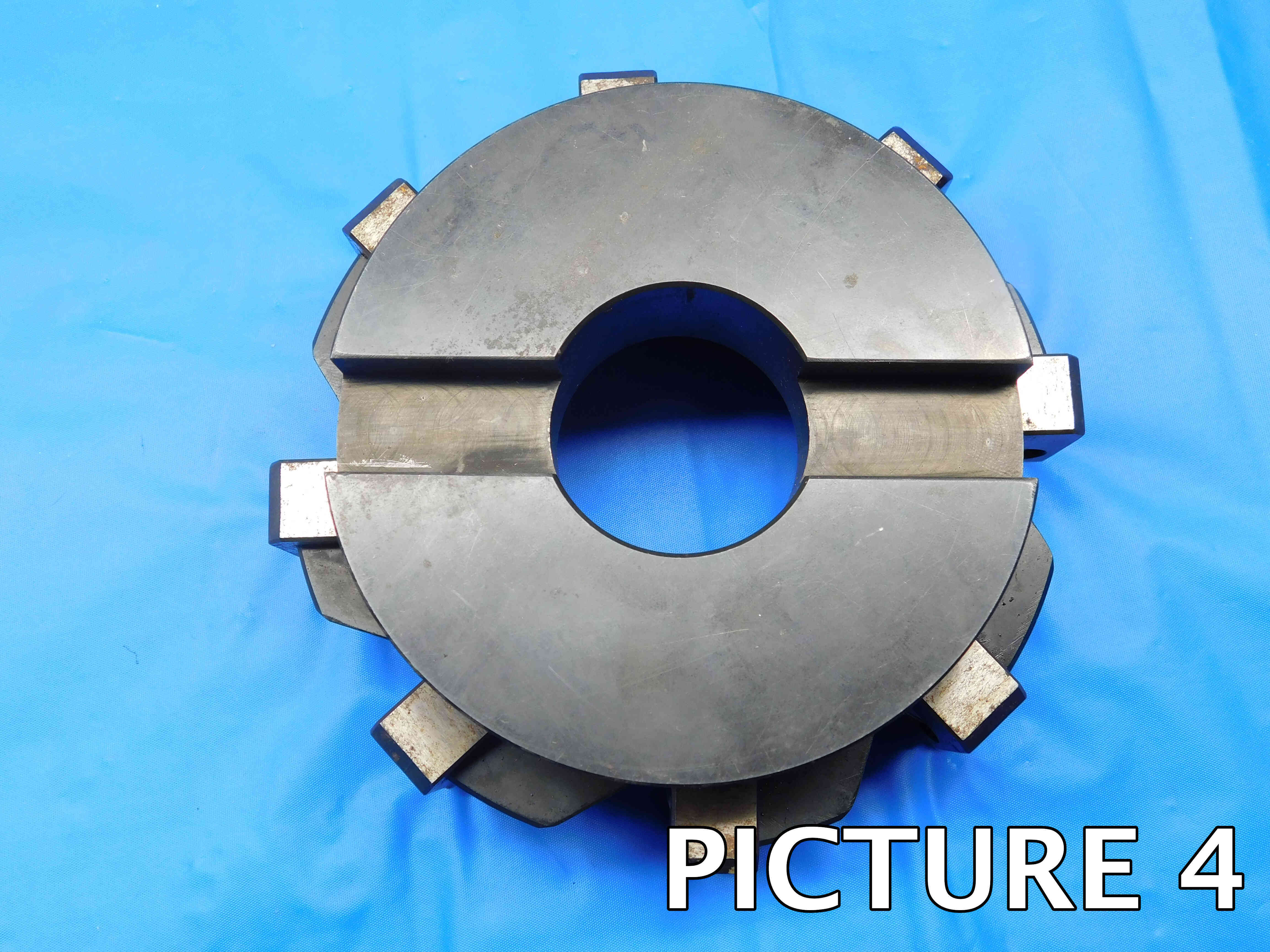

"4th" Picture: A picture of the bottom side of the face mill, clearly showing the pilot hole and keyways.

"5th" Picture: A close up shot of the labeling. Depending on where the labeling is located, this may require more than one picture. If no labeling is present, or if it is too faded to show up in a picture, skip this picture.

Additional Pictures: Any damage or modifications, especially to the insert pockets, must be clearly pictured. If any of the insert pockets are missing their screws, it MUST be pictured as well as mentioned in the "Special Condition" section. Use a pen to point to the damaged area. Refer to the second set of pictures below for an example. If you think you may require additional pictures for any other reason, contact your trainer to verify if they are necessary.

Please refer to the examples below:

The brand will frequently be labeled on the face mill. If the brand is not labeled, click the "Unlabeled" button to the right of the brand cell. Make sure this cell is not left blank, or the listing will not upload properly. Note: Items are often labeled with the country of origin (USA, China, Japan, Poland, etc). This should NOT be entered as the brand, and furthermore should not be included in the listing at all EXCEPT for USA which can be used as a filler.

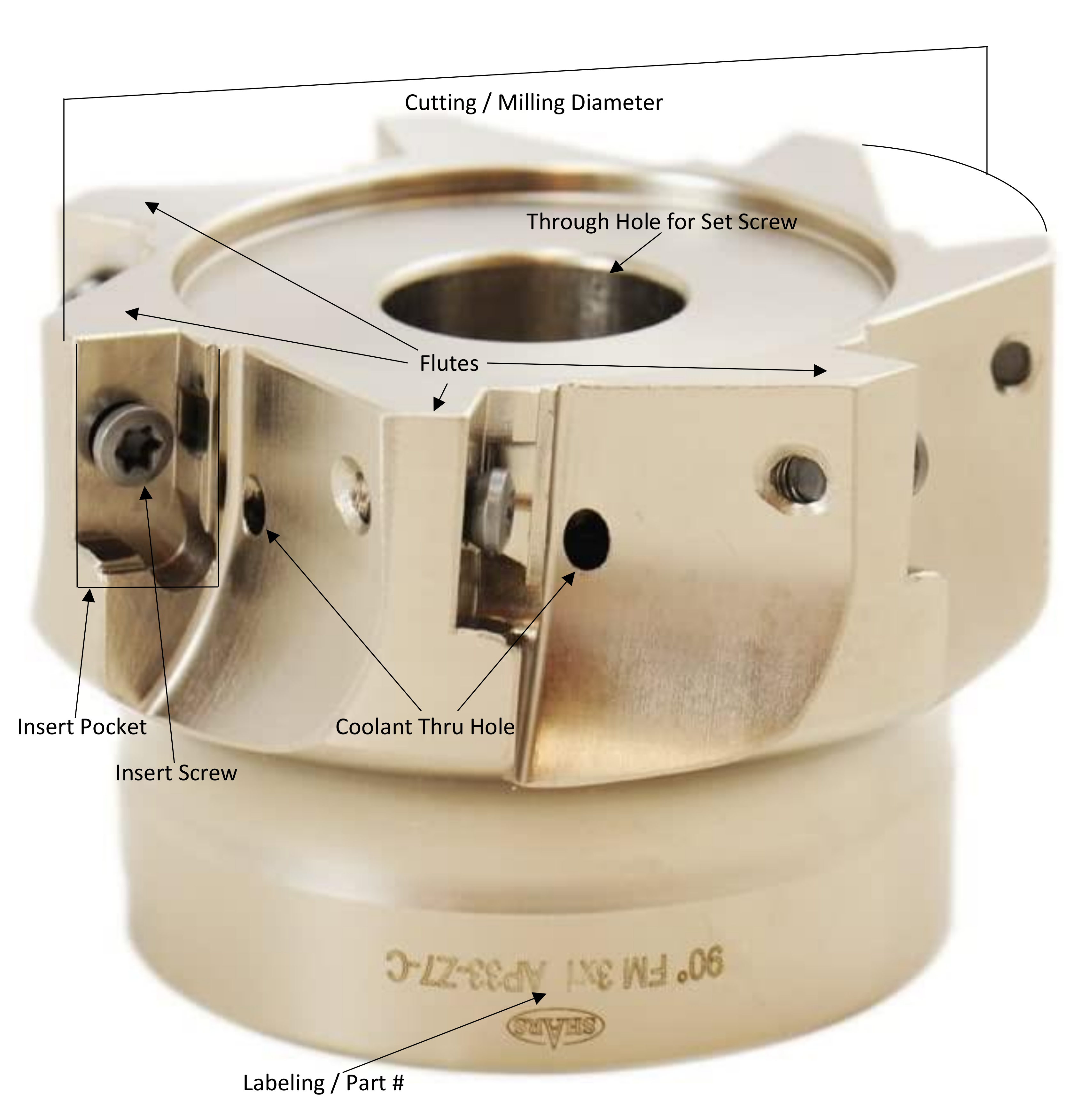

Face mills may be designed to be coolant thru / fed in order to protect the tool & workpiece from overheating. This can be identified by unthreaded holes typically near the insert pocket that will connect to a central hole in the tool. Threaded holes that are used by the insert screws ARE NOT coolant thru holes. Refer to the diagram at the top of this page for an example of what these coolant holes will look like.

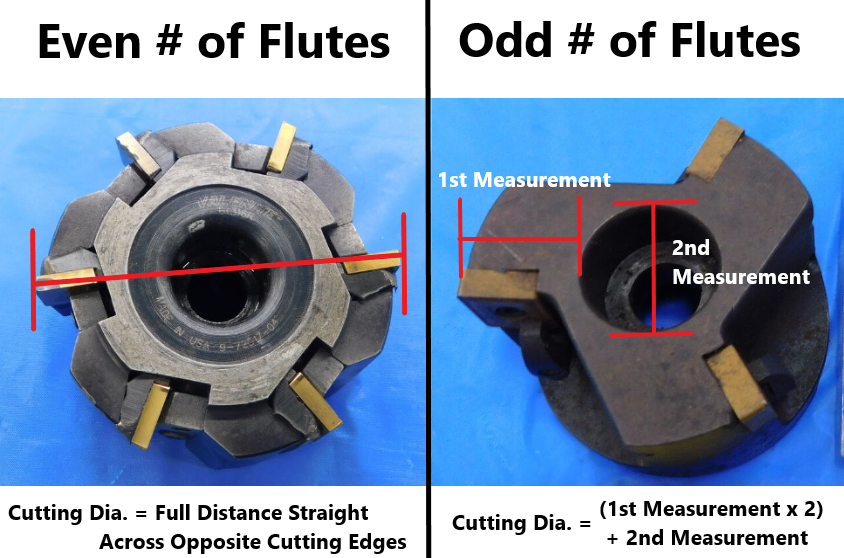

The Cutting / Milling Diameter is often labeled, but can also be measured from the end of the cutting surface of insert (the furthest & highest point on the insert from the pilot or set screw hole) to the opposite end. If the face mill is 90 degrees (meaning the insert is flat on top and sits flush with the top of the face mill body), this is simply the furthest two points on the inserts, but if it is a 45 or 60 degree face mill, or a shape that is not flat all the way across the top such as an octagon, you will need to make sure you are measuring from the highest point of the insert, which may not necessarily be the outer edge.

If there are an even number of flutes and there are inserts present this can be measured with calipers. If there are an odd number of flutes and there is no hint given from the labeling, you can figure out the diameter via the following method:

1. Measure from the very end of the insert (or insert pocket) to the outer edge of the "Through Hole for Set Screw", then multiply this number by 2

2. Measure the inner diameter of the "Through Hole for Set Screw" and add this number to the number from step 1. The total will be the cutting diameter of the face mill (you can round up or down if you are very close to a round number, for example 3.998 -> 4")

Refer to the picture above for more info.

Note: When entering a whole-number inch size, always include the " sign. The " sign should not be included for any size including a fraction or decimal. So, for example: If a face mill's cutting diameter is exactly one inch, it should be entered as 1" and not just 1. If the cutting diameter is one and a half inches, it should be entered as 1 1/2 or 1.5 and not 1 1/2" or 1.5".

Metric size measurements should be entered with a lowercase "mm" (ex.: 16mm, 40mm).

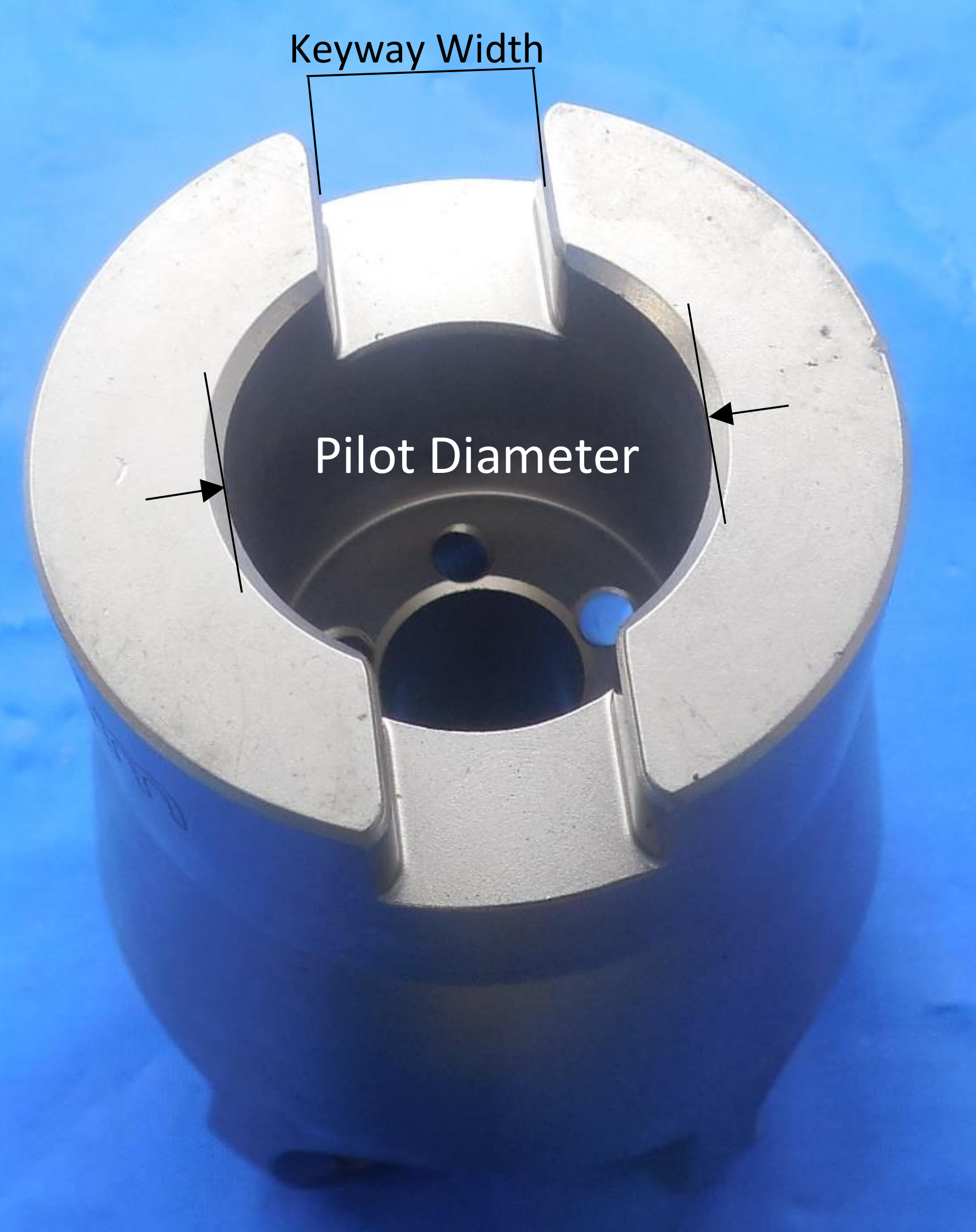

Pilot Diameter & Key Width / Shank

Face Mills will either be held in a tool holder by a pilot & key, or a shank similar to those seen on end mills. The most common is the pilot & key, which can be measured by a pair of calipers and are typically very standard sizes. The straight shank seen in the 2nd picture is less common, and there can also be an R8 shank which looks very similar to the straight shank, but with a tapered portion close to the face mill.

If the pilot diameter & key cannot be measured because it cannot be removed from a shank / arbor, and using the labeling / part # for research doesn't give you the information, this may be left blank.

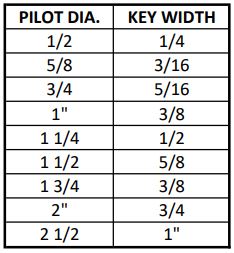

There are standard pilot / key size combinations which a large majority of face mills will adhere to. Refer to the chart below for more information:

The number of inserts (or insert pockets) can simply be counted, and can be as few as three or as many as ten or more. The more flutes a mill has, the stronger the tool is at the expense of less chip clearance.

When inspecting a face mill, be sure to look for damage to the insert pockets, as this can greatly affect the tool's use. Any damage to the pockets must always be clearly pictured and described in the listing's "Special Condition" description.

Typically inserts are sold separately from face mills, so provide as much information as possible in the "Inserts Held" section. The insert part #'s or specifications can often be found by researching the face mill's part numbers. Some face mills will use common turning or milling insert types such as SPLT, RNMA, or APKT, which may be able to be identified based on their shape & dimensions, but others will use more specialized inserts. You may also find more information on inserts here: General Insert Information & Identifying Inserts

The part number should be entered exactly as it appears on the face mill. There may be additional information in the labeling which can include things like Max RPM and even part numbers for the insert screws - if so, enter just the main part number in this cell and include the rest of the labeled information in the "Additional Specifications" section.

Of the three pictures seen above, the first is a round insert face mill, the second is a 90 degree insert face mill, and the third is a 45 degree insert face mill. These are the most common options, but there are also face mills with more specific lead angles such as 60 degree or 82 degree. Because of this, the lead angle should only be noted in the listing if you are 100% sure it is correct - either because the labeling leads you to the answer, or because it is a square or diamond insert that is at a clear 90 or 45 degree angle.

The "Filler" section is used to add other relevant information to the title which is not covered by the other sections. Fillers can be a good way to increase a listing's visibility - we always want to include as much information as possible that we think a customer might be searching for in order to make sure that our listing is coming up in their search results.

There is not necessarily one right answer when it comes to fillers, and often it will be up to you to decide what should and should not be added as filler. Face mills generally do not require much filler, but some possible fillers include:

-Secondary labeling or branding / product names

-"USA" or "USA Made" for any US Manufacturers (you may need quickly research a brand if you are not sure since this will not always be specifically labeled)

Note: Keep in mind that titles have a maximum limit of 80 characters.

Additional Specifications & Special Condition

The Additional Specifications section should be used for any secondary labeling or additional measurements that do not fit in the other sections of the listing. There is no character limit here so any relevant information that is not already covered should be included (within reason - we don't want to overload the listing with unnecessary information, so ask your trainer if you are not sure whether or not to include something in this section).

The Special Condition section should be used for any special notes about the item's condition such as damage or modification. Try to be specific when describing the condition, and reference pictures that point out the damage / modification if applicable. For example, "This is missing two insert screws" or "One of the pockets is damaged - see picture #4 for details". General wear and tear does not need to be mentioned, but anything that will affect the tool's usage should be included here.

Once all information is entered, click here for the next steps.