Indexable drills use replaceable inserts which can be changed out when they get worn down, greatly extending the life and usability of the tool.

Indexable drills are sometimes easily mistaken for Indexable End Mills. Here are some things to look out for that can help differentiate the two:

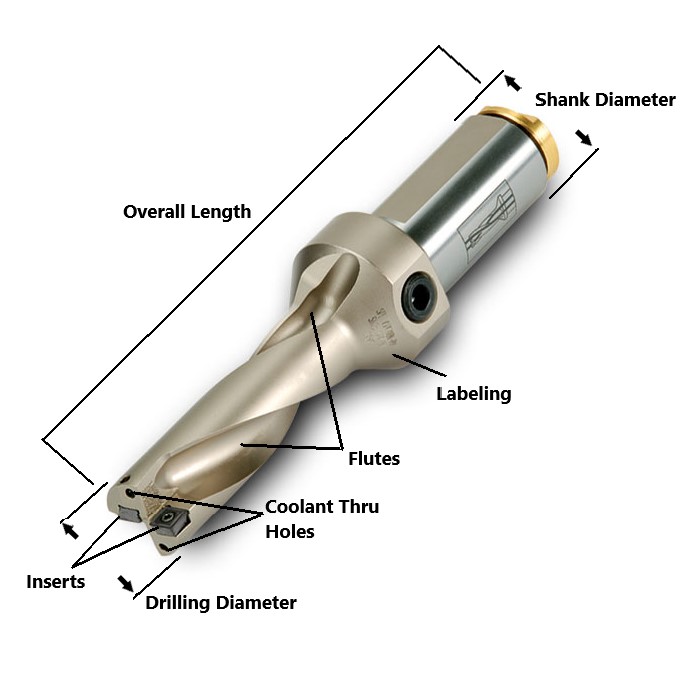

1. Flute Type - Indexable drills usually (but not always) have spiraled flutes, like the one shown in the diagram above. Indexable end mills, meanwhile, almost always have straight flutes.

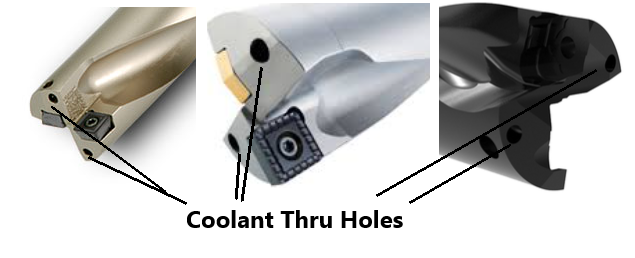

2. Coolant Thru Holes - A coolant-through drill will have coolant holes at the tip of the drill, while a coolant-through end mill will have coolant holes along the sides of the flutes.

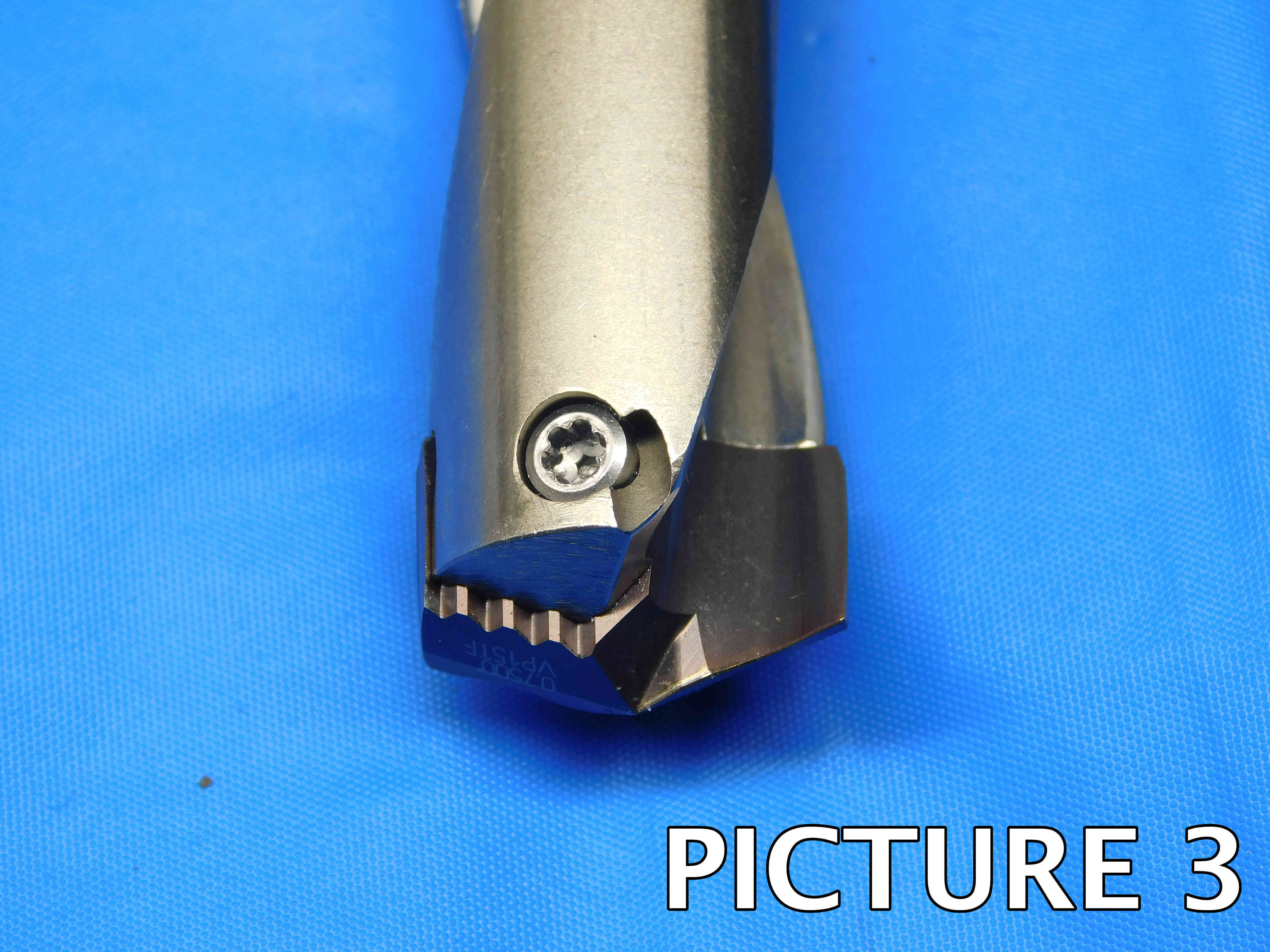

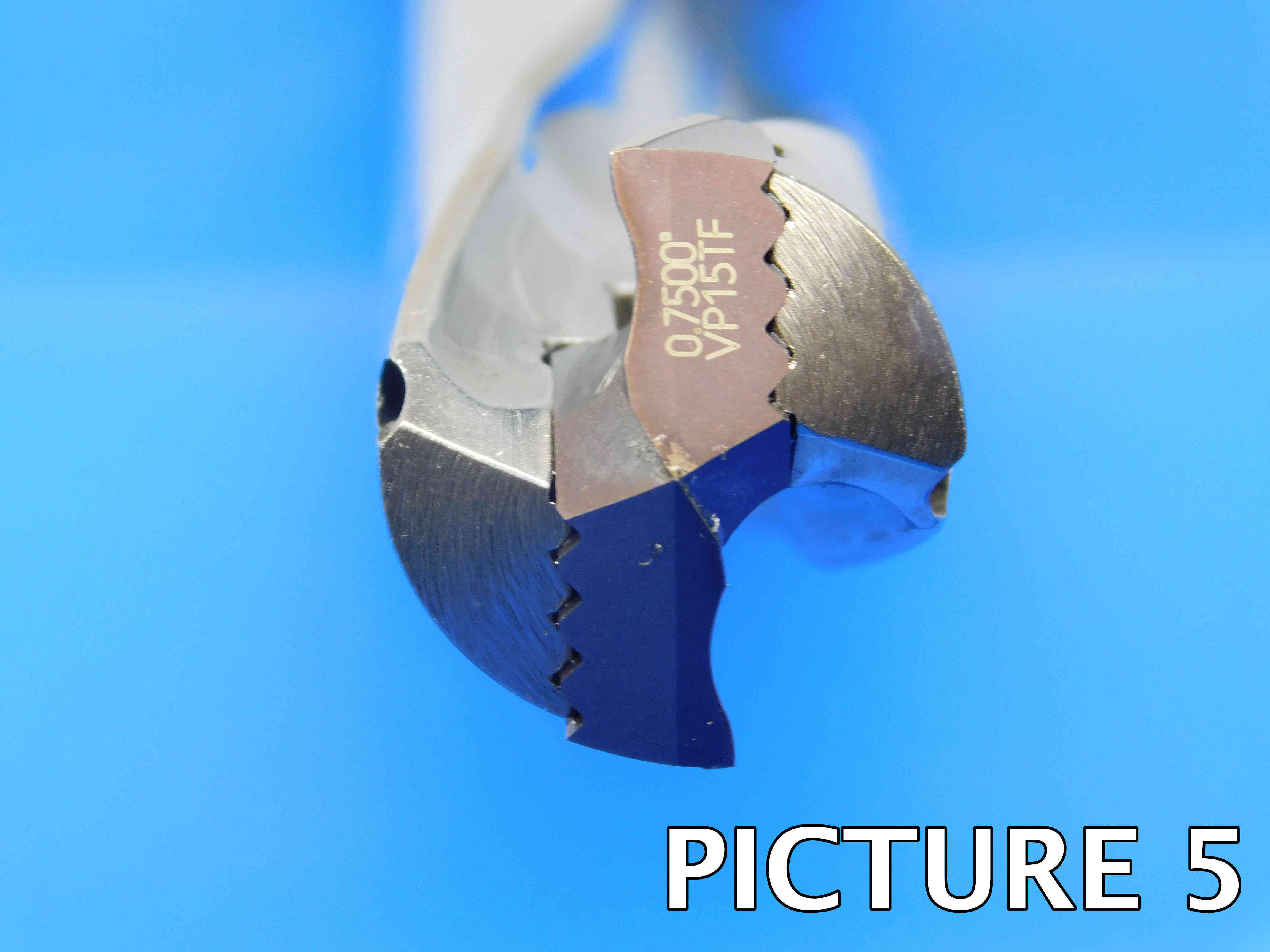

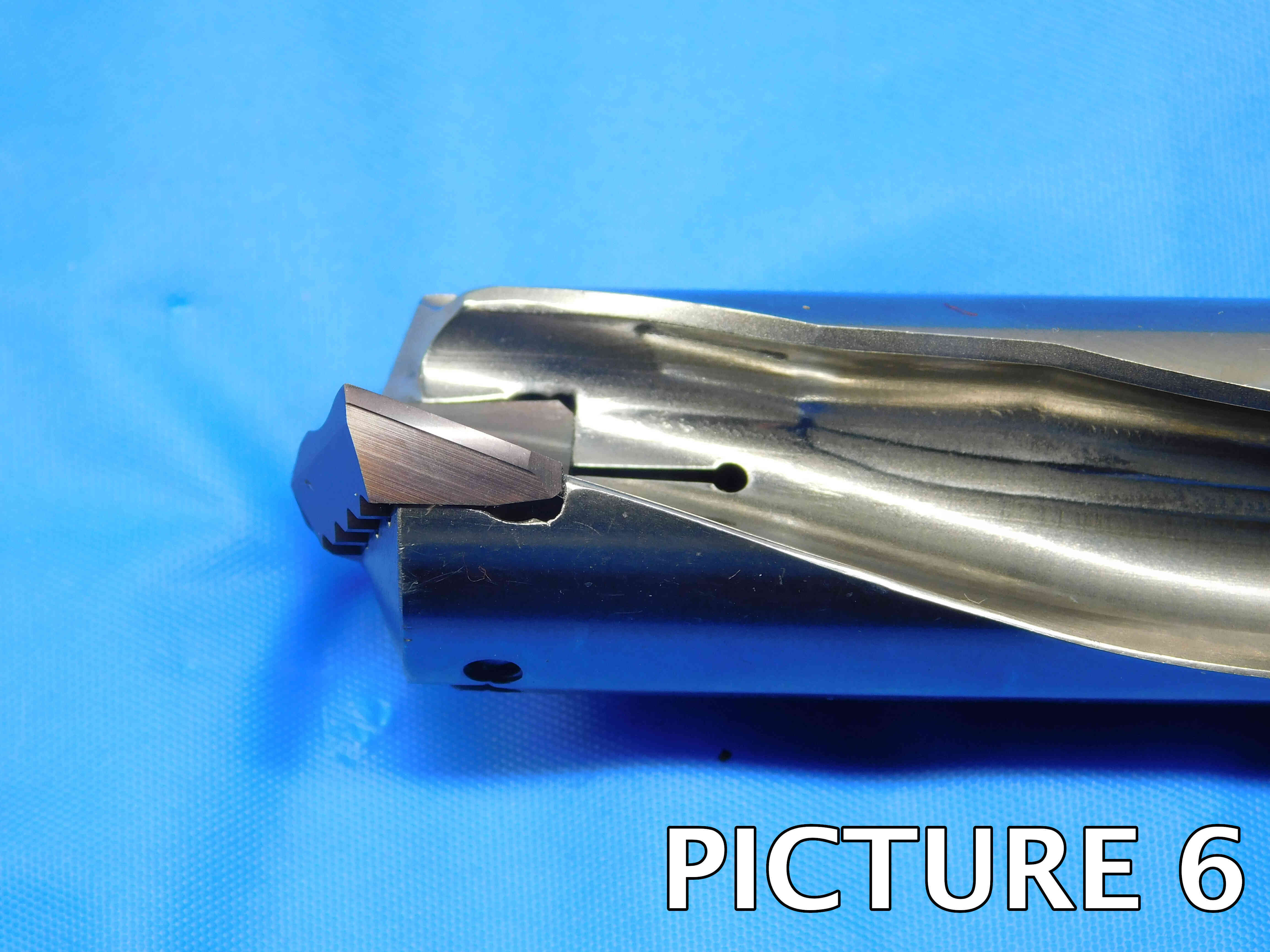

3. Insert Position - The inserts in an indexable drill are often spaced unevenly, with one on the outside edge (called the "peripheral insert") and one closer to the center (the "central insert"). This can be seen in the example drill pictured above. Additionally, the inserts frequently (but not always) are angled to create a pointed tip at the center. Indexable end mills, meanwhile, typically only cut along the edges of the flutes and not the center. Center-cutting indexable end mills do exist, however, but will typically have all of their inserts touching the outer edges of the flutes rather than the offset style used by many drills.

4. Number of Flutes - Indexable drills almost always have only two flutes, while indexable end mills often have three or more - so if an indexable tool has more than two flutes, it is likely an end mill and not a drill.

Use WD-40 and a Scotch-Brite pad to remove any rust or residue from the drill, especially in and around the insert pockets. Be careful not to damage any labeling while cleaning. Wipe down with a dry rag before taking pictures to remove any excess moisture.

Click here for info on how to upload pictures

1st Picture: A three-quarters (or "3D") shot of the drill, with the working end facing the camera. Make sure that at least one of the inserts (or insert pockets) is fully visible in this picture. If there is any packaging or other included items, they should be in this picture as well.

2nd Picture: A side view of the drill, with a tape measure at the bottom of the frame to provide size reference. Like the first picture, make sure that one of the insert pockets is fully visible. If there is labeling on the drill, it should be visible if possible and readable (i.e., right-side up). Any packaging should be included in this picture as well.

Note: If you have packaging with labeling on it, make sure that it actually matches the drill - and if it does not, black out the package labeling with a marker. It is not uncommon for used tooling to end up in non-original packaging, and we do not want to cause any confusion by having incorrect brands or part numbers showing in the pictures.

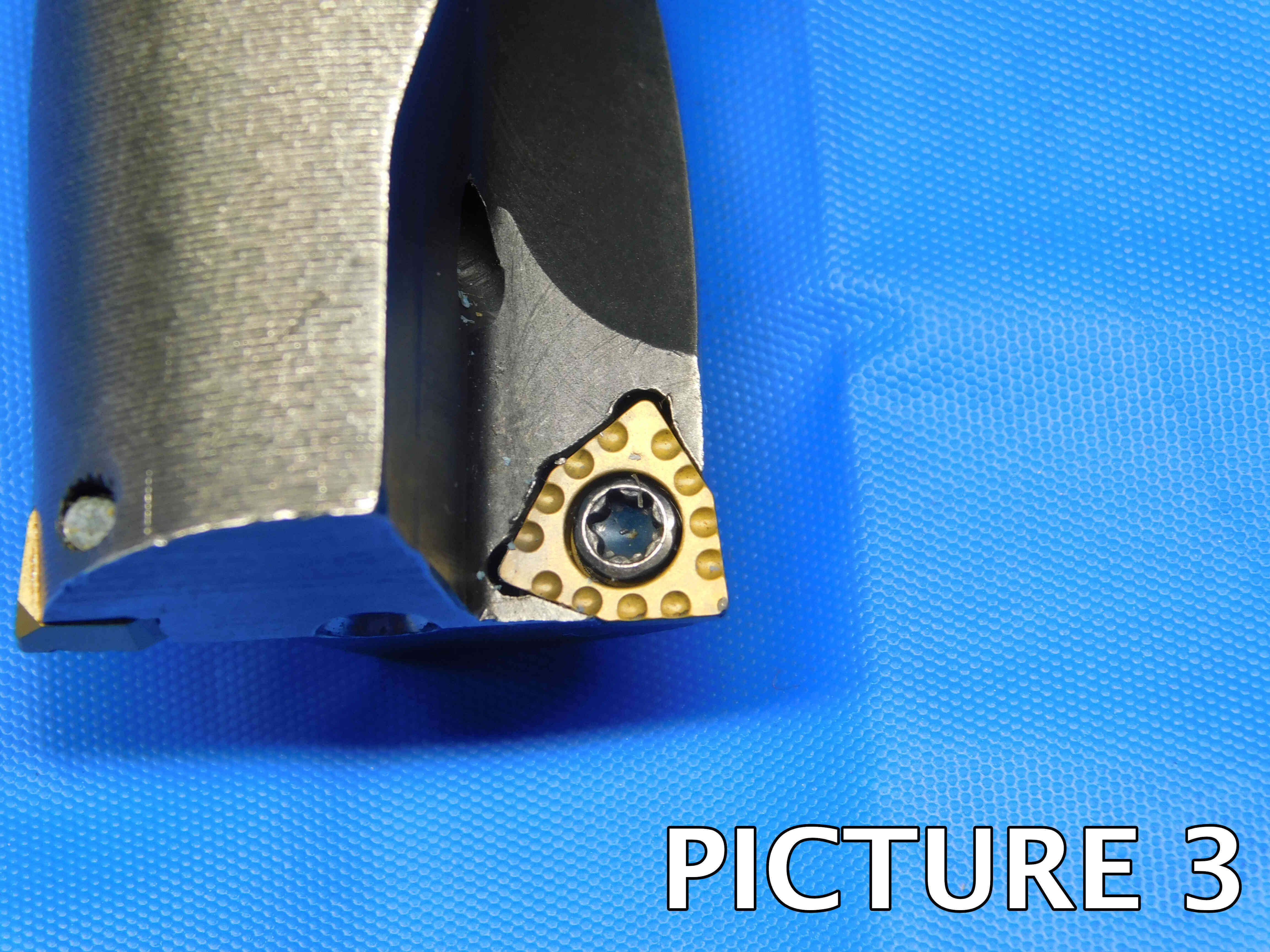

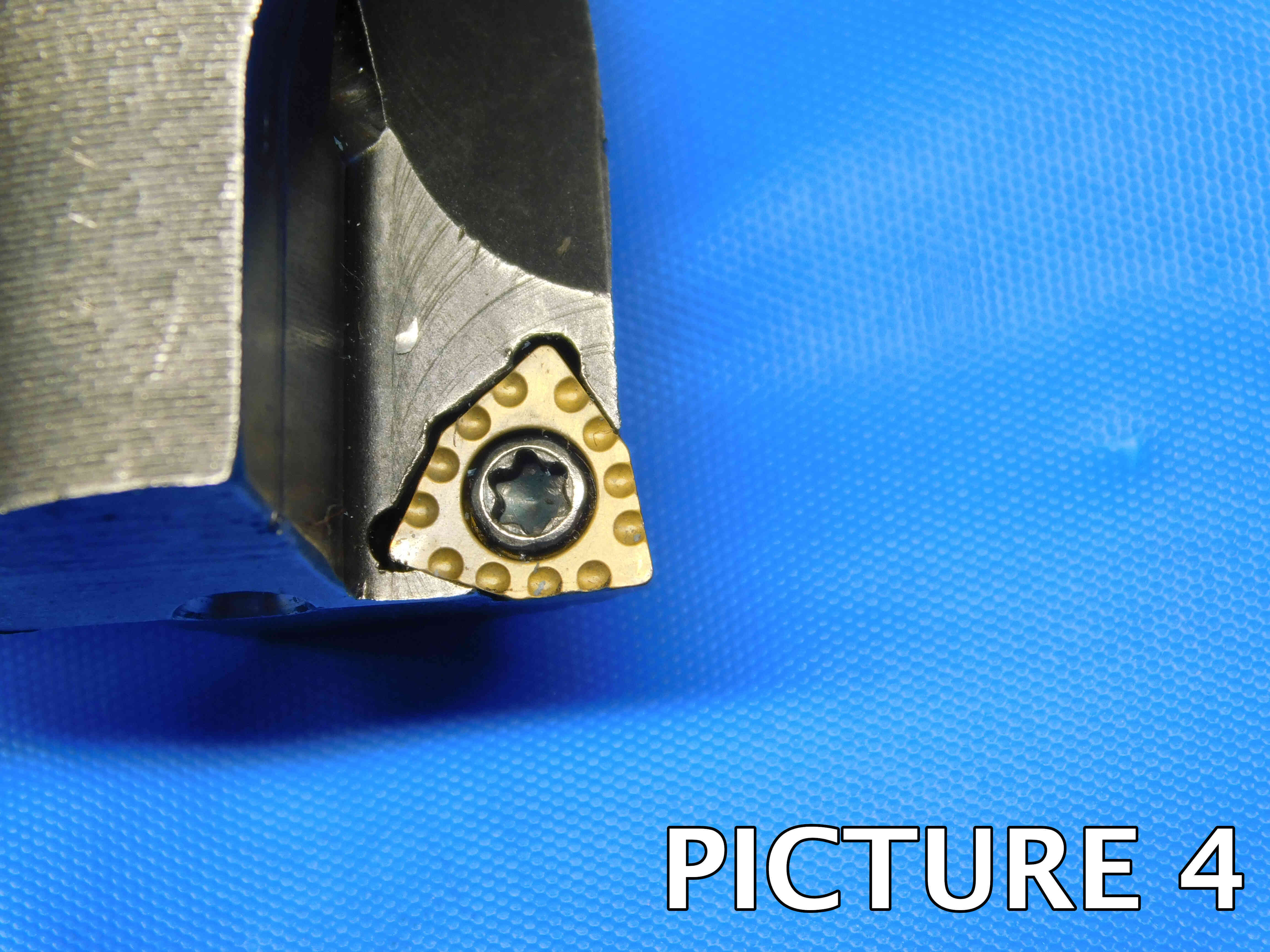

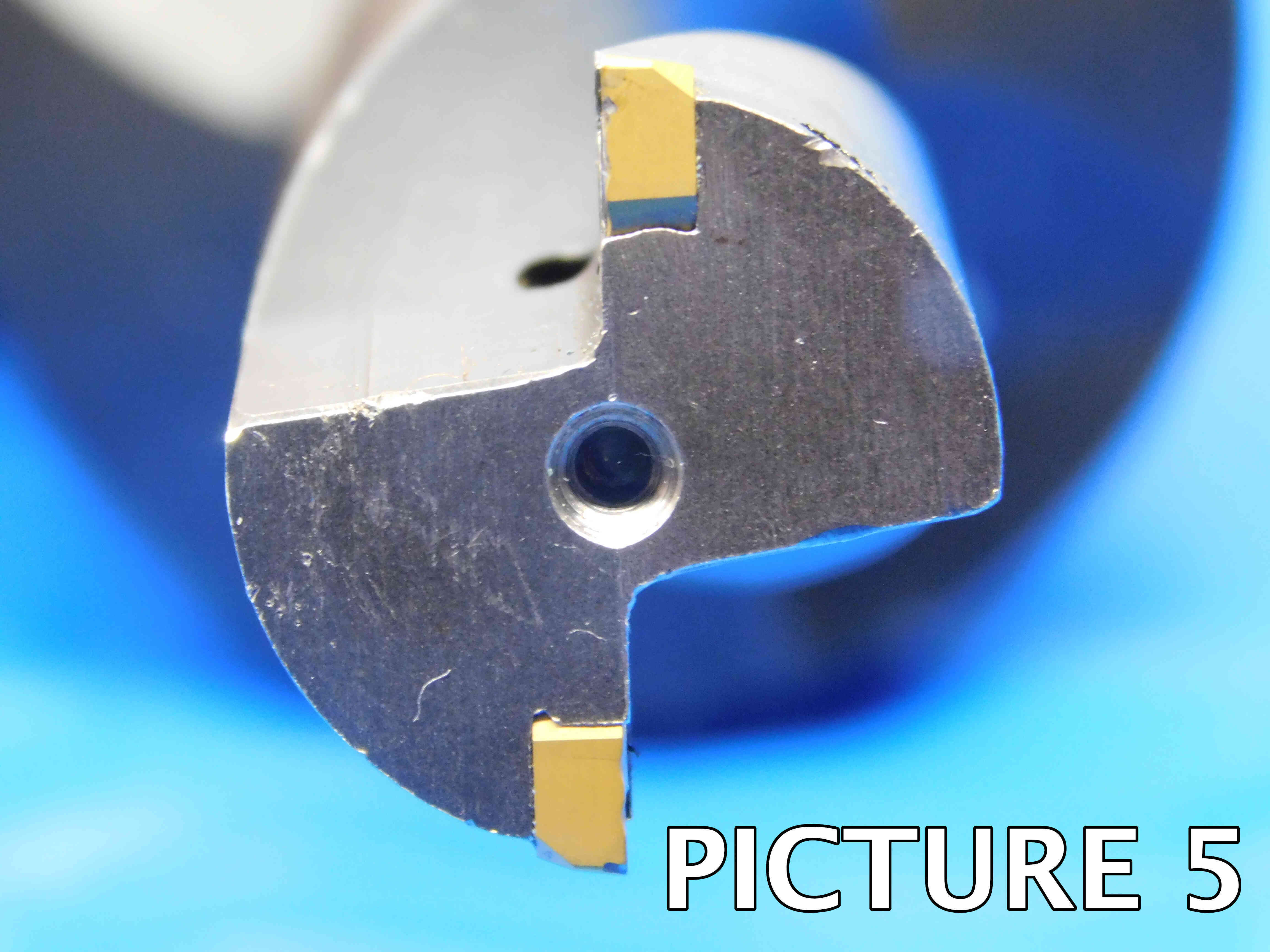

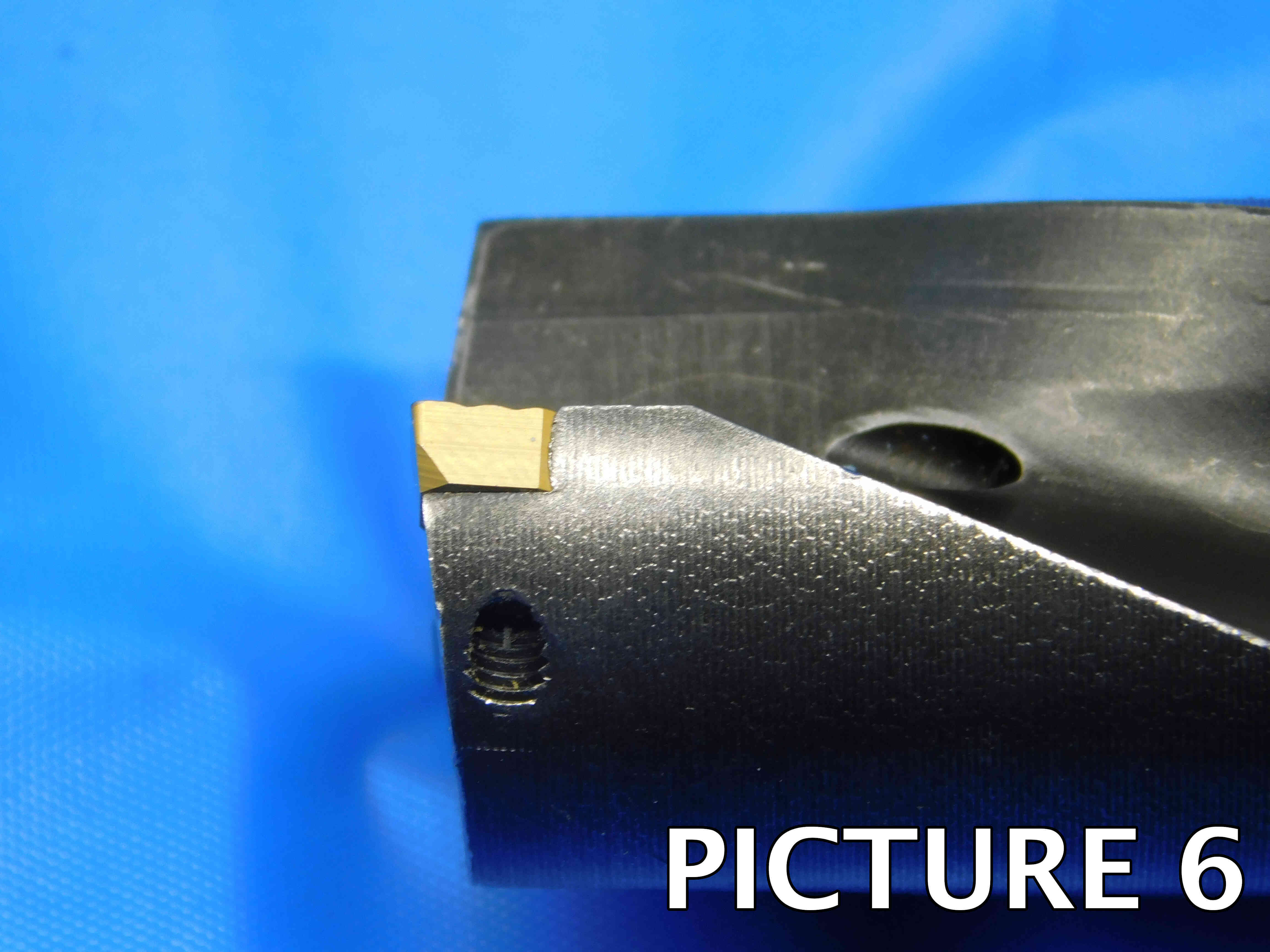

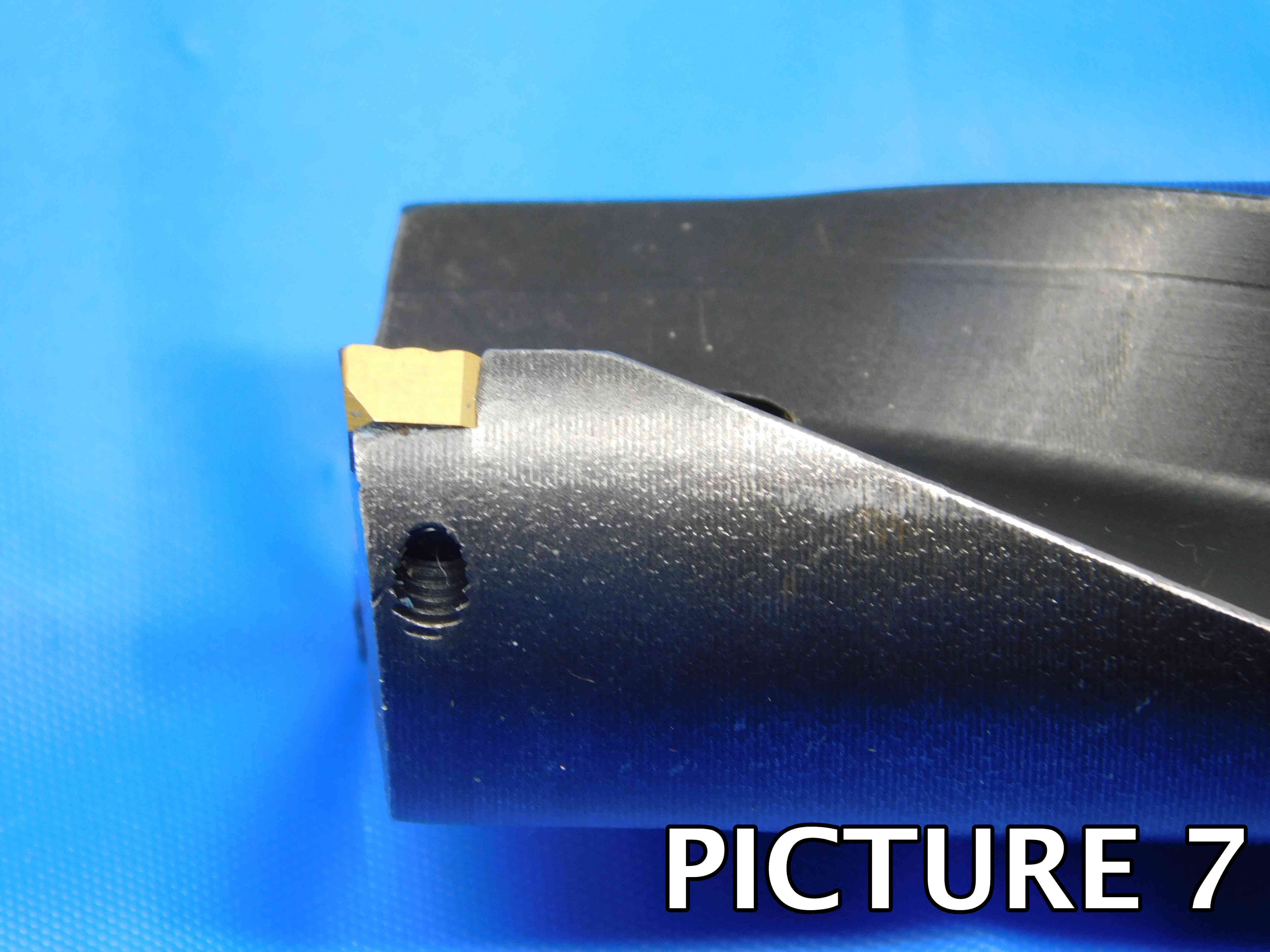

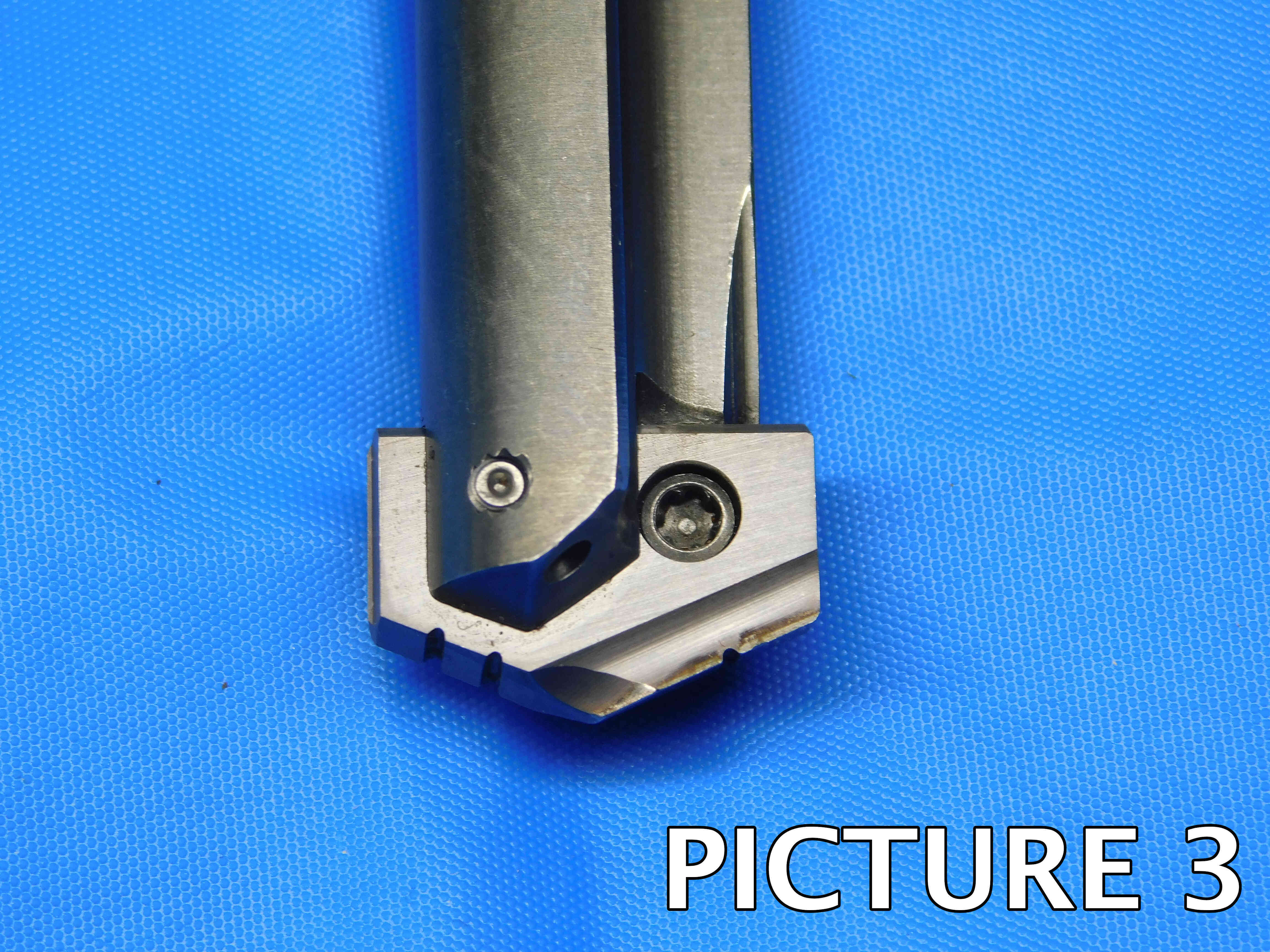

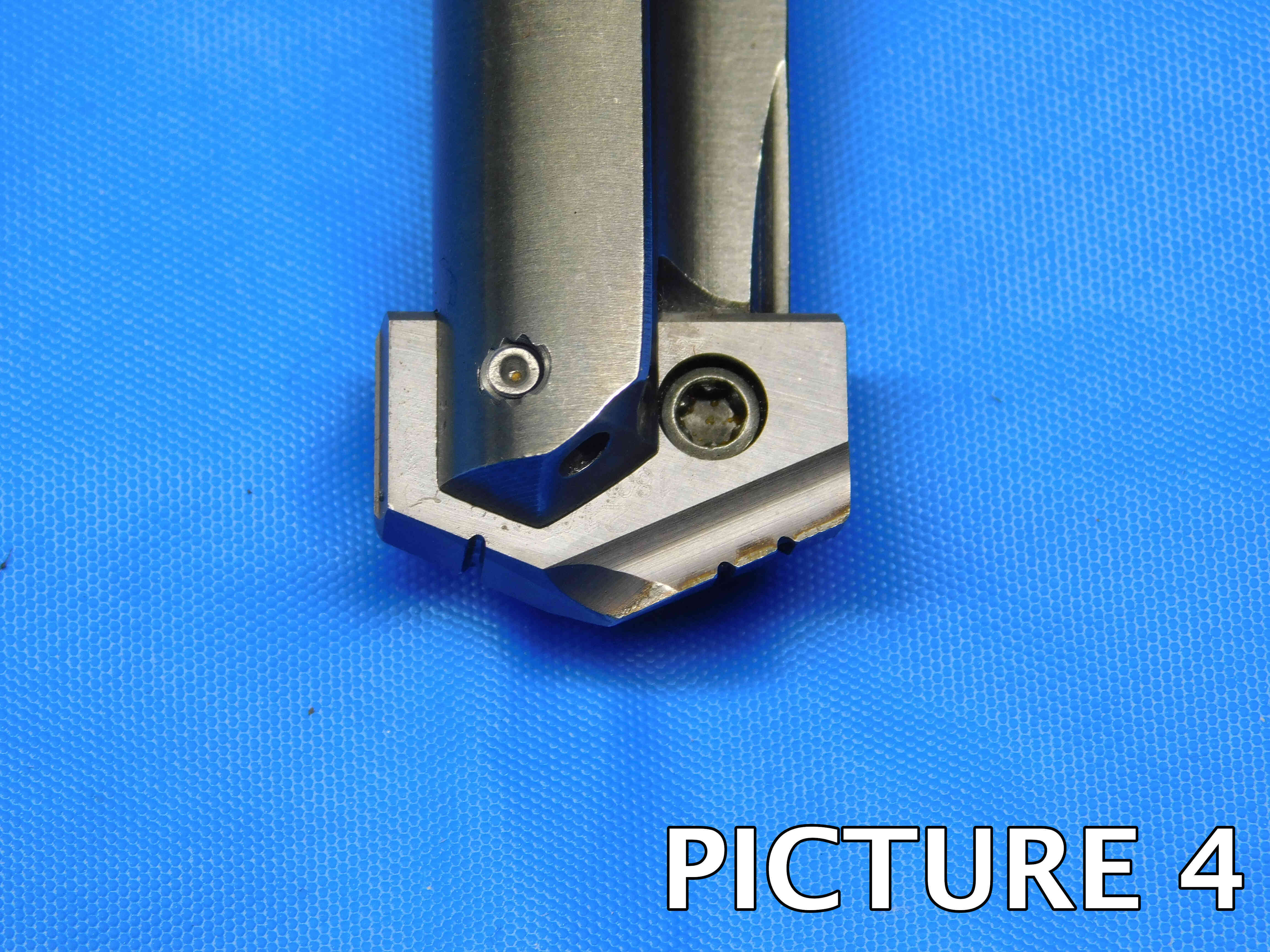

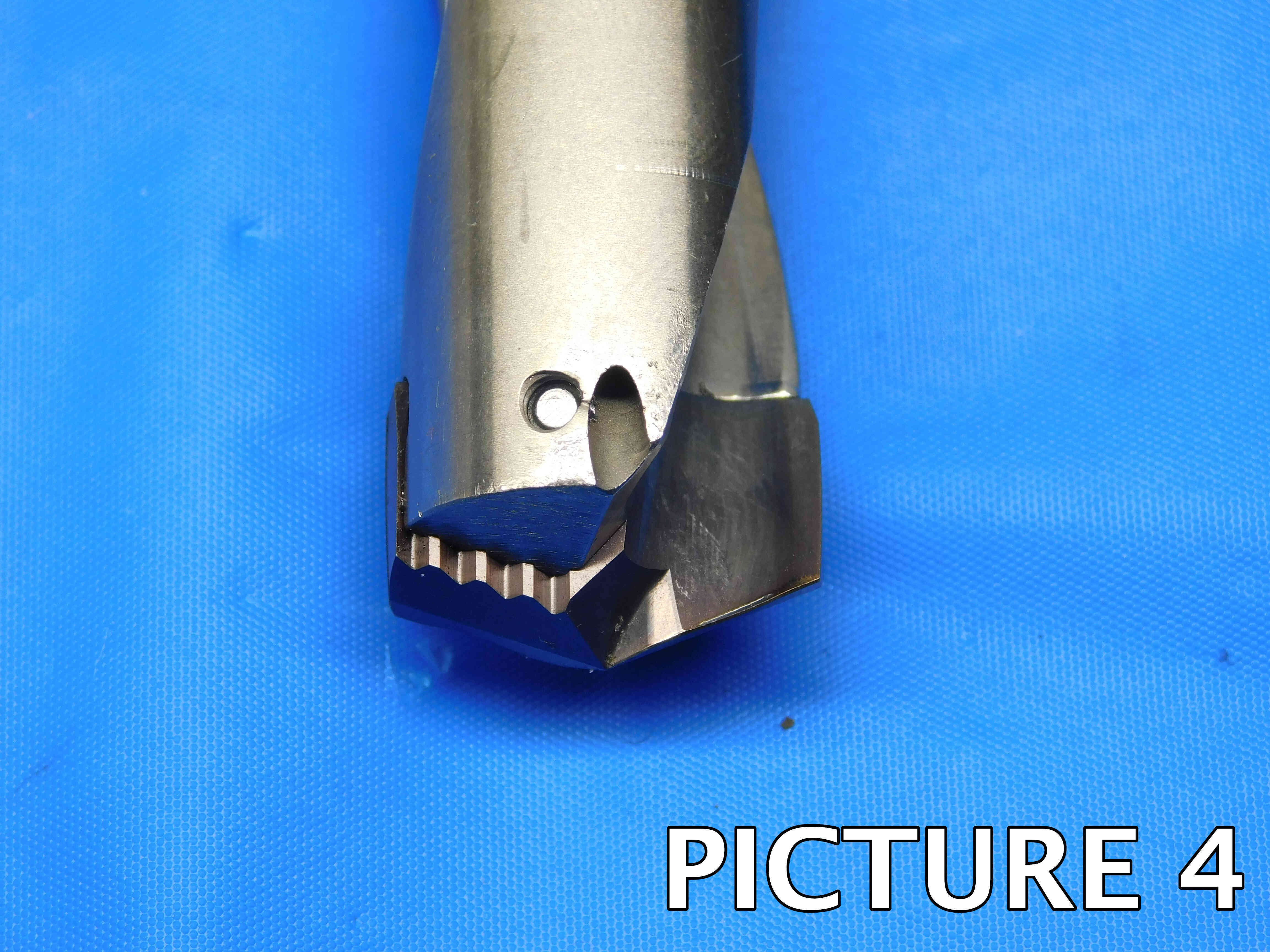

3rd through 7th Pictures: Five (or more) pictures of the insert pocket(s), taken at specific angles:

- A top-down view of each pocket* (2 pictures)

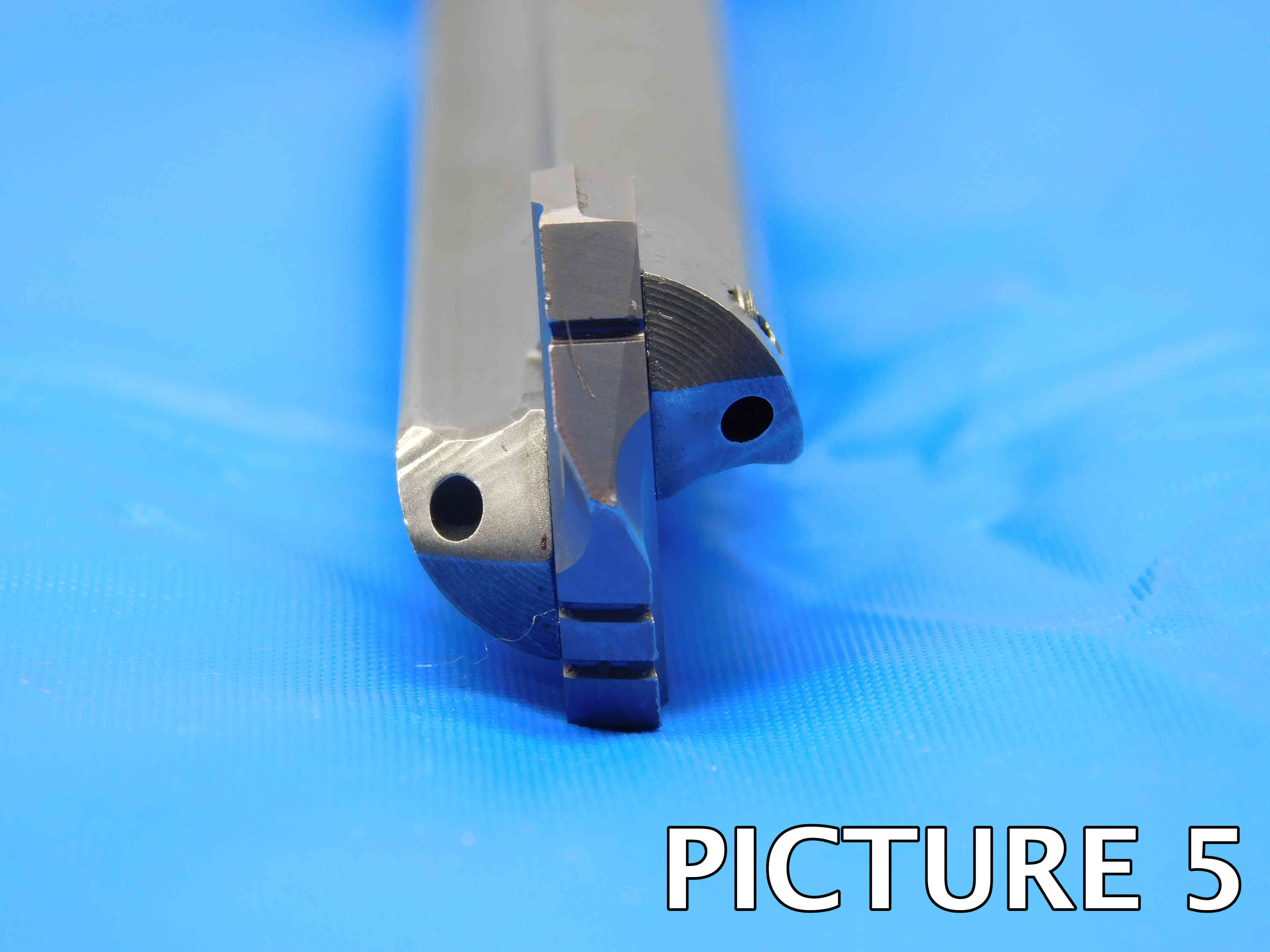

- A head-on picture, turned 90 degrees so the bottom of each pocket is visible (one or two pictures - will depend on size of drill / if both pockets can be shown clearly in one picture)

- A side view of each pocket* (2 pictures)

*For spade drills / other drills with only one insert: Take pictures of both sides of the pocket as shown in examples below

All five pictures must be present on all used indexable drills and must match the examples shown below! The insert pocket is the most important part of the tool and the condition must be 100% clear in the pictures! ***If an indexable drill is NEW, you may take just the top-down picture of one pocket and skip the other four, as there will be no wear / damage that needs to be shown***

8th Picture: A close-up shot of the labeling. Depending on the size of the drill and the location of the labeling, this may require more than one picture, such as in the first example below. If there is no labeling, or if it is too faded too show up in a picture, skip this picture.

Additional Pictures: Any damage or modifications, especially to the insert pockets or shank, must be clearly pictured. Use a pen to point to the damaged / modified areas. Refer to the second set of pictures below for an example. If any of the insert pockets are missing their screws, it MUST be pictured as well as mentioned in the "Special Condition" section. If there are any flat sections on the shank (whether manufactured or modified) which are not clearly visible in the previous pictures, they should be shown in an additional picture as well. If you think you may need additional pictures for any other reason, check with your trainer to see if they are necessary.

Please refer to the examples below:

If there is no brand labeled, click the "Unlabeled" button to the right of this cell. Make sure this cell is not left blank, or the listing will not upload properly. Note: Items are often labeled with the country of origin (USA, China, Japan, Poland, etc). This should NOT be entered as the brand, and furthermore should not be included in the listing at all EXCEPT for USA which can be used as a filler.

Indexable drills may be designed to be coolant thru / fed in order to protect the tool & workpiece from overheating. This can be identified by unthreaded holes at the tip of the drill that will connect to a central hole at the side or end of the shank where the coolant enters. Threaded holes that are used by the insert screws ARE NOT coolant thru holes.

***Be sure to also read the following section about Exchangeable Tip Drills, which are often confused for Spade Drills.***

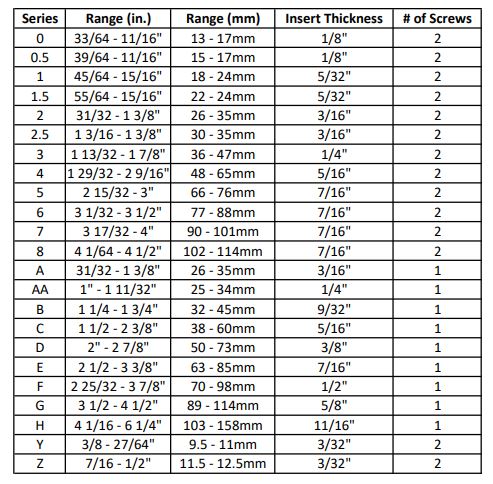

While most indexable drills have only a single, set drilling diameter, spade drills are able to cover a range of different sizes. These drills hold a single insert which is typically rectangular or pentagon-shaped and can be freely replaced with differently sized inserts within the same insert series.

The insert series used by a spade drill is very important to include in the listing whenever possible. This information will sometimes be labeled, or you may be able to find it by searching the part number online and finding a product page from the manufacturer or a reputable distributor. The easiest way to determine the insert series of a spade drill is by measuring the width of the insert or insert seat, noting the number of screws used to hold the insert in place. This will correlate to the insert series as described in the chart below:

Please note that, while these are some of the most commonly used spade drill inserts, this list is not all-inclusive, and some specific manufacturers may use their own proprietary insert sizing. If you are listing a spade drill that does not seem to fit into the chart above, and you are not able to determine anything about the inserts from the drill's labeling, be sure to at least include the insert's thickness and screw hole size(s) in the "Additional Specifications" box.

One of the most common brands for spade drills is Allied Machine & Engineering Corp. (AMEC). AMEC spade drills (and inserts) use a standardized labeling scheme which is described in the link below, which may be useful for identifying spade drills with worn / illegible labeling:

https://www.samtectools.com/pdf/drilling/amec-T-A-&-Gen-2-T-A-Drills.pdf

Another type of indexable drill which is often confused for spade drills (exchangeable tip drills are NOT spade drills!), these drills use replaceable drill tips which are typically held in place by a central locking pin rather than screws (some do have set screws as well, but they will be located further down the body than on a spade drill). Like spade drills, they can cover a range of cutting diameters, however the range will generally be much smaller than a spade drill (often only 1-2mm).

If a replaceable tip drill is currently holding an insert, you will be able to differentiate it from a spade drill by the fact that the sides of the insert will be rounded and will line up very closely with the diameter of the drill body itself, versus a spade drill insert which will have flat sides that often extend out beyond the drill body.

If a replaceable tip drill is not currently holding an insert, you will be able to differentiate it from a spade drill by the fact that there are no screw holes for holding an insert that run horizontally through the drill body, but instead there will be a hole in the center of the working end for the insert's locking pin (the locking pin can be seen in the images above).

The cutting diameter will often be indicated by labeling, or may be found on a manufacturer's product page by searching the part number online. If the cutting diameter cannot be determined from the labeling, it can also be measured with calipers:

-On an indexable drill where both inserts are at the edges of the flutes, you can simply measure the distance from the outside edge of one insert across to the outside edge of the opposite insert.

-For indexable drills with offset inserts (where one is at the edge of the flute and the other is towards the center of the drill), the cutting diameter is more difficult to measure accurately. Measuring from the outer insert across to the edge of the opposite flute will get you close to the cutting diameter, but this measurement will be slightly smaller than the true drill size due to the small amount of extra length added by the peripheral insert when it travels to the opposite side (usually this is a distance of about 1/16"). In most cases this measurement should be close enough to a common fractional size that you will be able to determine the drilling diameter, but if you are not sure, contact your trainer for a second opinion.

-For spade drills, list the full insert series range if that information is available. If you are not sure of the insert series / range for a spade drill, list the cutting diameter of the insert it currently holds - or, if it does not currently hold an insert, this can be left blank, but this is a last resort only if there is no other information for us to go off of.

Note: When entering a whole-number inch size, always include the " sign. The " sign should not be included for any size including a fraction or decimal. So, for example: If an drill's cutting diameter is exactly one inch, it should be entered as 1" and not just 1. If the cutting diameter is one and a half inches, it should be entered as 1 1/2 or 1.5 and not 1 1/2" or 1.5".

Metric size measurements should be entered with a lowercase "mm" (ex.: 16mm, 40mm).

The overall length is very simple; measure the distance between the farthest two points on the tool. This can be done with handheld calipers or even a tape measure as this does not need to be as precise as other measurements.

The shank diameter can be measured with calipers and is often a common size, however this is a precise measurement and should not be rounded if it is more than .005" off from a common size. You may also encounter indexable drills with special modular connections such as CAPTO or ABS which are designed to fit into specific machines or tool holders. For more information on these connection types, please refer to the Modular Connection Types page.

The vast majority of indexable drills have two flutes, although you may occasionally find one with more than two, or even just a single flute. Note that the number of flutes is not necessarily equal to the number of inserts held, as most spade drills and exchangeable tips drills have two flutes but only one single insert. Similarly, you may encounter indexable drills that hold more than one insert per flute (though these are also uncommon).

The type of inserts held by an indexable drill will sometimes be directly labeled on the drill itself, often notated by the letters "INS" or even a picture of an insert, or you might be able to find this information from a manufacturer's website or catalog using the drill's part number. Some types of inserts can also be identified based on certain aspects such as shape and dimensions - for more information, refer to the Identifying Inserts page.

For spade drills, list the insert series here (including the word "series" - e.g., "SERIES A", "SERIES 3").

If you are not able to find any insert information for an indexable drill, this section can be left blank.

Labeling is often located on the shank and may include a variety of information including part number, type of inserts held, drilling diameter, and even part numbers for insert screws or screwdrivers. Information that is already covered by the previous sections (cutting diameter, inserts held, etc.) does not need to be included again here. If there is a large amount of additional labeling, enter just the main part number in this section and put the rest in "Additional Specifications."

The "Filler" section is used to add other relevant information to the title which is not covered by the other sections. Fillers can be a good way to increase a listing's visibility - we always want to include as much information as possible that we think a customer might be searching for in order to make sure that our listing is coming up in their search results.

There is not necessarily one right answer when it comes to fillers, and often it will be up to you to decide what should and should not be added as filler. Indexable Drills generally do not require much filler, but some possible fillers include:

-Secondary labeling or branding / product names

-"USA" or "USA Made" for any US Manufacturers (you may need quickly research a brand if you are not sure since this will not always be specifically labeled)

Note: Keep in mind that titles have a maximum limit of 80 characters.

Additional Specifications & Special Condition

The Additional Specifications section should be used for any secondary labeling or additional measurements that do not fit in the other sections of the listing. There is no character limit here so any relevant information that is not already covered should be included (within reason - we don't want to overload the listing with unnecessary information, so ask your trainer if you are not sure whether or not to include something in this section).

The Special Condition section should be used for any special notes about the item's condition such as damage or modification. Try to be specific when describing the condition, and reference pictures that point out the damage / modification if applicable. For example, "There is some damage around one of the insert pockets - see picture #5 for details." General wear and tear does not need to be mentioned, but anything that will affect the tool's usage should be included here.

Once all information is entered, click here for the next steps.