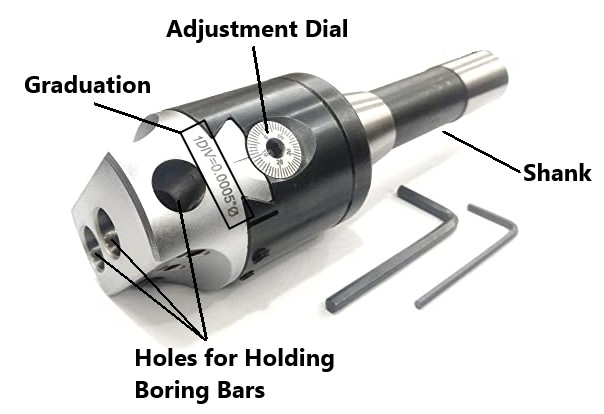

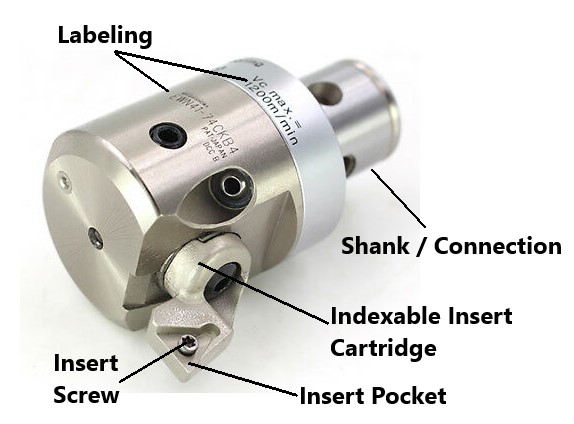

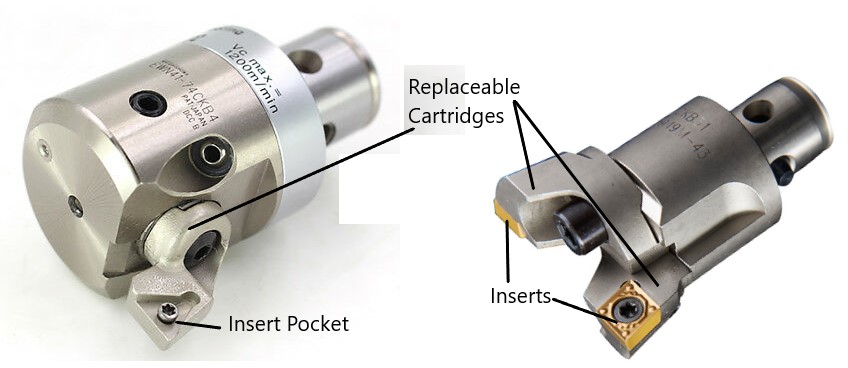

Boring heads are adjustable lathe attachments used to enlarge an existing hole. Some boring heads are designed to hold a boring bar using set screws (such as the one pictured above on the left), while others use indexable cartridges to hold inserts directly (such as the one pictured above on the right).

Boring heads come in many different styles and appearances, and not all of the categories described below will necessarily apply to all boring heads. Use your best judgement when listing boring heads to determine which information is relevant, and as always contact your trainer if you have any questions.

Use WD-40 and a Scotch-Brite pad to remove any rust or residue from the boring head, being careful not to damage or remove any labeling. Wipe down with a dry rag prior to taking pictures to remove any finger prints or excess residue.

Click here for info on how to upload pictures

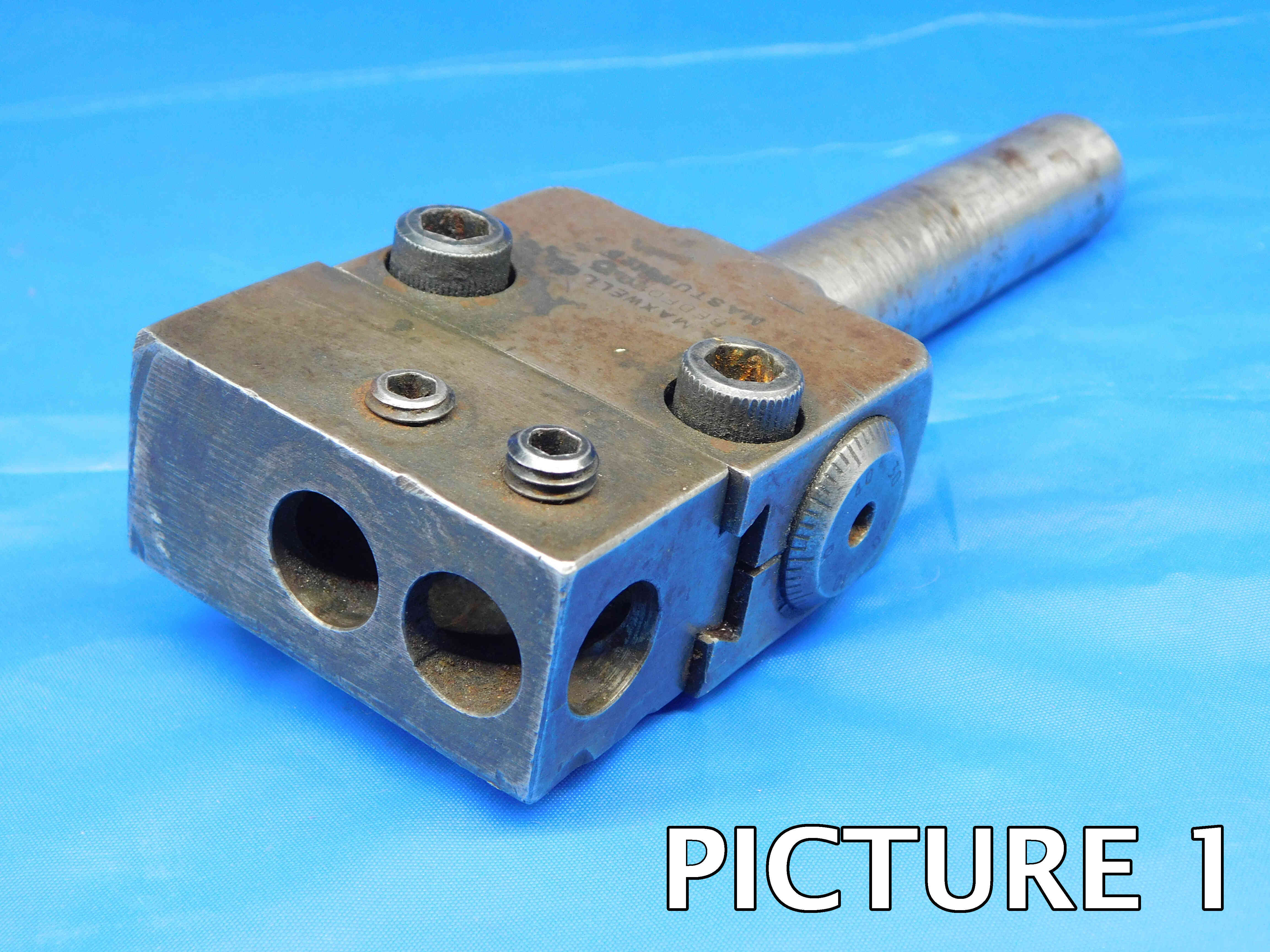

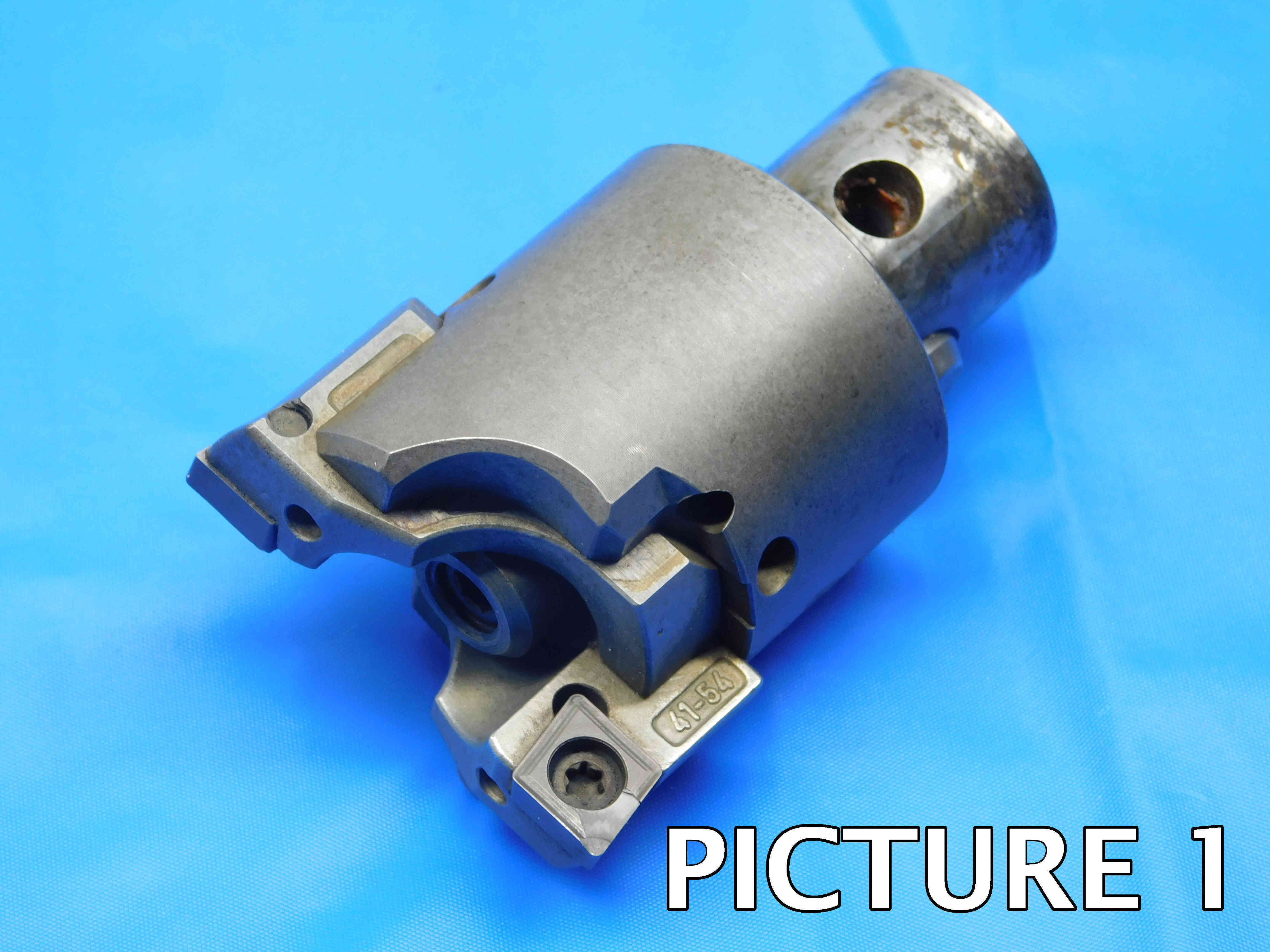

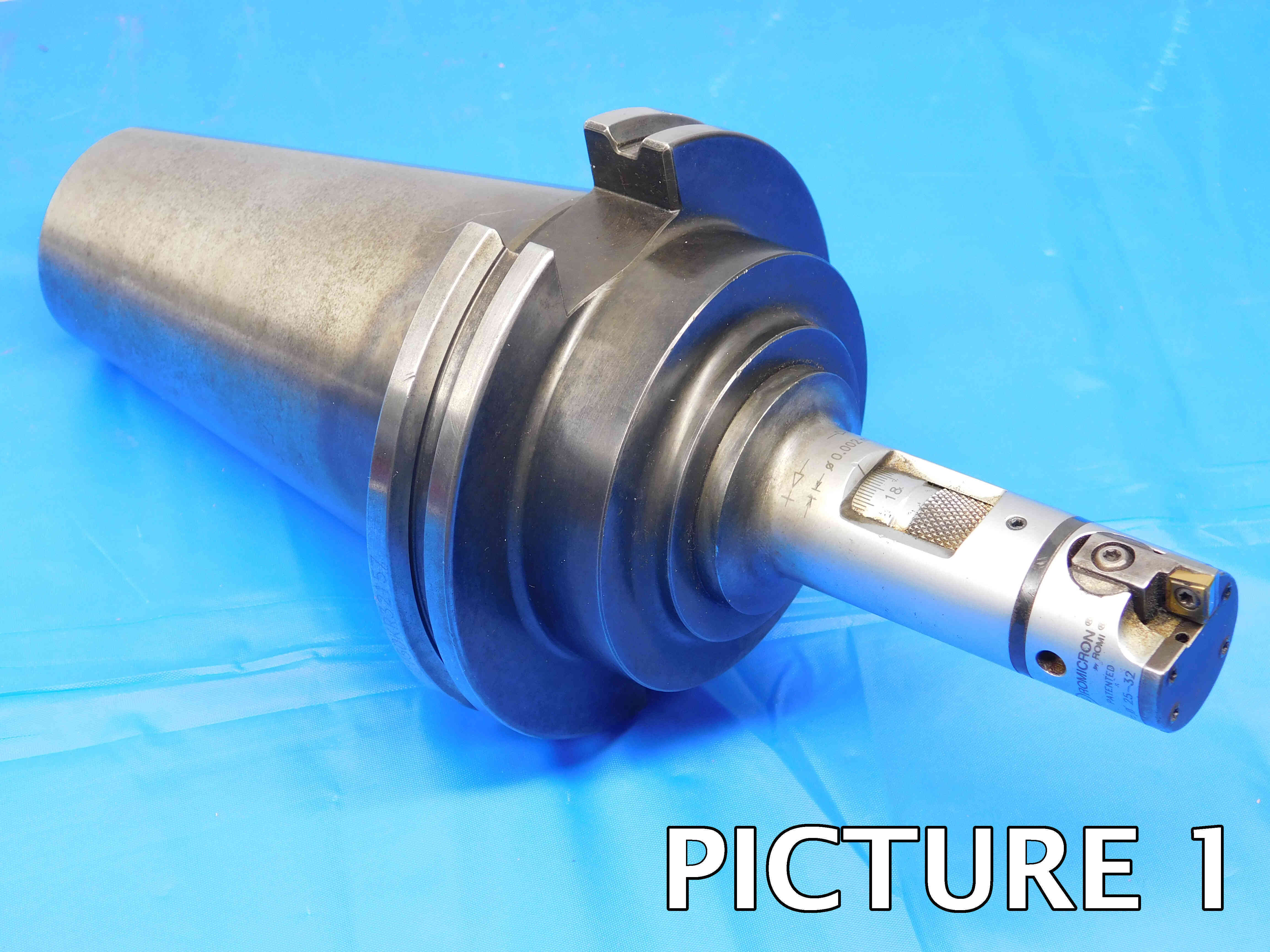

1st Picture: A three-quarters (or "3D") shot of the boring head, with the working end facing the camera. If the boring head is indexable, make sure that at least one of the inserts (or insert pockets) is fully visible in this picture. If there is any packaging or other included items, they should be in this picture as well.

2nd Picture: A side view of the boring head, with a tape measure at the bottom of the frame to provide size reference. Like the first picture, make sure that one of the insert pockets is fully visible (if applicable). If there is labeling on the boring head, it should be visible if possible and readable (i.e., right-side up). Any packaging should be included in this picture as well.

Note: If you have packaging with labeling on it, make sure that it actually matches the boring head - and if it does not, black out the package labeling with a marker. It is not uncommon for used tooling to end up in non-original packaging, and we do not want to cause any confusion by having incorrect brands or part numbers showing in the pictures.

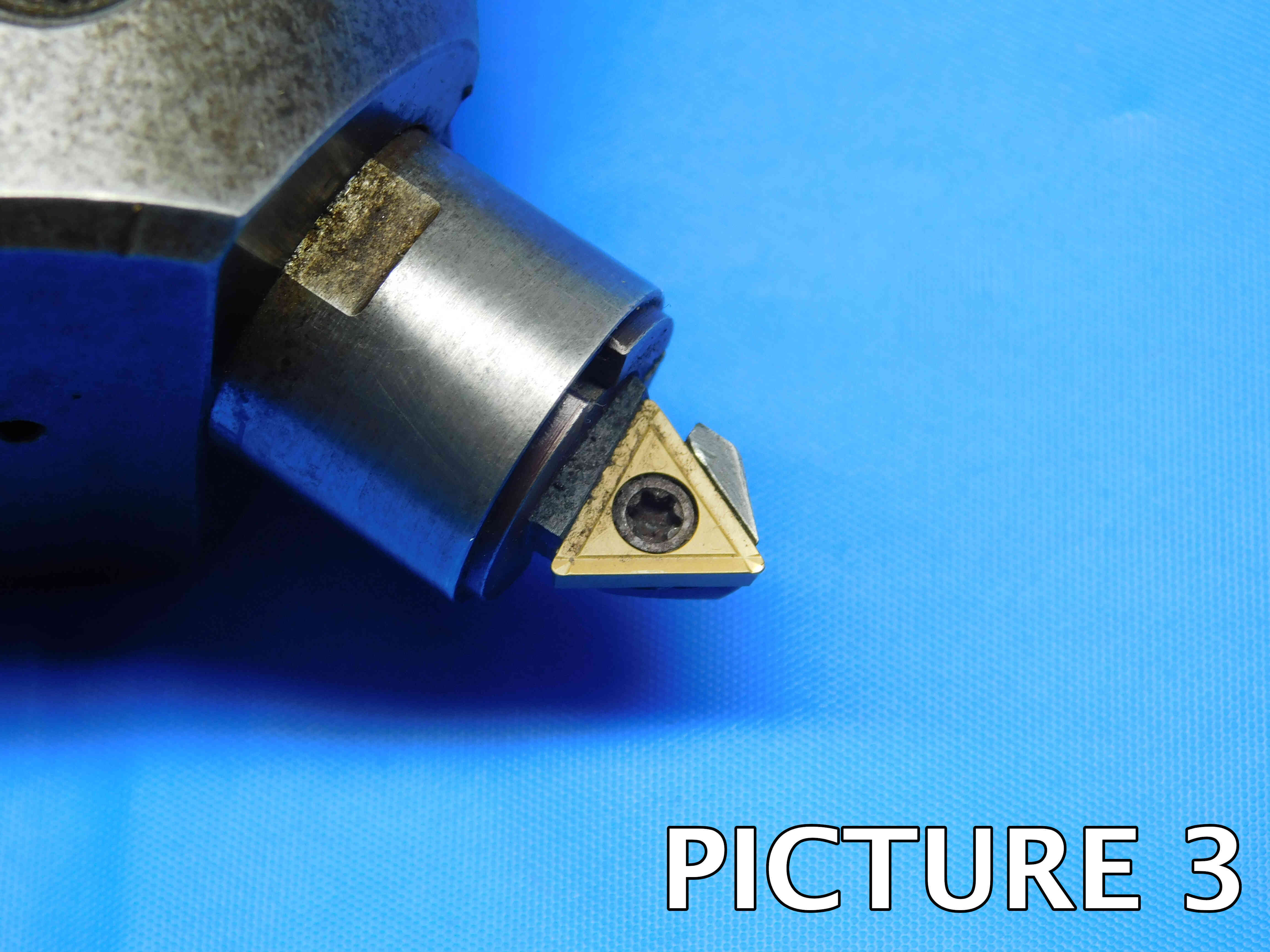

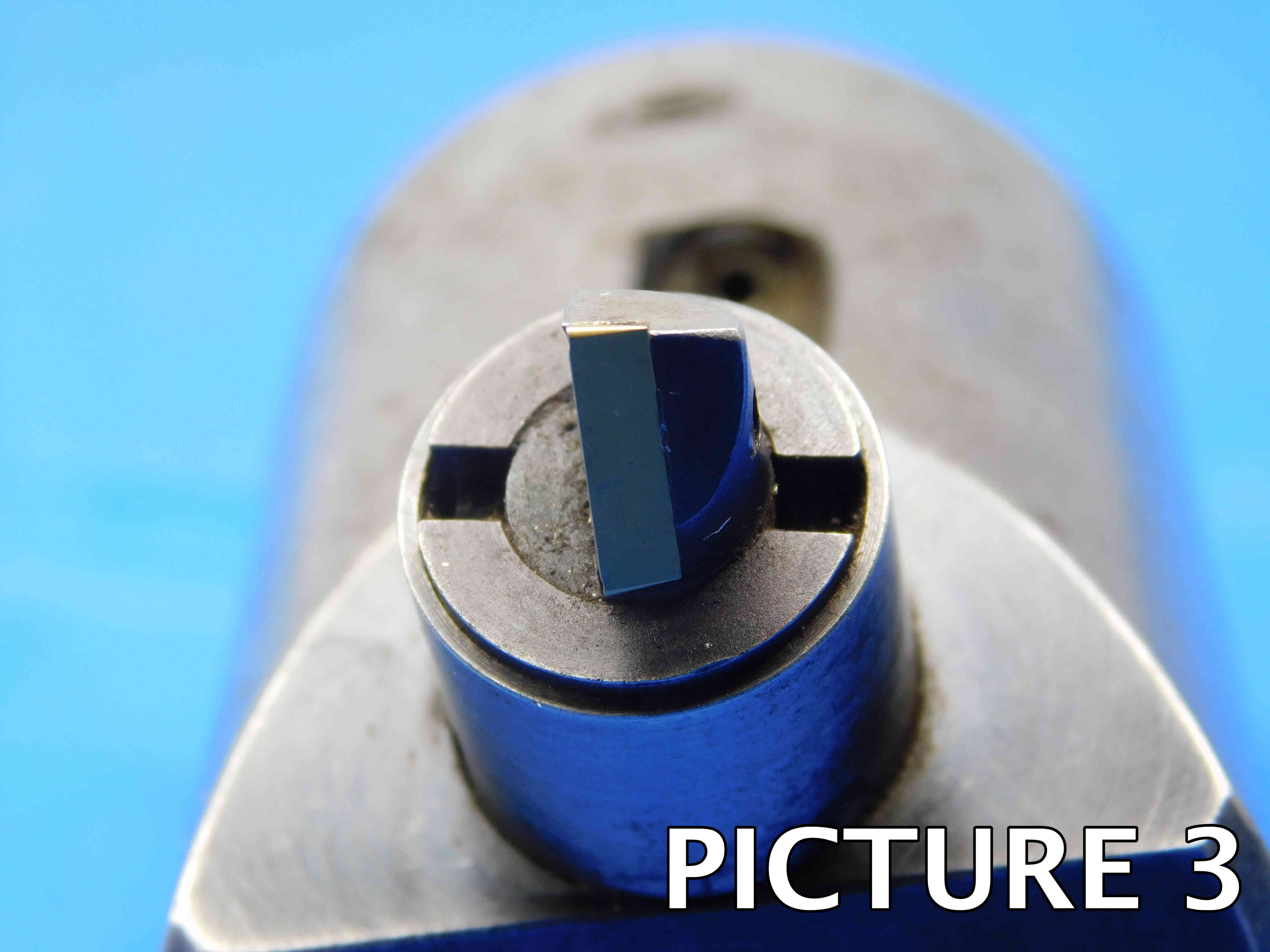

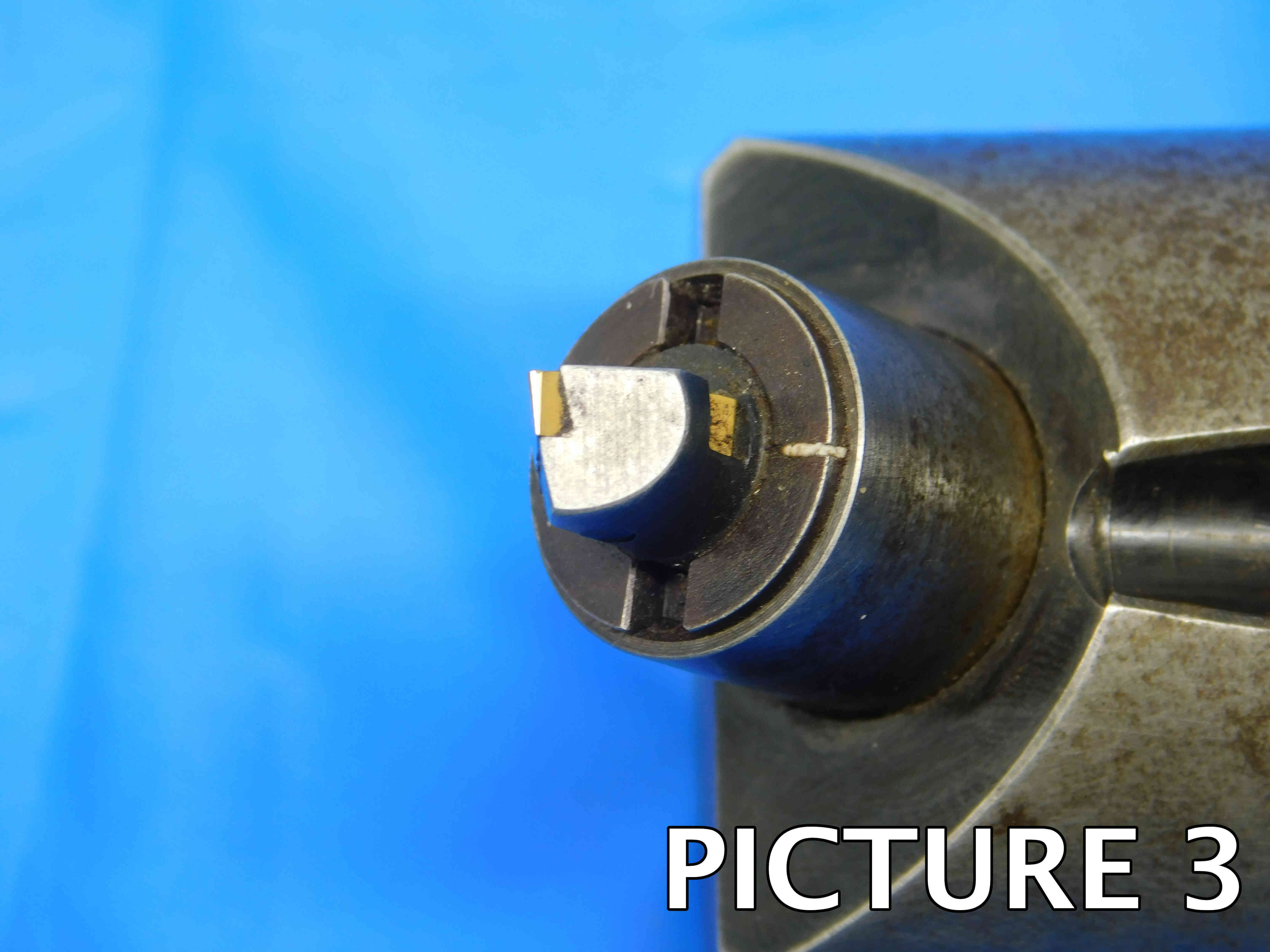

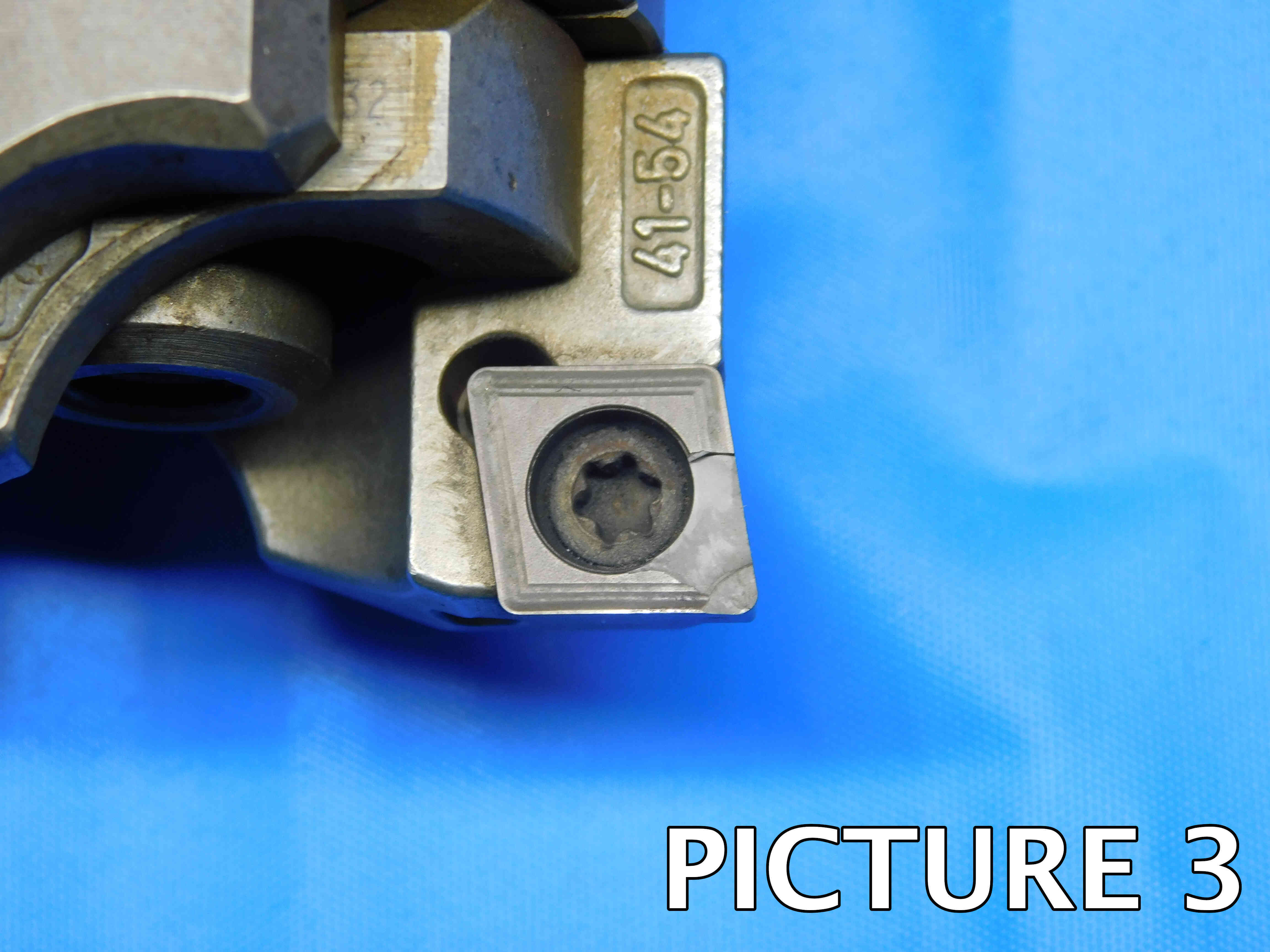

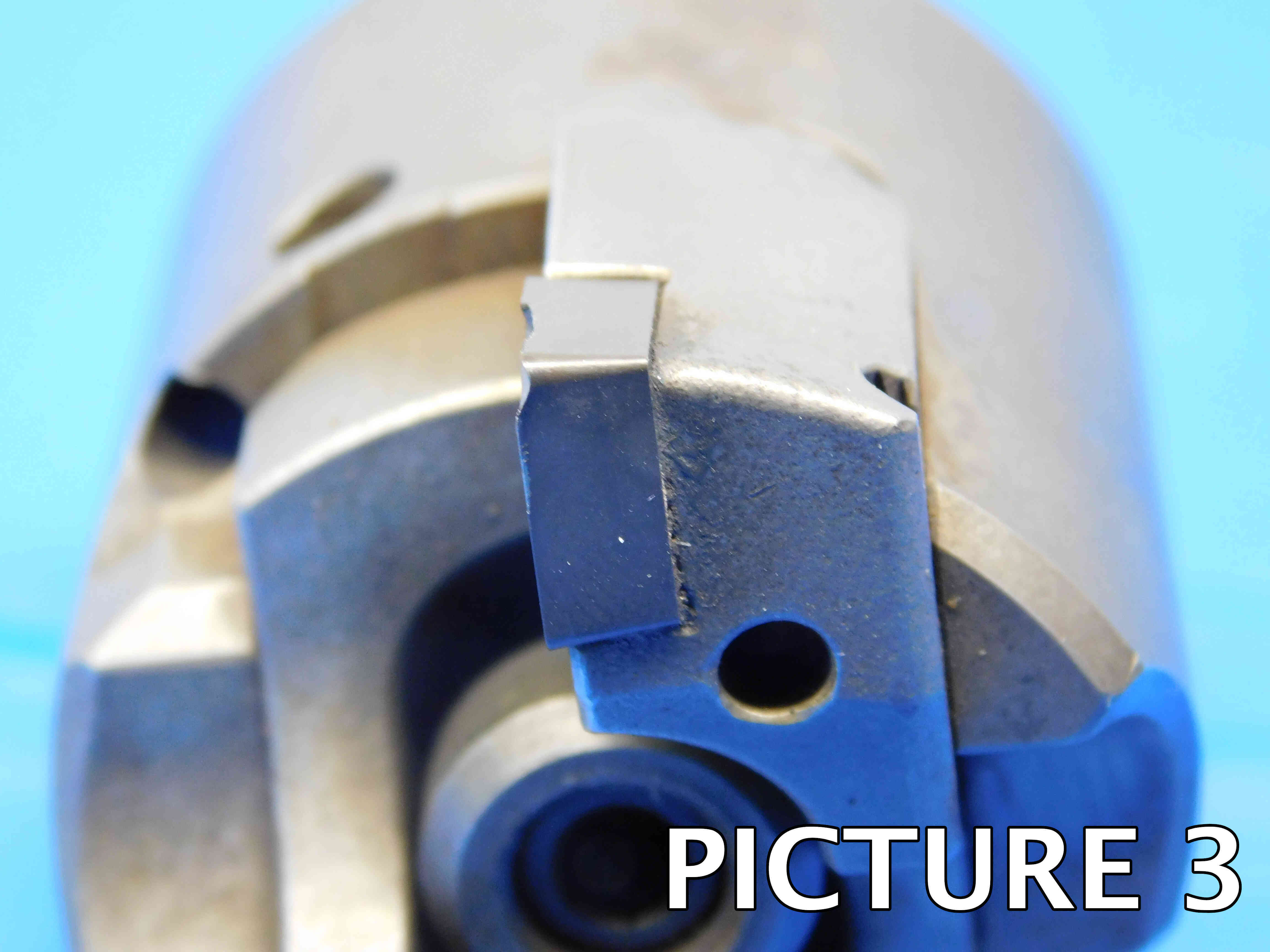

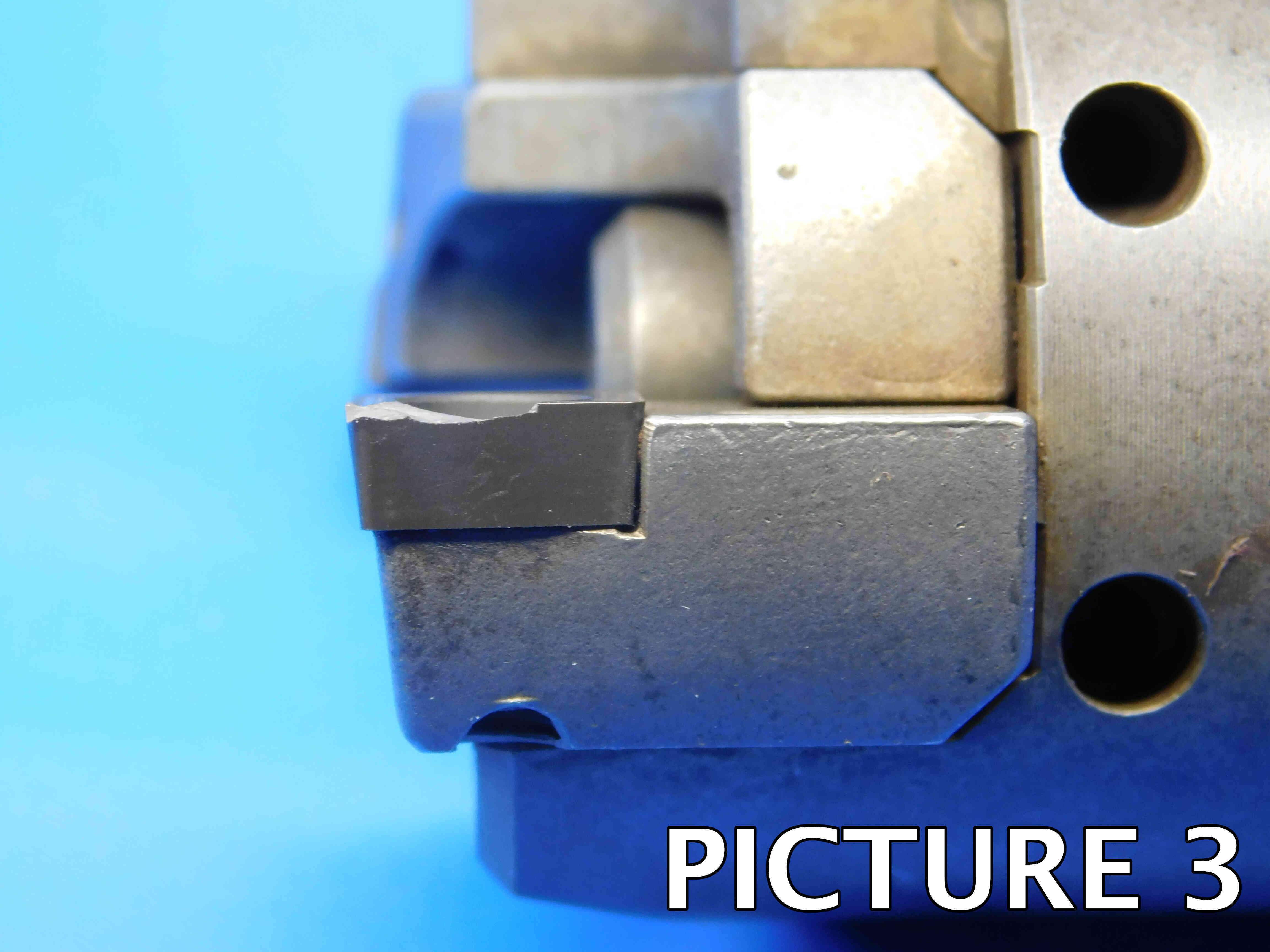

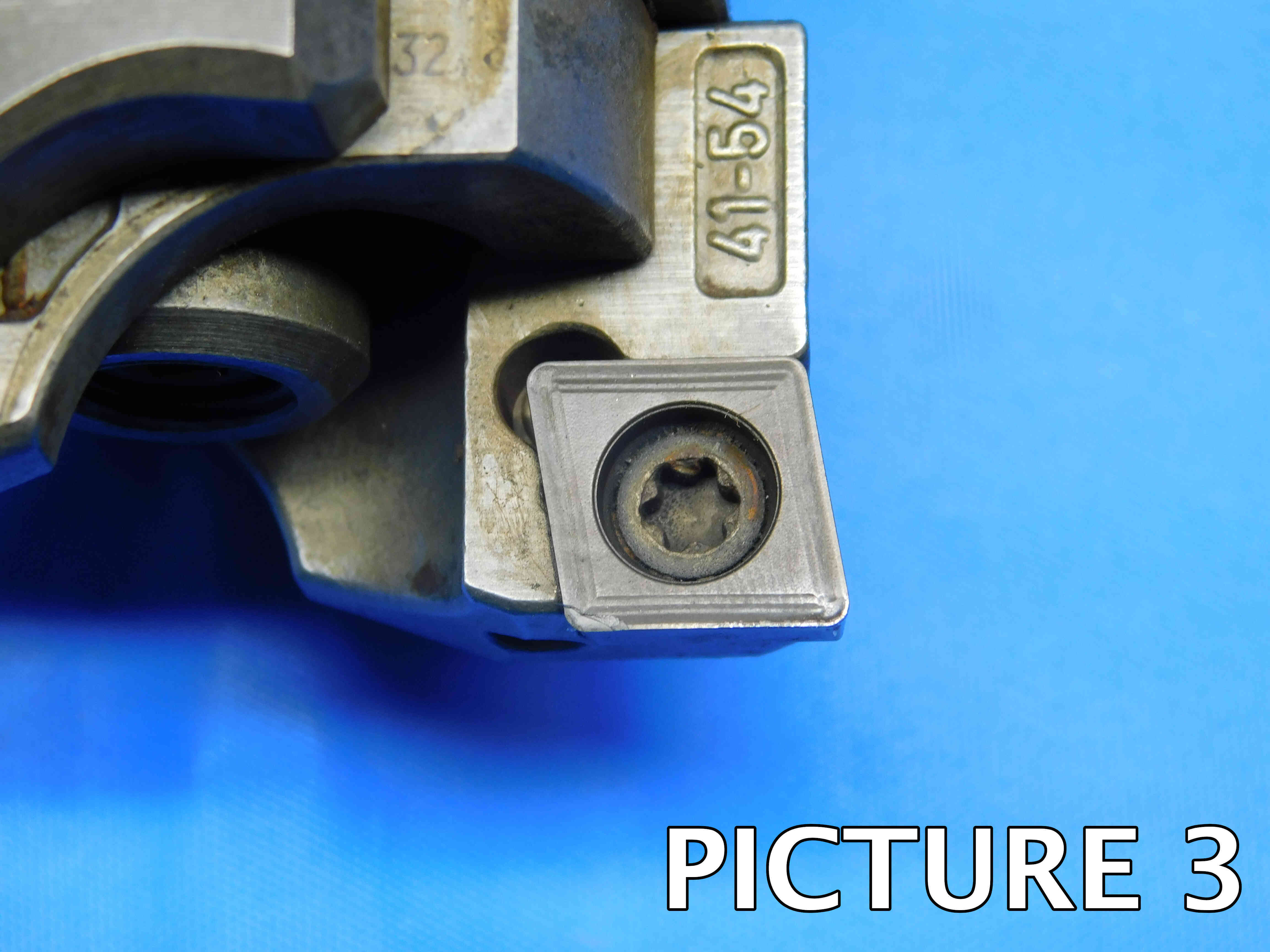

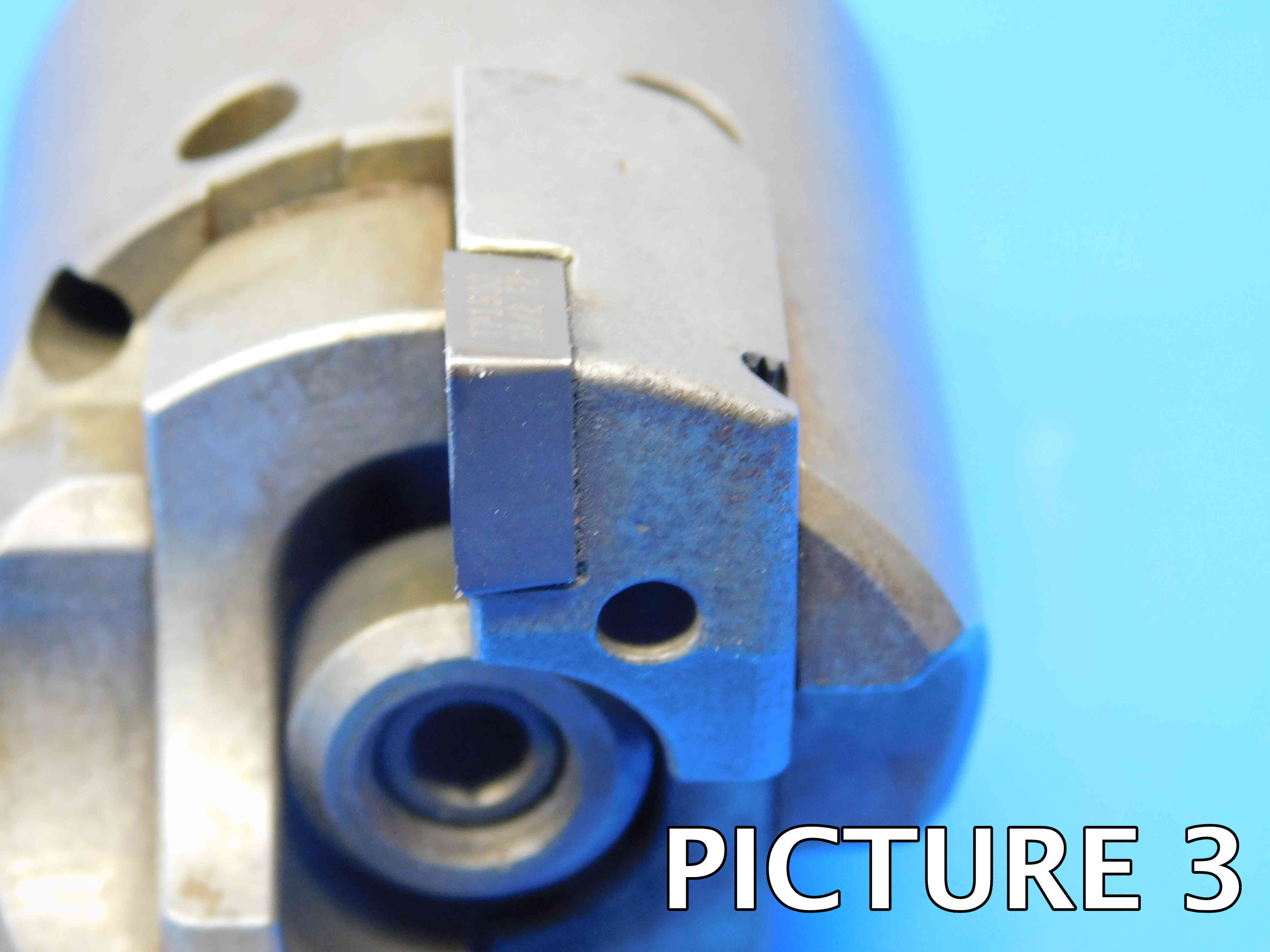

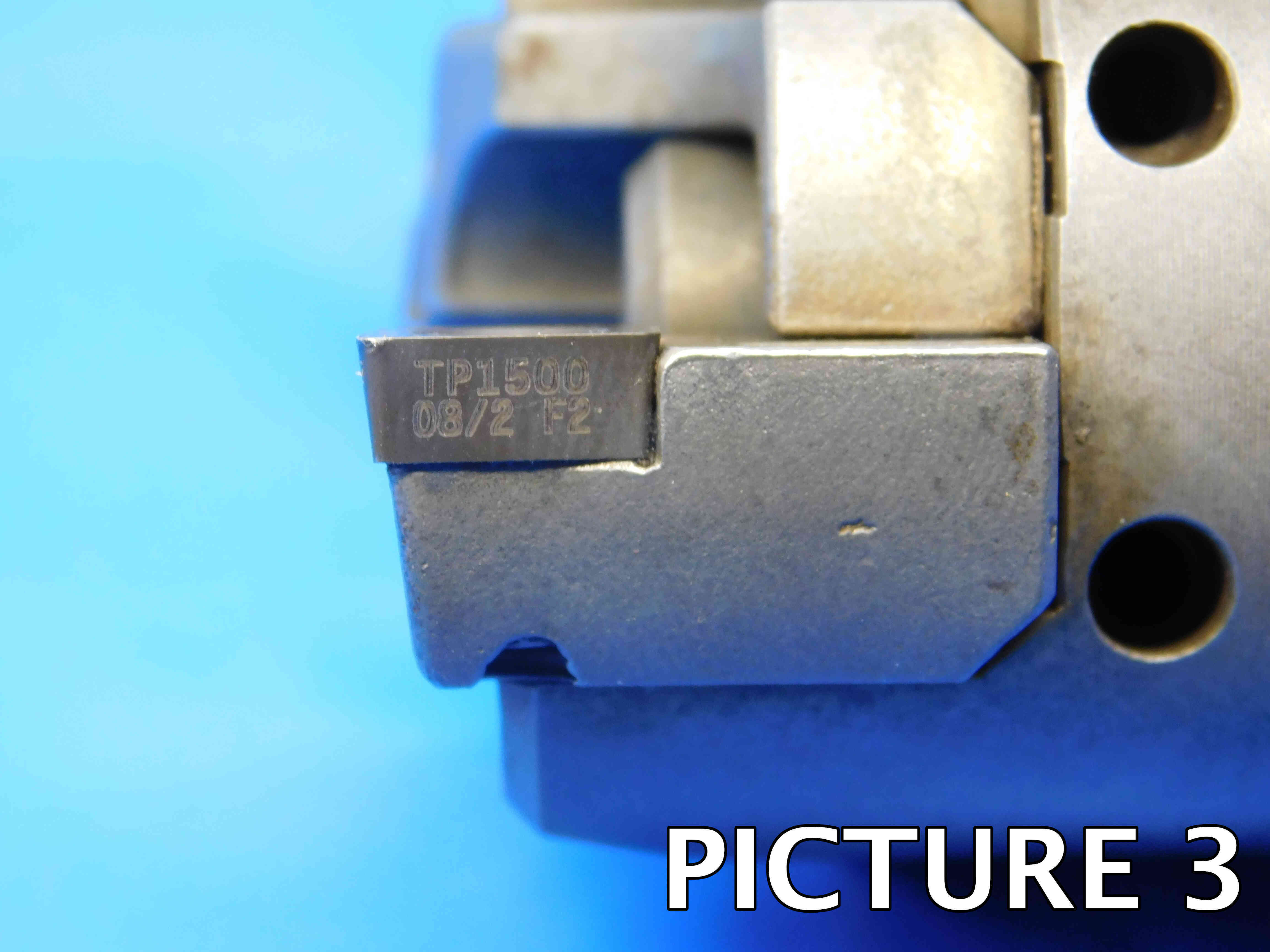

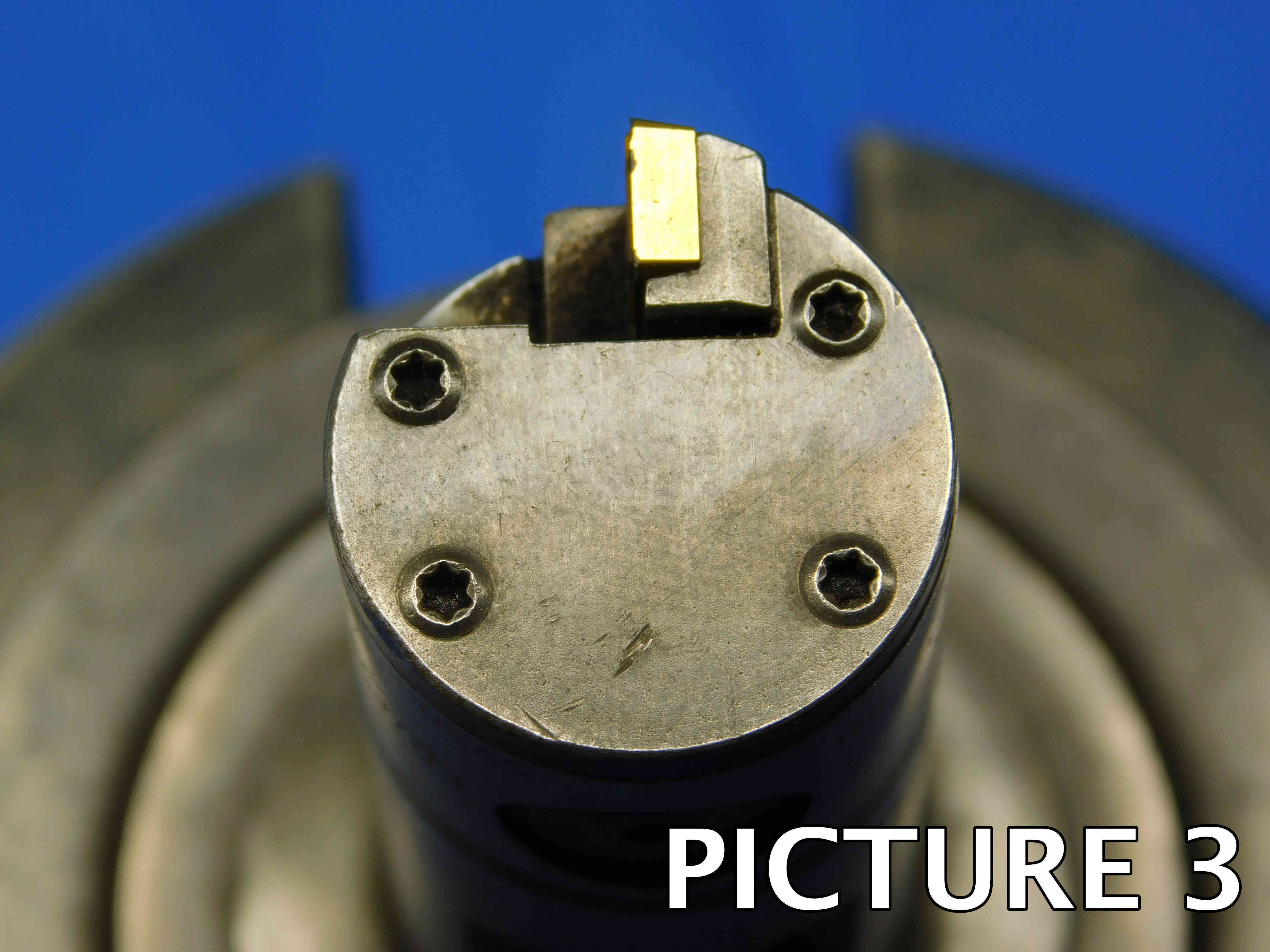

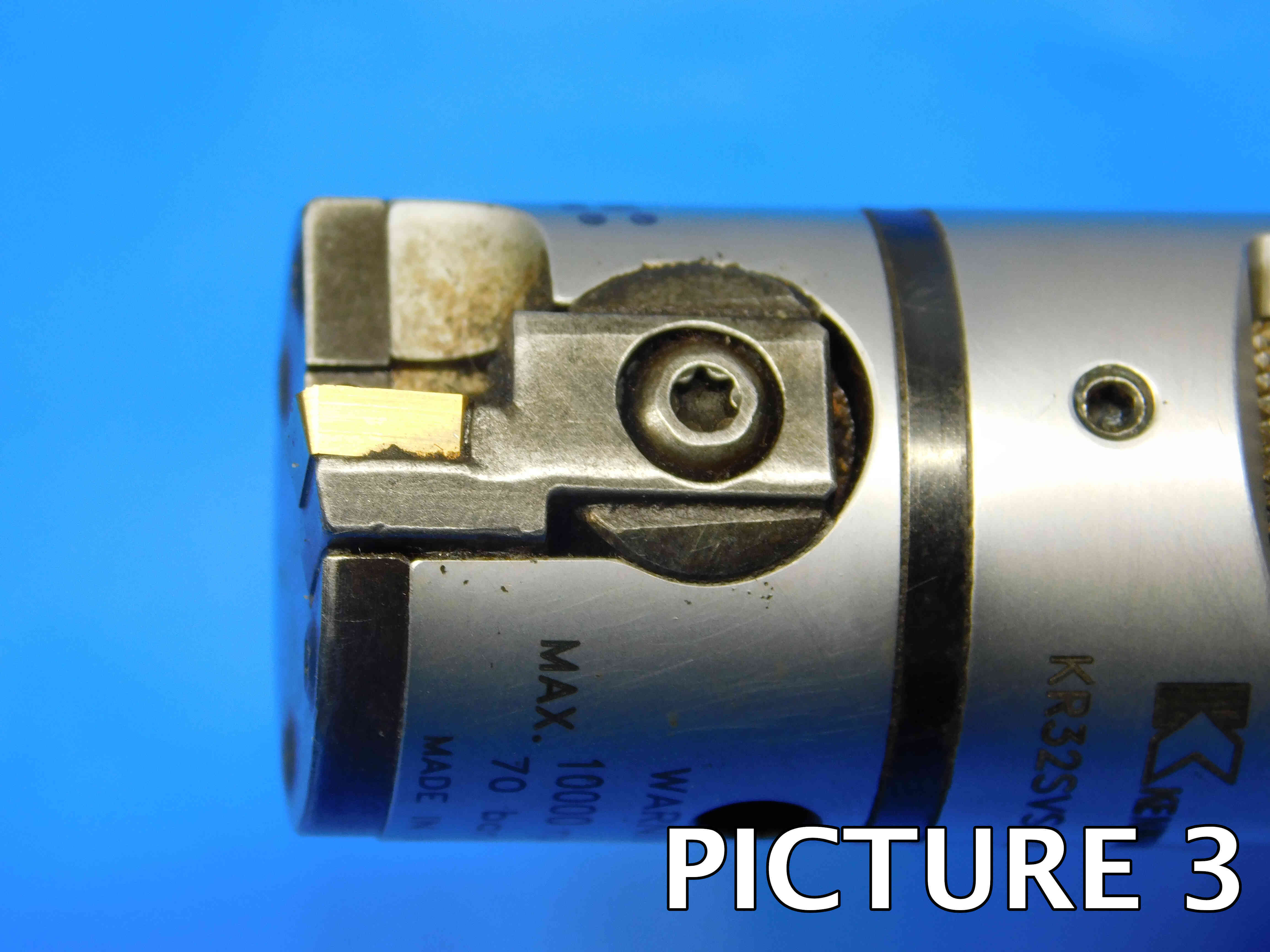

3rd Picture: A close-up, head-on shot of the working end. If the boring head is indexable, you will instead need to take three pictures of the insert pocket(s) from specific angles:

- Top-down

- Head-on, turned 90 degrees so that the bottom of the pocket is visible

- Side view

All three pictures must be present on all used indexable boring heads and must match the examples shown below! The insert pocket is the most important part of the tool and the condition must be 100% clear in the pictures! ***If a boring head is NEW, you may skip the head-on and side-view pictures as there will be no wear / damage that needs to be shown***

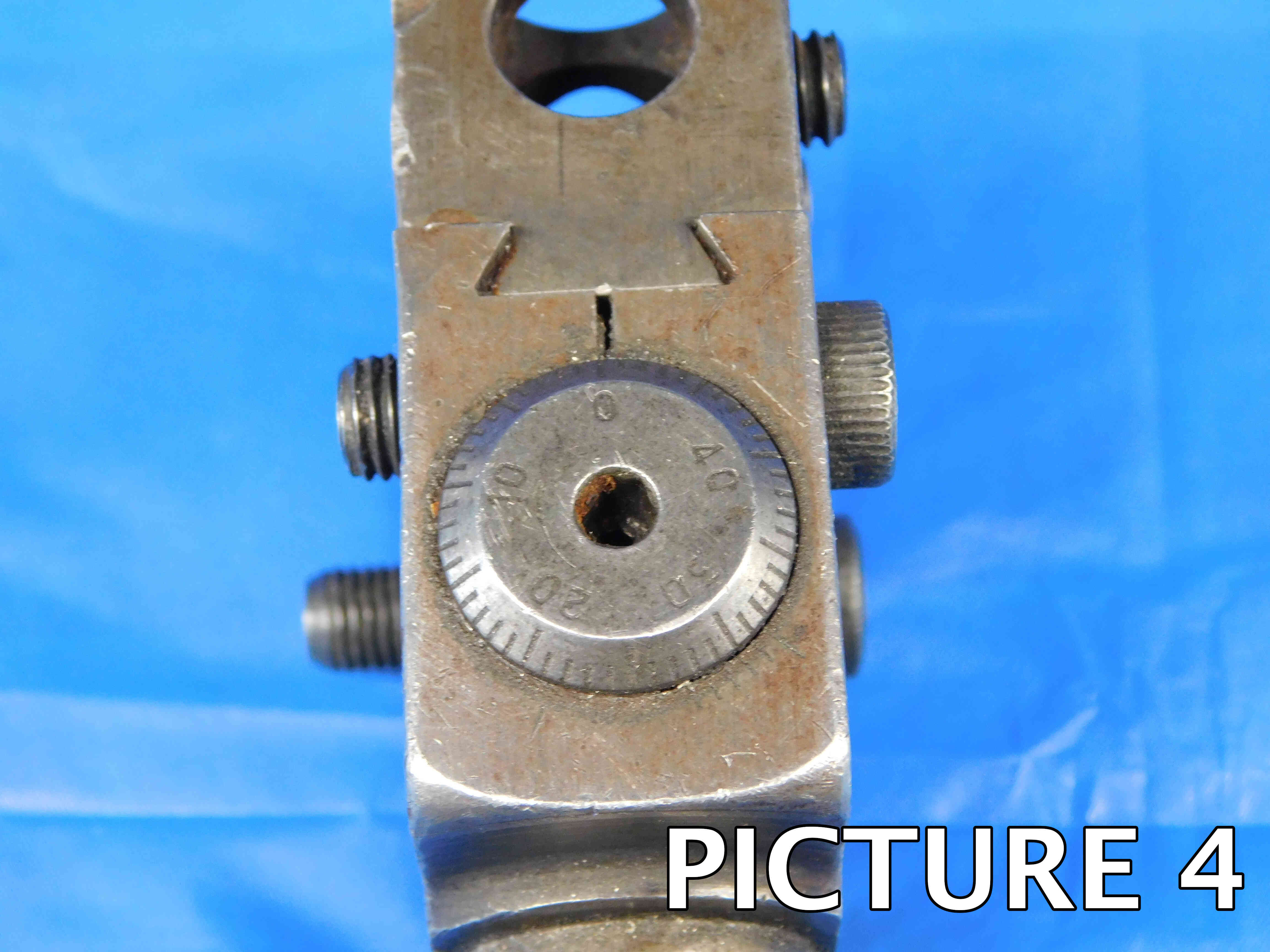

4th Picture: A close-up shot of the adjustable dial (if there is one). If no dial is present, skip this picture.

5th Picture: A close-up shot of the labeling. Depending on the size of the boring head and the location of the labeling, this may require more than one picture. If there is no labeling, or if it is too faded too show up in a picture, skip this picture.

Additional Pictures: Any damage or modifications, especially to insert pockets or the shank / connection side, must be clearly pictured. Use a pen to point to the damaged / modified areas. If there are any flat sections on the shank (whether manufactured or modified) which are not clearly visible in the previous pictures, they should be shown in an additional picture as well. If you think you may need additional pictures for any other reason, check with your trainer to see if they are necessary.

Please refer to the examples below:

Some common boring head brands include Kaiser, Parlec, and Komet. If there is no labeled brand, click the "Unlabeled" button to the right of this cell. Make sure this is not left blank, or the listing will not upload properly. Note: Items are often labeled with the country of origin (USA, China, Japan, Poland, etc). This should NOT be entered as the brand, and furthermore should not be included in the listing at all EXCEPT for USA which can be used as a filler.

Enter any part numbers or other important labeling exactly as it appears on the boring head. This does not include the diameter range or graduation (explained below), as these will be covered by other sections.

Boring heads will fall into one of two categories: Rough and Fine.

Rough (or Roughing) Boring Heads, also called Twin Boring Heads, have two cutting edges and are less precise than fine boring heads. The dual cutting edges allow these heads to remove material more efficiently, but typically a fine boring tool will be needed to precisely bore out the hole to the final size.

Fine (or Finish / Finishing) Boring Heads have only a single cutting edge which allows for more precision. These will typically be used as the last step in the boring process after the hole has been drilled & bored most of the way by a rougher tool. Please note that non-indexable boring heads with I.D. holes for holding boring bars (shown in the 3rd image above) also fall under this category, since the bar it holds will (almost always) only have a single insert.

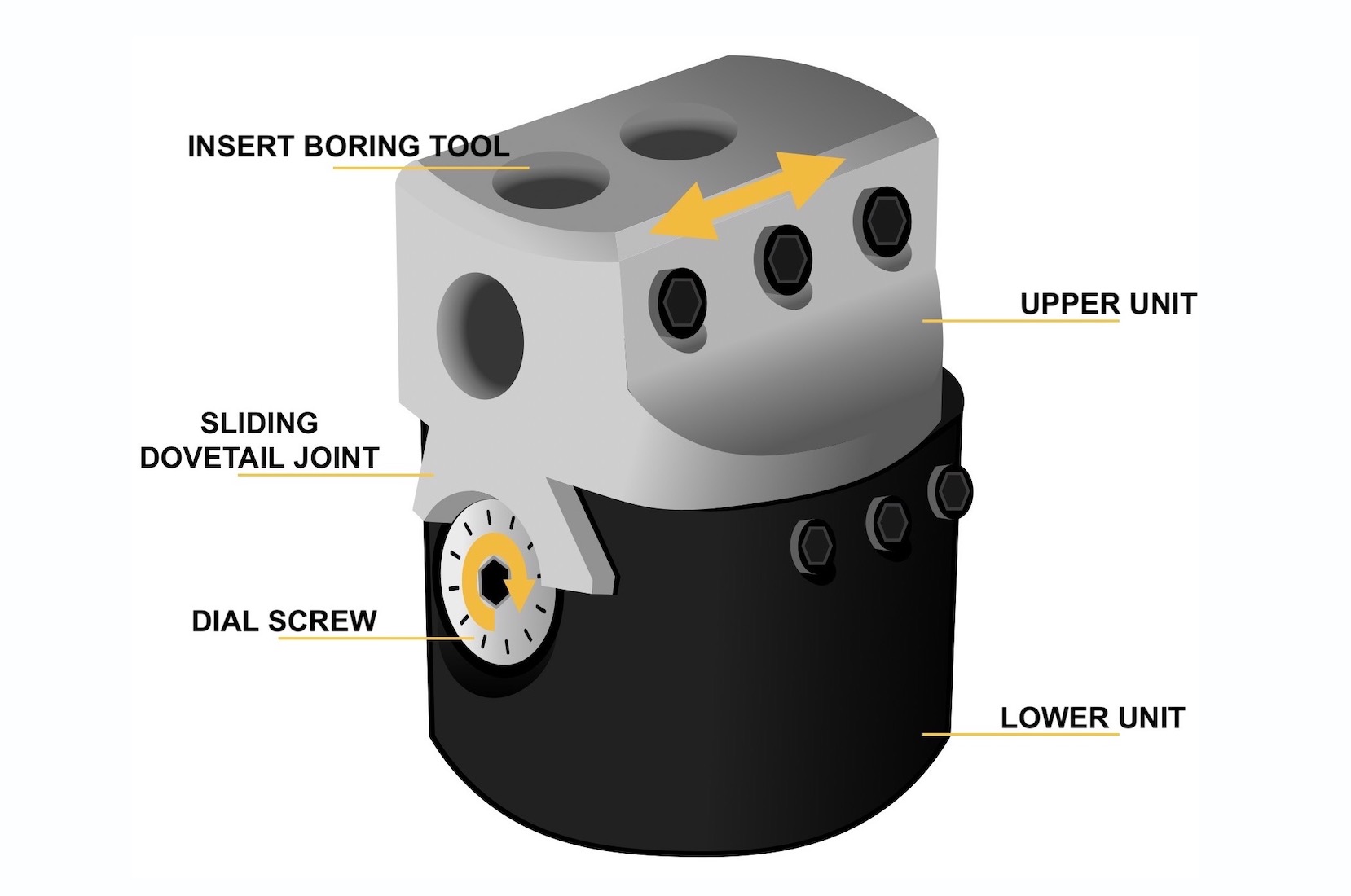

Offset Boring Heads are a sub-category of Fine Boring Heads. These boring heads feature an adjustable slide which is attached to the base by a triangular dovetail joint. "Offset" does not need to be included as part of the type, but can be added as filler if there is room in the title.

While researching a boring head, you may find other type descriptions - for example, boring heads with particularly small ranges are sometimes advertised as "Micro" boring heads. These additional descriptors can be included as part of the type, or in the "Filler" section (explained further down this page).

All adjustable boring heads have a range of diameters that they are able to bore. This will often be labeled, frequently in both inches and millimeters. If the diameter range is not labeled, you may be able to find this information by searching the part number online and looking for a manufacturer's website or catalog, or a webstore listing from a reputable distributor.

Note: Boring heads that hold a boring bar will typically not be listed with diameter ranges, as this is largely dependent on the length of the bar that it is used with.

If labeling and online research do not provide the diameter range, it may be determinable by taking measurements. The exact process for this will vary depending on the type and configuration of the head, but the general procedure is:

1. Set the boring head to its smallest possible diameter. This will typically be done by adjusting a screw using an Allen wrench.

2. Measure the diameter using calipers.

For twin boring heads, this is a simple measurement across the two cutting tips / inserts such as in the image below:

For boring heads with a single cutting edge, this is a little more complicated and the exact procedure will depend on the specific head.

Some boring heads will have a small machining hole in the center of the head, such as the one shown below. For these heads:

1. Measure from the edge of the insert / cutting tip to the outer edge of the center hole. Multiply this number by 2.

2. Measure the inner diameter of the center hole. Add this to the number you calculated in step 1, which will give you the diameter.

If there is not a center hole present, measure from the edge of the insert / cutting tip to the center of the head, which you will have to approximate. Multiply this number by 2, which will give you the diameter.

3. Set the boring head to its largest possible diameter, then repeat step 2 to measure this diameter.

4. Enter the range in the template, including the word "approximately" which can be abbreviated as "APPROX.". For example: APPROX. 2.087 - 2.756"

You may encounter boring heads which cannot be measured using the methods described above. Contact your supervisor if you are not sure how to measure the boring range.

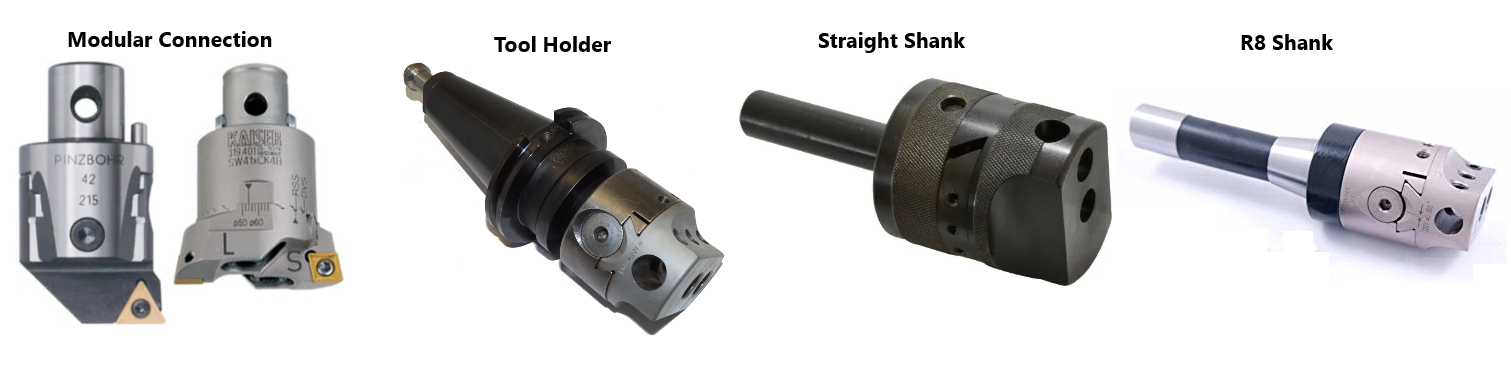

Boring heads come with a variety of shank styles. Many will have modular connections such as ABS or KAB - for more information about modular systems and how to identify them, refer to this page: Modular Connection Types and Size Charts

Boring heads are also frequently attached to taper shank tool holders. In this case, the taper style and size (such as CAT50 or NMTB40) can be entered as the shank type. For more information about tool holders and how to identify them, refer to this page: Tool Holder Information

If a boring head has a straight shank, it can simply be measured with calipers. This will likely be a common size, but this is a precise measurement and should not be rounded if it is more than .005" off from a fractional size.

Another shank type you may encounter is an R8 shank. This is a special shank designed for milling machines with an R8 spindle. This shank type will be tapered at the base of the boring head, and tapers down to a straight diameter of .95".

If you encounter a boring head with a connection / shank that does not fit into any of these categories, describe the shank as accurately as you can, and use the "Additional Specifications" if more space is needed for descriptions or measurements.

Boring heads like the ones pictured above are designed to hold a boring bar, and can be adjusted to alter the boring diameter of the bar. These often have two or more holes which allow the bar to be held either horizontally or vertically, such as in the first and third examples shown above.

The inner diameter of these holes can be measured with calipers. This will often be a common size, but this is a precise measurement and should not be rounded if it is more than .005" off from a standard fractional size. If you are getting an unusual off-size measurement, try converting it to millimeters as it may be a metric size.

Note: When entering a whole-number inch size, always include the " sign. The " sign should not be included for any size including a fraction or decimal. So, for example: If a boring head's hole diameter is exactly one inch, it should be entered as 1" and not just 1. If the hole diameter is one and a half inches, it should be entered as 1 1/2 or 1.5 and not 1 1/2" or 1.5".

Metric size measurements should be entered with a lowercase "mm" (ex.: 16mm, 40mm).

If a boring head does not hold boring bars (such as heads that use indexable boring cartridges), this section should be left blank.

Graduation refers to the divisions of a measurement scale. In other words, this is the distance represented by each line on a boring head's adjustment dial.

The graduation will often be labeled (commonly including the abbreviation "DIV") and will typically be a very small number such as .001". If the graduation is not labeled, you may be able to find it by searching the part number online and looking for a manufacturer's web page or catalog, or a listing by a reputable distributor.

If you are not able to determine the graduation, or if there is no applicable adjustment dial, this section can be left blank.

The word "Indexable" refers to tooling that uses replaceable inserts as the cutting material. Indexable tools are very popular in the machining world because inserts can simply be replaced when they become worn down without needing to replace the entire tool.

When listing boring heads, we are using the term "Indexable" to specifically refer to boring heads that hold inserts directly, such as the ones pictured above. Boring heads that are designed to hold boring bars should not be described as indexable, even though the bars they hold will often be indexable themselves.

Many indexable boring heads use replaceable insert cartridges which can be swapped out for using different types of inserts. Because of this, it can be difficult to find information on the specific inserts held. If the cartridge is labeled with a unique part number, you may be able to search this number to find insert information. Otherwise, the type of inserts can be determined using measurements as explained here: Identifying Inserts FAQ

The "Filler" section is used to add other relevant information to the title which is not covered by the other sections. Fillers can be a good way to increase a listing's visibility - we always want to include as much information as possible that we think a customer might be searching for in order to make sure that our listing is coming up in their search results.

There is not necessarily one right answer when it comes to fillers, and often it will be up to you to decide what should and should not be added as filler. Boring heads generally do not require much filler, but some possible fillers include:

-Secondary Labeling / Part Numbers

-"USA" or "USA Made" for any US Manufacturer (you may need to quickly research a brand if you are not sure, since this is not always specifically labeled)

-Type filler: "Twin" and "Roughing" can be included for Rough Boring Heads, and "Finish" or "Finishing" can be included for Fine Boring Heads

Note: Keep in mind that titles have a maximum limit of 80 characters.

Additional Specifications & Special Condition

The Additional Specifications section should be used for any secondary labeling or additional measurements that do not fit in the other sections of the listing. There is no character limit here so any relevant information that is not already covered should be included (within reason - we don't want to overload the listing with unnecessary information, so ask your trainer if you are not sure whether or not to include something in this section).

The Special Condition section should be used for any special notes about the item's condition such as damage or modification. Try to be specific when describing the condition, and reference pictures that point out the damage / modification if applicable. General wear and tear does not need to be mentioned, but anything that will affect the tool's usage should be included here.

Once all information is entered, click here for the next steps.